Electric rivet pulling device

An electric riveting device and rivet clip technology are applied in the field of hand-held tools, which can solve the problems of complicated procedures and damage to rivet attachments, and achieve the effects of reducing manufacturing costs, improving riveting work, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

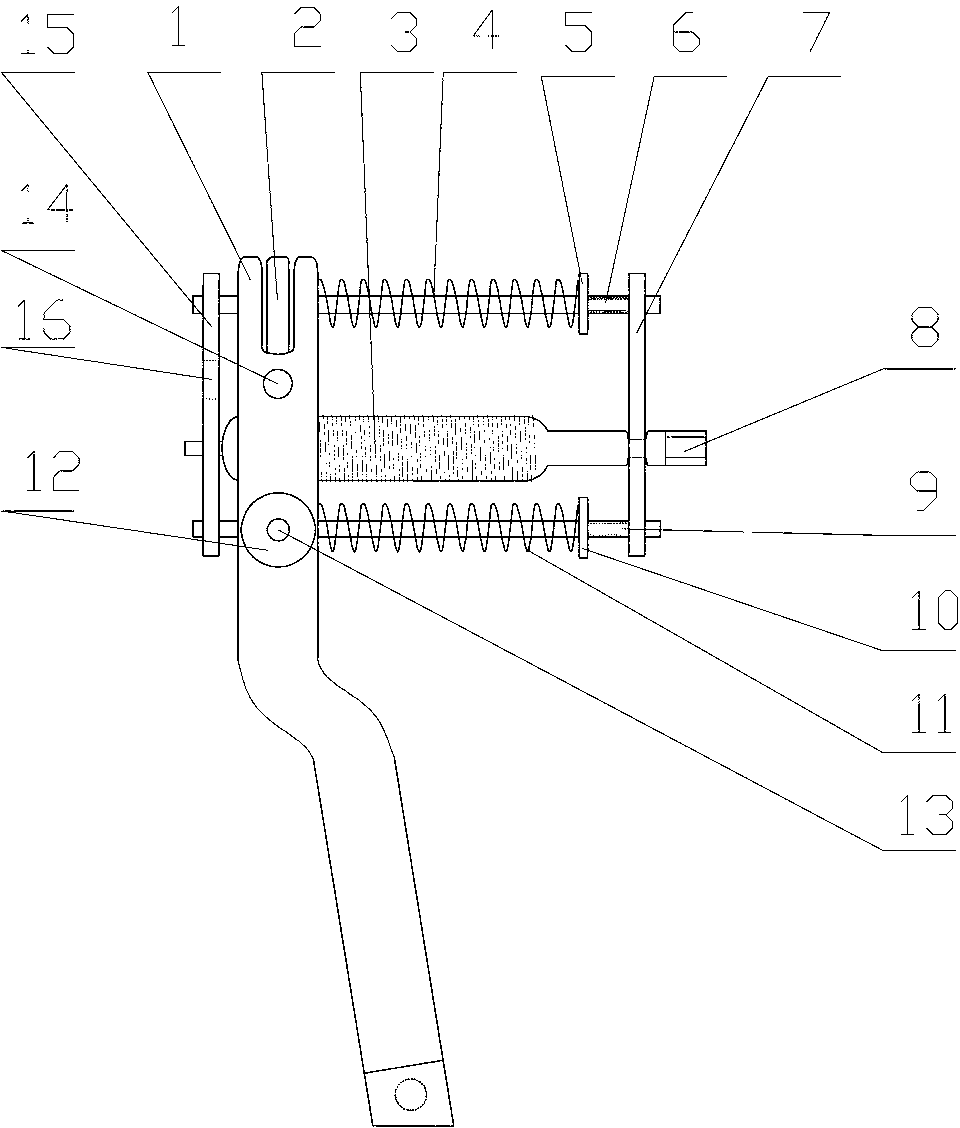

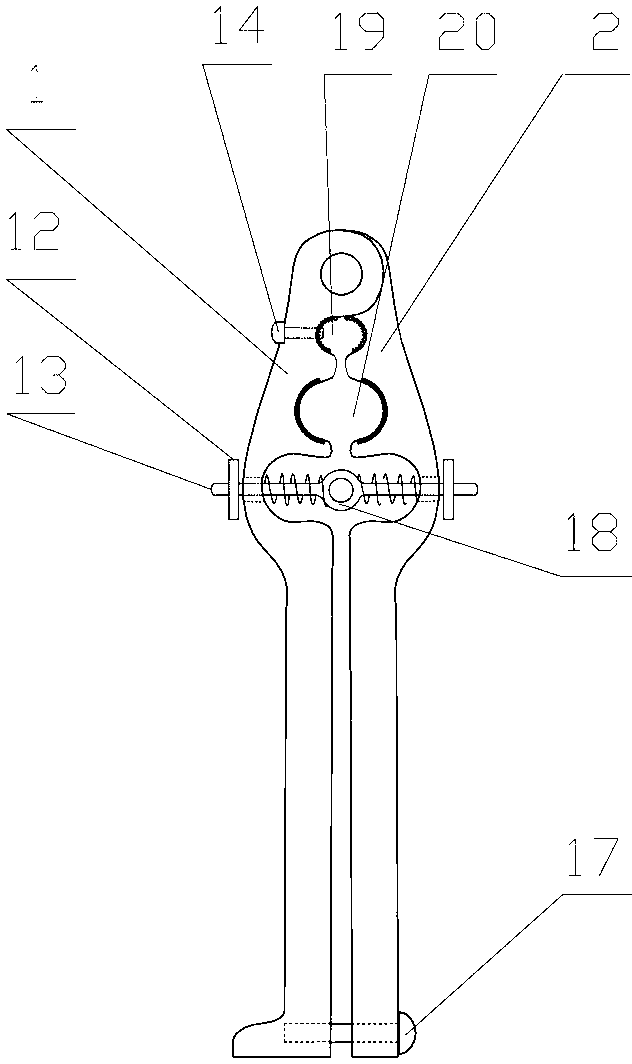

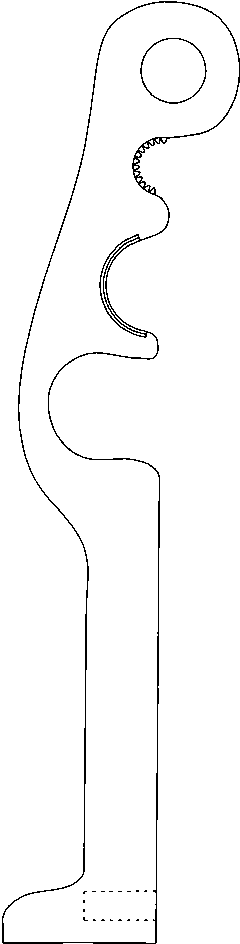

[0024] like figure 1 , figure 2 , image 3 , Figure 4 As shown, an electric riveter includes a hinged left handle 1 and a right handle 2, and the upper part of the opposite side of the left handle 1 and the right handle 2 is respectively provided with two arc-shaped grooves, one of which is There are clamping teeth inside, and threads are processed inside the other arc-shaped groove. Two arc-shaped depressions with clamping teeth form the rivet clamping opening 19, and two arc-shaped grooves processed with threads form the screw sleeve. 20; the screw sleeve 20 is internally threaded with a screw 3; the left section of the screw 3 is thicker as a threaded section, the right section is thinner and the right end is designed as a square connector 8 for use with an electric drill. The two ends of screw mandrel are respectively connected with front fixed plate 15 and rear fixed plate 7, and front fixed plate 15 is positioned at handle left side, and rear fixed plate 7 is positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com