Motor

A motor and brush technology, applied in the field of motors, can solve problems such as obstacles and increase in the number of components, and achieve the effects of reducing costs, simplifying external structures, and reducing the number of components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] (motor)

[0023] Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

[0024] The electric motor of this embodiment is used as a starter motor of an engine of a motorcycle. When using the electric motor of this embodiment, the rotating shaft is connected with the crankshaft of an engine.

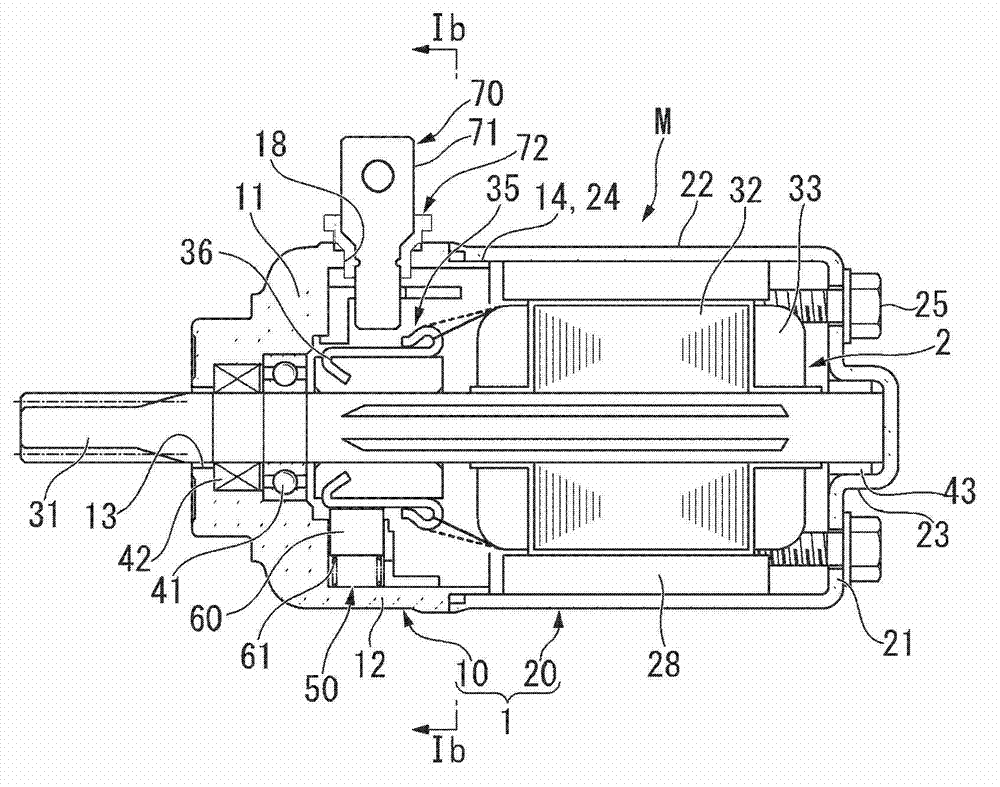

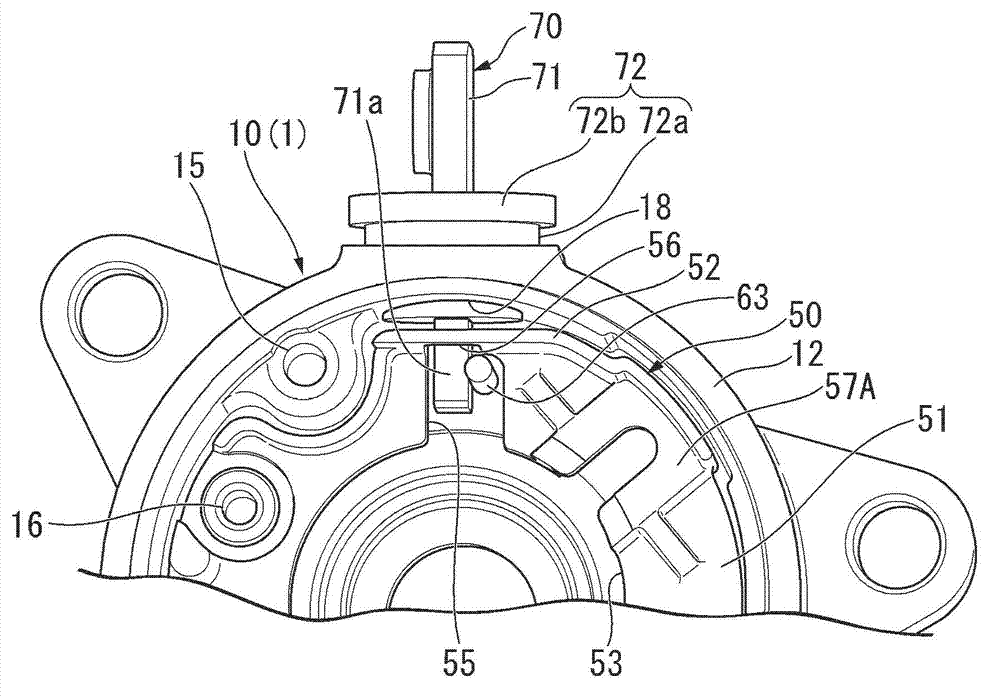

[0025] Such as figure 1 A and figure 1 As shown in B, the motor M includes: a motor casing 1 constituting a stator; a rotor 2 freely rotatably supported on the motor casing 1; The commutator 35 performs switching; the brush 60 makes current flow in the commutator 35 by slidingly contacting the commutator segment 36 of the commutator 35 ; and the terminal 71 supplies power to the brush 60 from the outside.

[0026] The motor case 1 is divided into a front case 10 having a front end wall 11 and a peripheral wall 12 , and a rear case 20 having a rear end wall 21 and a peripheral wall 22 . In addition, in the state where the rear end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com