Energy-saving electric spindle assembly

A technology of electric ingots and components, applied in textiles and papermaking, etc., can solve the problem of large energy consumption of ingots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

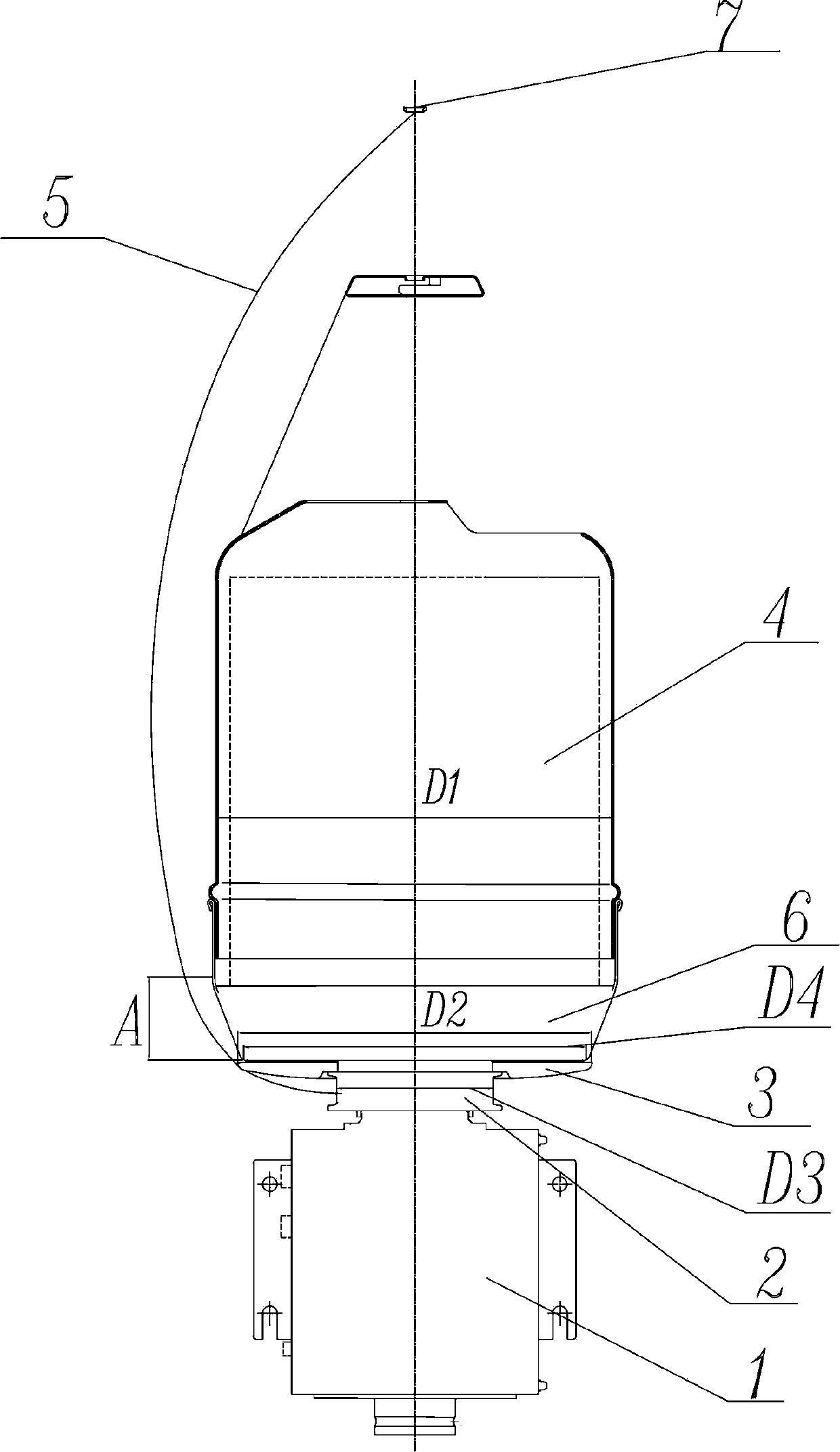

[0023] Such as figure 1 Among them, an energy-saving electric spindle assembly, including: a motor 1, a rotatable yarn storage disc 2 directly connected to the output shaft of the motor, a rotatable twisting disc 3 connected to the yarn storage disc 2, and is arranged on the twisting disc 2 The upper and fixed ingot can 4, the ingot can 4 is used to accommodate the feeding package;

[0024] For industrial yarn with twisting feeding package diameter ≤ φ230mm and yarn fineness range of 840dtex-2600dtex, the minimum diameter D4 of the bottom of the ingot pot is φ210mm to φ215mm, the maximum outer diameter D1 of the ingot pot is φ245mm to φ250mm, the diameter of the twisting disc D2 is φ220mm to φ225mm, and the diameter of the yarn storage disc D3 is φ80mm to φ85mm.

[0025] During the operation of the spindle, the yarn is guided from the yarn storage disc 2 to the twisting disc 3, and then from the twisting disc 3 to the yarn guide 7 above the spindle pot 4. When the spindle spe...

Embodiment 2

[0029] On the basis of Example 1, the minimum diameter D4 at the bottom of the ingot pot is φ210mm, the maximum outer diameter D1 of the ingot pot is φ245mm, the diameter D2 of the twisting disc is φ220mm, and the diameter D3 of the yarn storage disc is φ80mm. When the spindle speed is 8000-9500rpm, compared with the prior art, the energy required to drive the spindle to work is reduced by 13% compared with the known technical solution.

Embodiment 3

[0031] On the basis of Example 1, the minimum diameter D4 at the bottom of the ingot pot is φ215mm, the maximum outer diameter D1 of the ingot pot is φ250mm, the diameter D2 of the twisting disc is φ225mm, and the diameter D3 of the yarn storage disc is φ85mm. When the spindle speed is 8000-9500rpm, compared with the prior art, the energy required to drive the spindle to work is reduced by 10% compared with the known technical solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Minimum diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com