Three-phase two-pulse-wave high-power pulse current power supply for electrolytic cells and power supplying method

A high-power, electrolytic cell technology, applied in the direction of output power conversion devices, electrical components, etc., can solve problems such as restricting the efficiency of electrolytic current, and achieve the effects of ensuring three-phase balanced power supply, weakening eddy current loss, and high-efficiency electrolytic state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

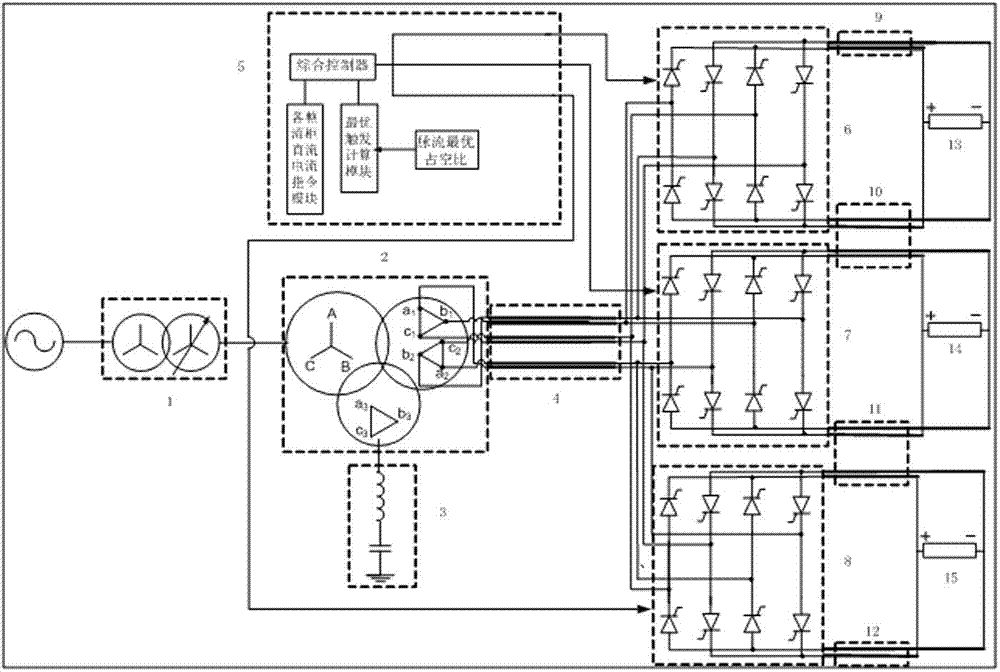

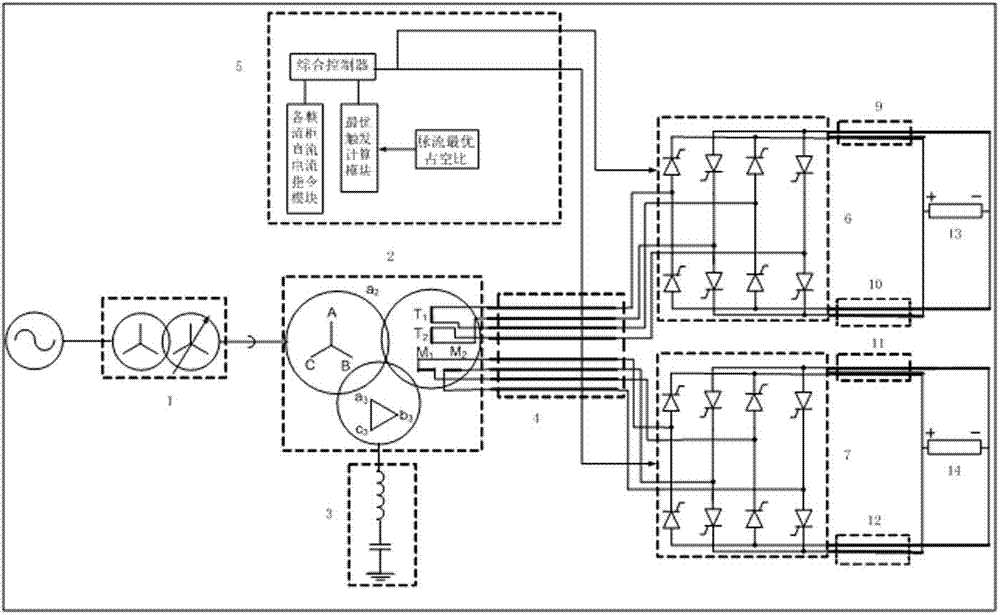

[0018] Such as figure 1 As shown, the present invention includes a three-phase voltage regulating transformer 1, a three-phase induction filter rectifier transformer 2, a three-phase induction filter 3, an in-phase anti-parallel AC busbar 4, a control system 5, a single-phase rectifier cabinet 6~8, an in-phase inverse Parallel DC busbars 9~12, electrolytic cells 13~15, the three-phase voltage regulating transformer 1, the three-phase induction filter rectifier transformer 2, and the same-phase anti-parallel AC busbars 4 are connected in series in sequence, and the three-phase induction filter 3 and the three-phase The phase induction filter rectifier transformer 2 is connected, and the three output ends of the same-phase anti-parallel AC busbar 4 are respectively connected with the inputs of the single-phase rectifier cabinets 6~8, and the outputs of the single-phase rectifier cabinets 6~8 are connected through the same-phase antiparallel DC busbar 9 ~12 is connected to the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com