Winding device and printing device

A technology of winding shafts and planetary gears, applied in printing and inking devices, etc., can solve the problems of complex structure of tape winding mechanism and increase of manufacturing cost, and achieve the effect of reducing quantity and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

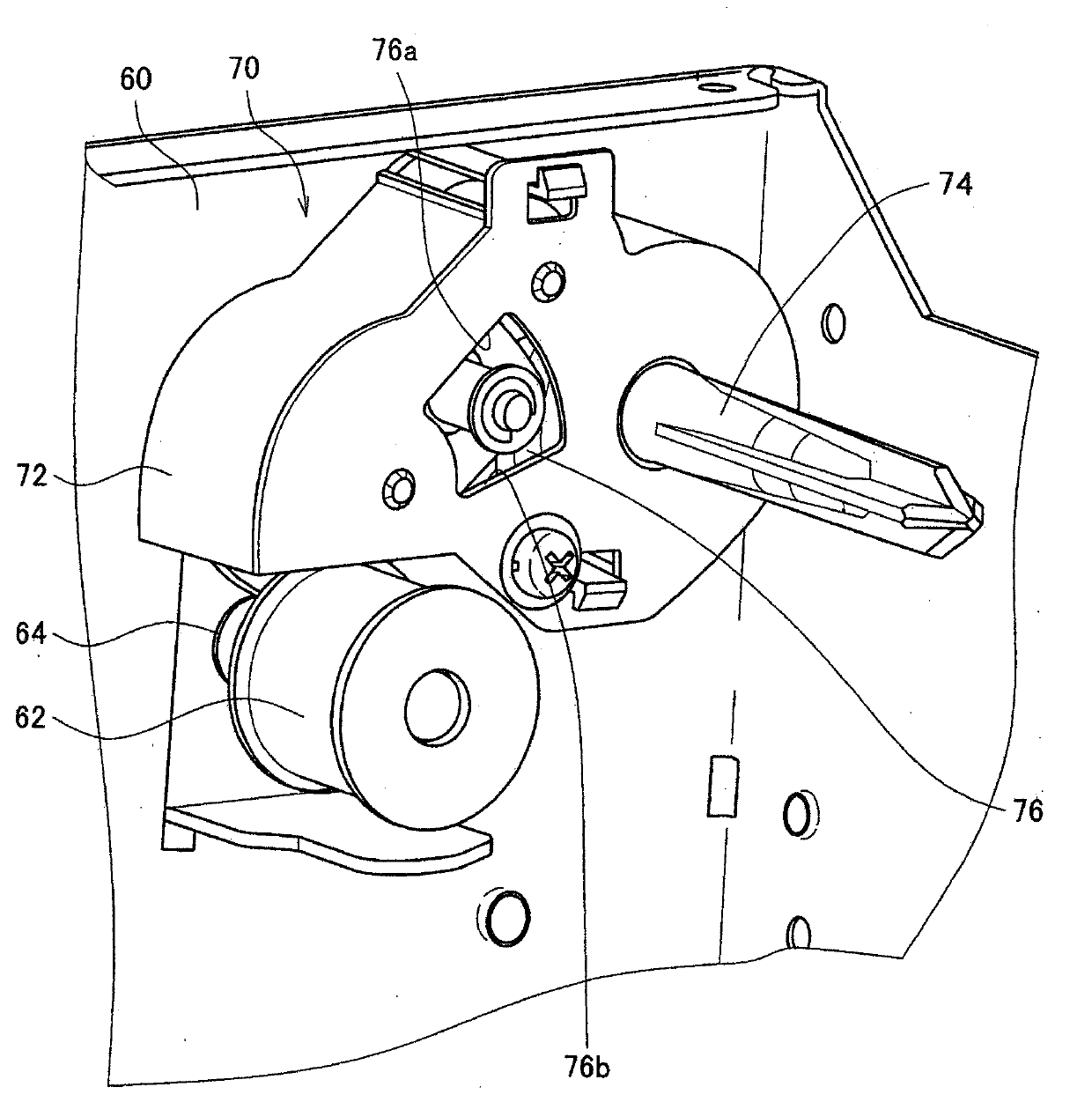

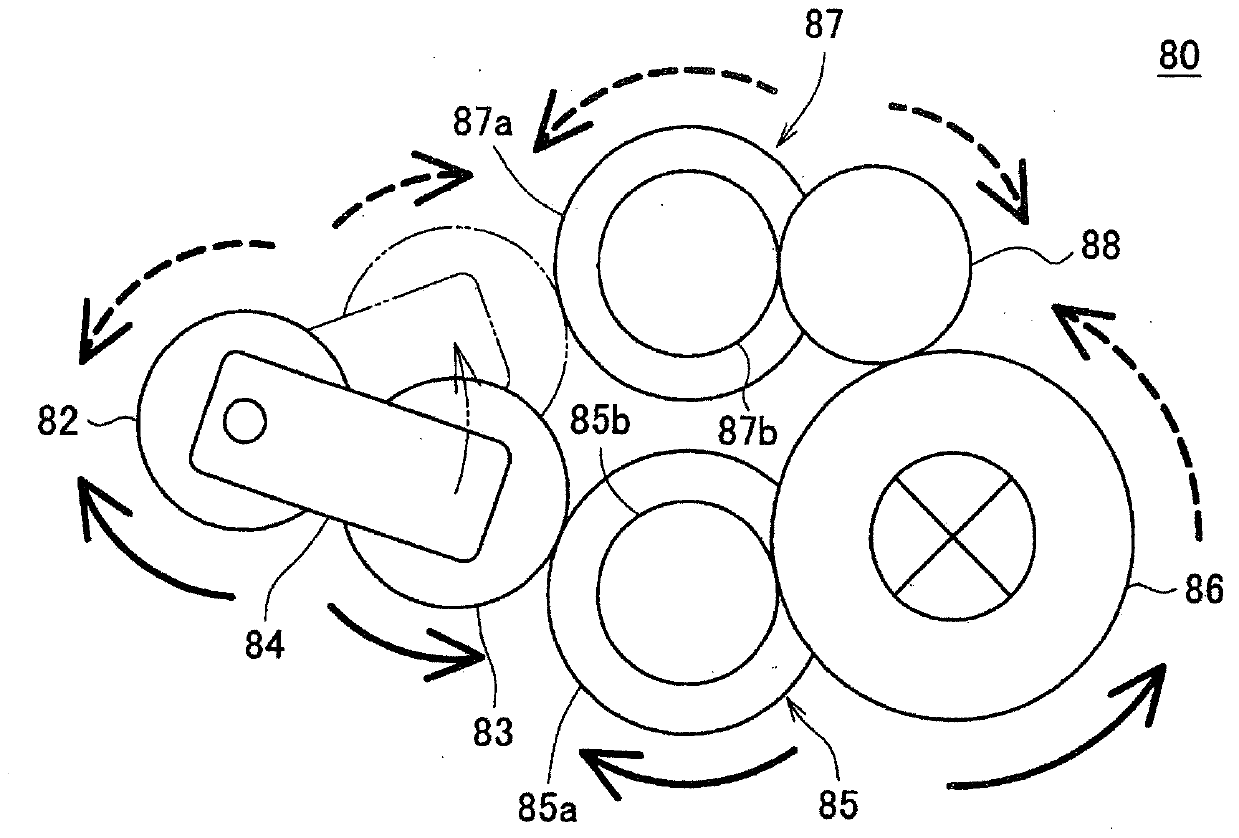

[0027] Embodiments of the present invention will be described in detail below with reference to the drawings. However, in this specification and the drawings, components having substantially the same functional configuration are denoted by the same reference numerals, and repeated descriptions are omitted.

[0028] In addition, in this specification and the drawings, a plurality of constituent elements that actually have the same functional configuration may be distinguished by attaching different letters to the same reference numerals. However, when there is no particular need to distinguish a plurality of constituent elements that actually have the same functional configuration, only the same reference numerals are attached.

