Method of Reducing Surface Resistance Based on Plasma Exciting Device

A plasma and excitation device technology is applied in the field of reducing surface resistance based on the plasma excitation device, which can solve the problem of increasing the stall angle of attack, unable to effectively reduce the turbulent frictional resistance, and unable to interfere with the underlying pseudo-sequence structure of the turbulent boundary layer. and other problems to achieve the effect of reducing the frictional resistance of turbulent flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

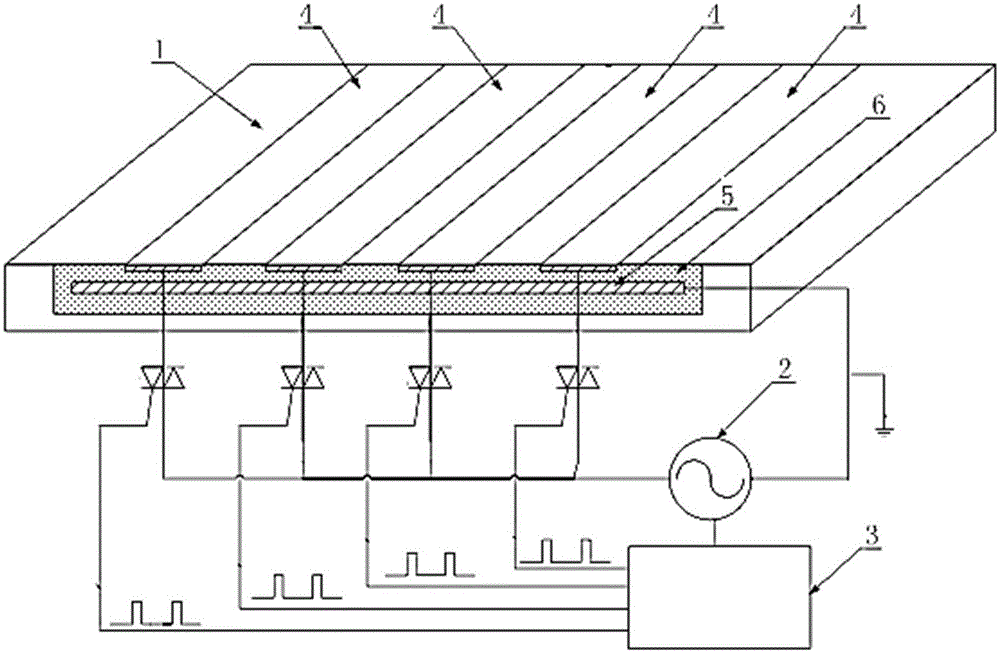

[0031] Such as figure 1 As shown, the device of this embodiment includes: an electrode array arranged on the target plane 1, a power source 2 and a controller 3 for adjusting the parameters of the power source 2, wherein:

[0032] The electrode array includes: a number of exposed electrodes 4 arranged in parallel on the surface of the target plane 1, a buried electrode 5 disposed inside the target plane 1, and an insulating medium 6 disposed between the exposed electrodes 4 and the buried electrodes 5, wherein: The centerlines of the exposed electrode 4 and the embedded electrode 5 are parallel to the incoming flow direction of the turbulent flow;

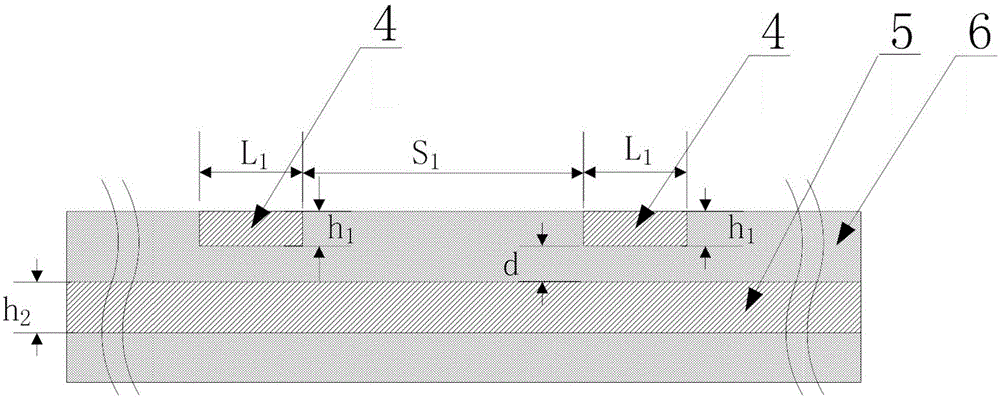

[0033] Such as figure 2 As shown, the structure of the buried electrode 5 is: a monolithic structure whose width includes the entire width of the exposed electrode 4 to generate synchronous induced fluid without phase difference.

[0034] Compared with the prior art, in this embodiment, the adjacent electrodes can generate oppos...

Embodiment 2

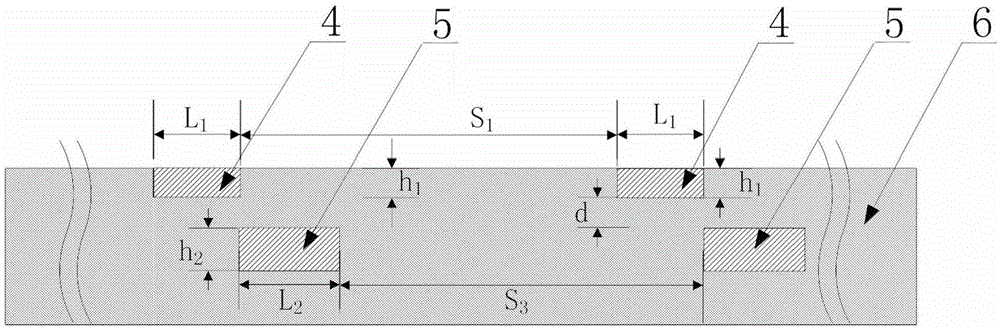

[0044] Such as image 3 As shown, other structures are the same as in Embodiment 1, and the structure of the buried electrode 5 is: a single-side separated structure that is separated into several units and respectively arranged on one side of each exposed electrode 4, wherein: the single-side separated structure In the structure, each embedded electrode 5 unit and each exposed electrode 4 are distributed alternately, and the positions of the respective broad sides of the two electrodes correspond to generate an asynchronous and different-phase induced fluid. In the figure, the width of each embedded electrode 5 unit is L 2 , the spacing between each unit is S 3 .

[0045] Such as Figure 5 , Figure 6 and Figure 7 As shown, the topological structure of the exposed electrode 4 is: a straight line parallel structure, a zigzag structure or a curved structure.

[0046] In the drag reduction method of this embodiment, on the premise that each electrode array can be stably d...

Embodiment 3

[0048] Such as Figure 4 As shown, the other structures are the same as in Embodiment 1, and the structure of the buried electrode 5 is: a double-side separated structure separated into several units and arranged on both sides of each exposed electrode 4, in which one exposed The electrodes 4 respectively correspond to two embedded electrode 5 units, and the wide sides on both sides of the exposed electrode 4 respectively correspond to the broad sides of one embedded electrode 5 unit. At this time, a synchronous induction fluid with no phase difference or an asynchronous out-of-phase is generated. In the figure, the distance between the units of embedded electrodes 5 corresponding to different exposed electrodes 4 is S 2 .

[0049] Such as Figure 5 , Figure 6 and Figure 7 As shown, the topological structure of the exposed electrode 4 is: a straight line parallel structure, a zigzag structure or a curved structure.

[0050] The drag reduction method in this embodiment c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com