A kind of unit row seeding machine

A row and monomer technology, applied in the direction of seeder parts, etc., can solve the problems of seed damage, low degree of mechanization, high labor intensity, etc., and achieve the effect of reducing damage rate, small seed damage and high self-cleaning degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

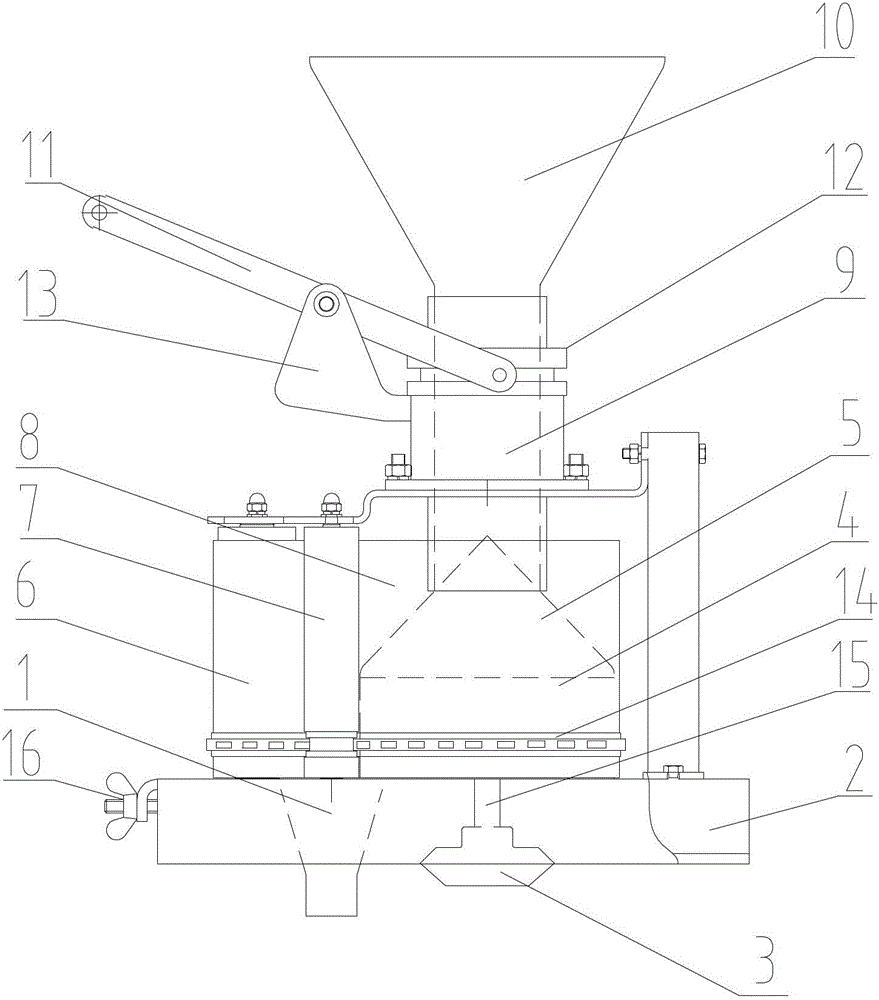

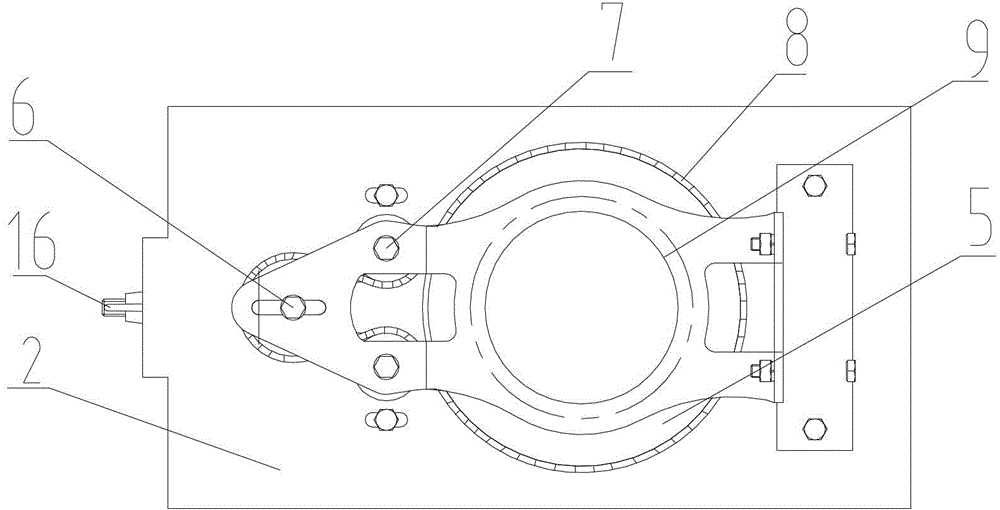

[0021] see figure 1 , figure 2 , a row-row seed drill unit, which is located on the upper part of the row-row drill body, and includes a seed-discharging device and a seed-storing device fixed on the upper part of the body. The seed-discharging device includes a mounting base 2, and one side of the mounting base 2 There is a seed discharge port 1, the body drives the rotating bevel gear 3, the upper part of the bevel gear 3 is sequentially installed with a cone base 4 and a hollow cone 5 linked with it, and one side of the cone 5 is provided with a tension roller 6, The seed discharge port 1 is located between the cone 5 and the tension roller 6, and the periphery of the cone 5 and the tension roller 6 is wrapped with a transmission canvas belt 8; the seed storage device includes a glass seed storage sleeve 9 and a seed storage Funnel 10, the lower part of the seed storage sleeve 9 is closely engaged with the top of the cone 5.

[0022] The seeding device also includes two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com