Hand-operated egg beating device

A technology of transmission parts and chambers, which is applied in home appliances, applications, kitchen utensils, etc. It can solve the problems of easy splashing, labor, and high cost of electric egg beaters, and achieve the effect of convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

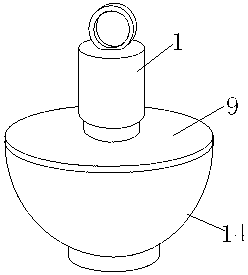

[0024] Such as figure 1 , As shown in 8, the manual egg beating device of the present invention includes a ring cap 1, a transmission part 5, a chamber cover 9, a detachable stirring rod 13, a chamber 14, and the like.

[0025] There is a cavity 10 inside the chamber cover 9 that matches the size of the rotating parts, the transmission part 9 is movably connected in the cavity 10, and the pull ring cap 1 is set outside the cavity 10 of the chamber cover 9, and extends toward the inner eaves through the lower end. The edge 4 of the container cover 9 is fastened to the outer eaves 11 extending outwards from the top of the chamber cover 9, and the long-lead stud 3 inside the pull ring cap 1 is engaged with the thread of the threaded hole 6 of the transmission part 5 or the ball screw and the transmission part The ball screw nuts mesh with each other, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com