Low-specific-speed impeller and design method for blade thereof

A technology of low specific speed and impeller, applied in the field of low specific speed centrifugal pump impeller, can solve the problems of unfavorable casting process, shortening pump service life, low pump hydraulic efficiency, etc. Head and efficiency, the effect of improving flow distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

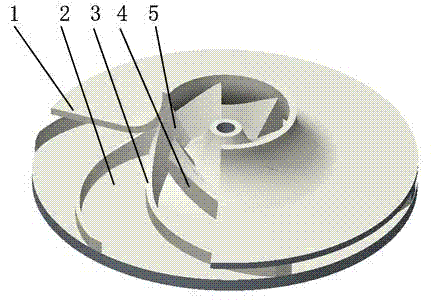

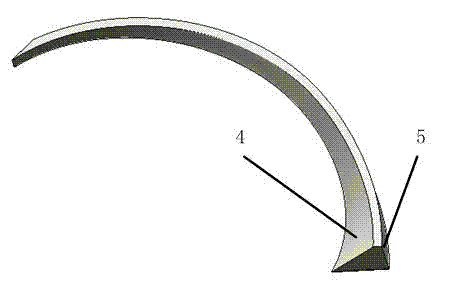

[0026] Such as figure 1 The structural forms of the impeller and its blades shown belong to the closed impeller. Among the working surface 4 and the back surface 5 of the blade 3, one side is a back-bent cylindrical shape, and the other side is a back-bent twist type. figure 2 It shows the situation that the back side 5 of the blade in the design scheme is twisted, and the thickness of the inlet side near the front cover plate is small. According to the performance parameters of the low specific speed centrifugal pump, the geometric parameters of the impeller are calculated to confirm the number of impeller blades, space streamlines and blade thickness. The thickness of the blade near the inlet side of the front cover 1 is 2-3 mm, and the thickness of the blade near the inlet side of the rear cover 2 is 5-7 mm.

Embodiment 2

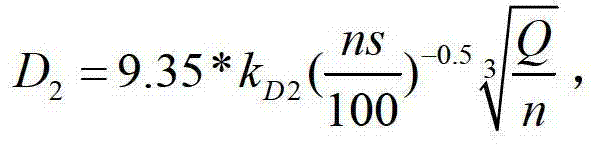

[0028] According to the design parameter Q=30m of a certain low specific speed centrifugal pump 3 / h, H=49m, n=2900r / min, calculate the impeller geometry, including the following steps:

[0029] (1) Calculation of specific revolutions

[0030] n s = 3 . 65 n Q H 3 / 4 = 3.65 × 2900 × 30 / 3600 49 3 / 4 = 53 , It belongs to the category of low specific speed centrifugal pump.

[0031] n is the impeller speed, the unit is r / min;

[0032] ...

Embodiment 3

[0041] According to the design parameter Q=24m of a certain low specific speed centrifugal pump 3 / h, H=32m, n=2900r / min, calculate the impeller geometry, including the following steps:

[0042] (2) Calculate specific revolutions

[0043] n s = 3 . 65 n Q H 3 / 4 = 3.65 × 2900 × 24 / 3600 32 3 / 4 = 64.2 , It belongs to the category of low specific speed centrifugal pump.

[0044] n is the impeller speed, the unit is r / min;

[0045] Q i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com