Twisting adjusting device and method of rope twisting method

A technology of adjusting device and adjusting method, which is applied to auxiliary devices for rope making, textiles and papermaking, textile cables, etc., which can solve the problems of increasing production costs, reducing rope strength, and affecting the state of rope formation, etc., and achieves easy installation and simple design , The effect of low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

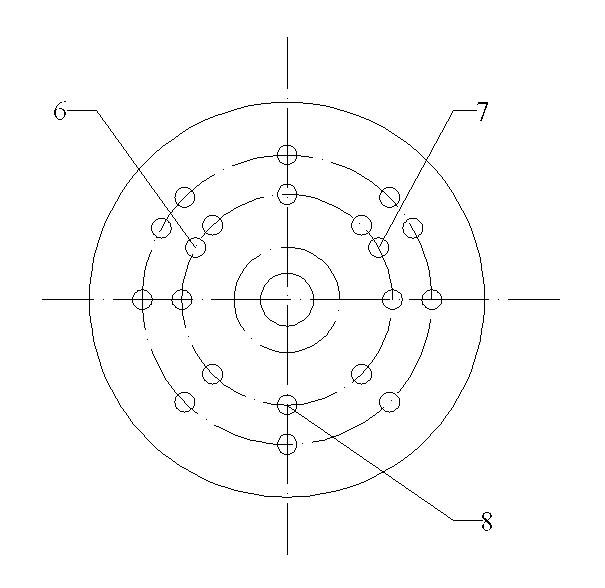

[0019] Such as figure 1 Shown is a specific embodiment of the present invention, the twisting adjustment device of the twisting machine includes a porous disc 1, a fixed bracket 9 and a sleeve assembly 3, one end of the fixed bracket 9 is fixed, and the other end is connected to the sleeve assembly. The sleeve assembly 3 is installed on the bearing inner sleeve 4 through the deep groove ball bearing 5 and the thrust ball bearing 2. The thrust ball bearing 2 is used to prevent the device from being damaged due to too much tension. The deep groove ball bearing 5 can be Allow the turntable to spin freely. The bearing inner sleeve 4 is connected with the porous disc 1 , and the porous disc 1 rotates around the central axis of the bearing inner sleeve 4 along with the bearing inner sleeve 4 .

[0020] Such as figure 2 As shown, the radius of the porous d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com