[0029]

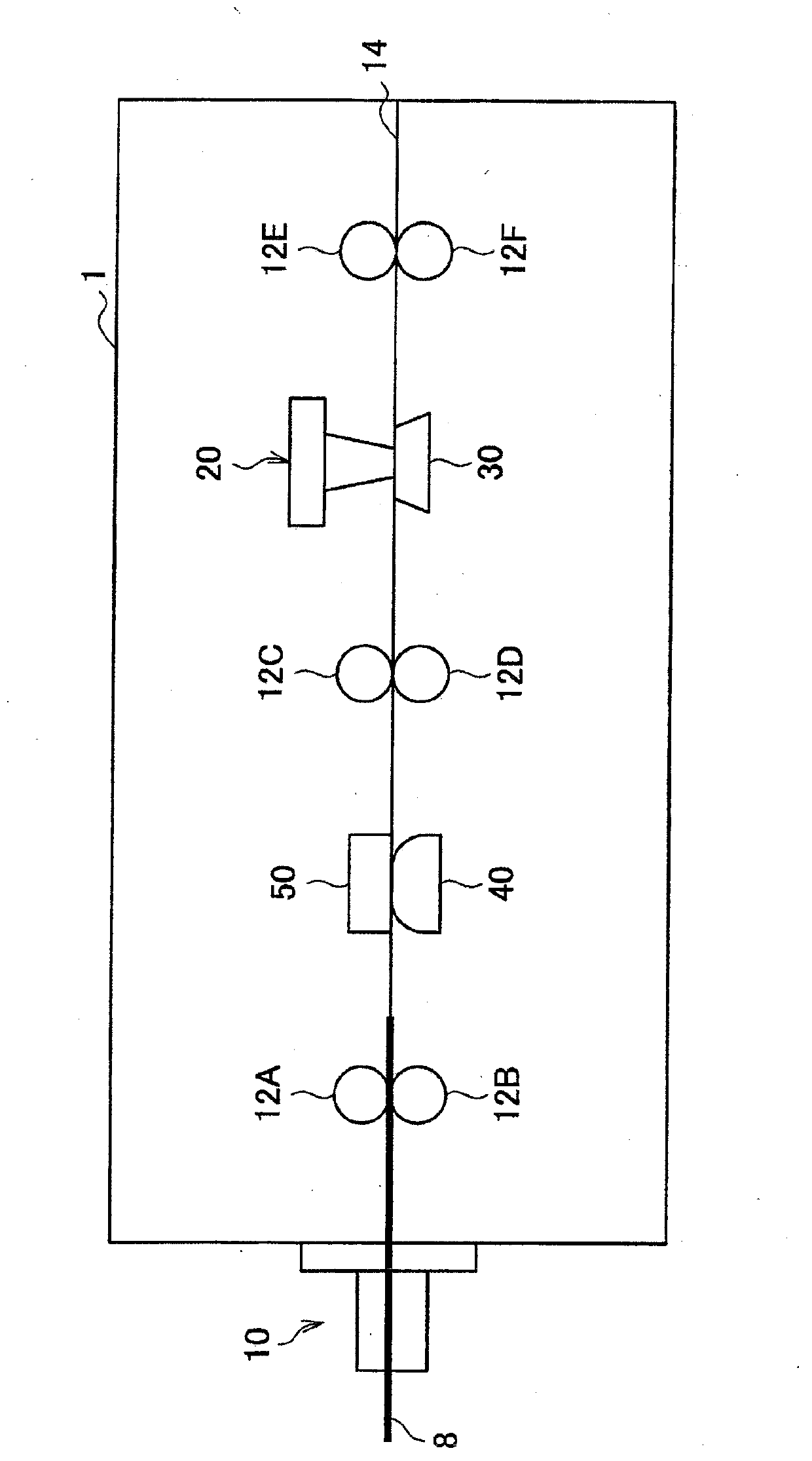

[0030] The present invention can be implemented in various forms as explained in detail below as an example. In addition, in the printing device 1 according to the embodiment of the present invention,

[0031] A. A printing unit ( 20 ) is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com