Front opening wafer container with wafer cushion

The technology of a wafer container and buffer is applied in the field of front opening wafer container with wafer buffer to achieve the effect of reducing possibility and enhancing catchability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

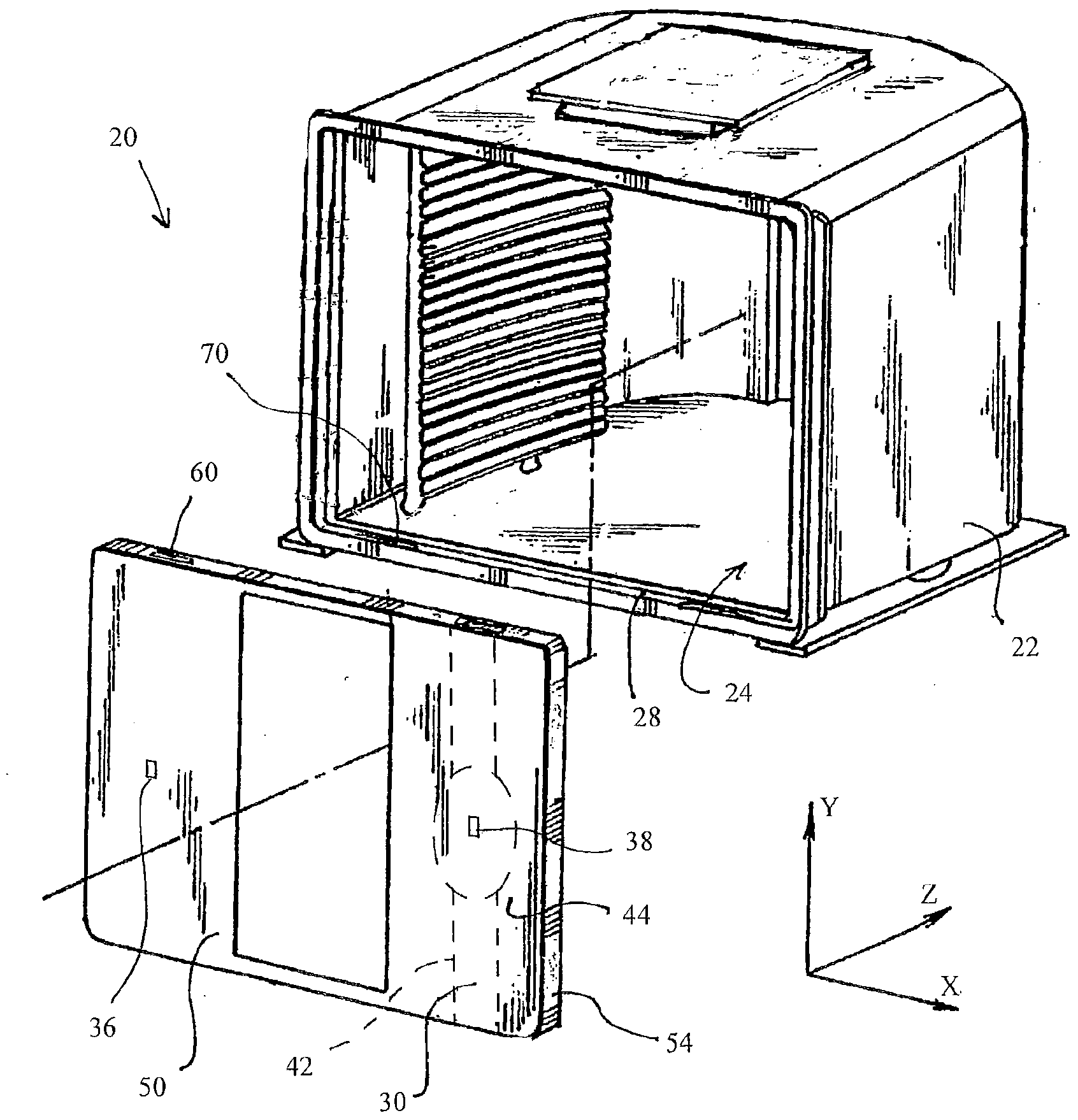

[0035] refer to figure 1 , shows a front opening wafer container 20 that generally includes a container portion 22 having a front opening 24 defined by a door frame 28; and a front door 30 configured to close the front opening. The door has a pair of key holes 36 , 38 for accessing a latch mechanism 42 located inside a door housing 44 . The door has an outer surface 50 , a perimeter 54 and an inner surface 56 . Positioned on the perimeter is a slot 60 that allows the latch tab 64 or tip to extend and retract from the door to engage and disengage with a recess 70 on the inner surface of the door frame.

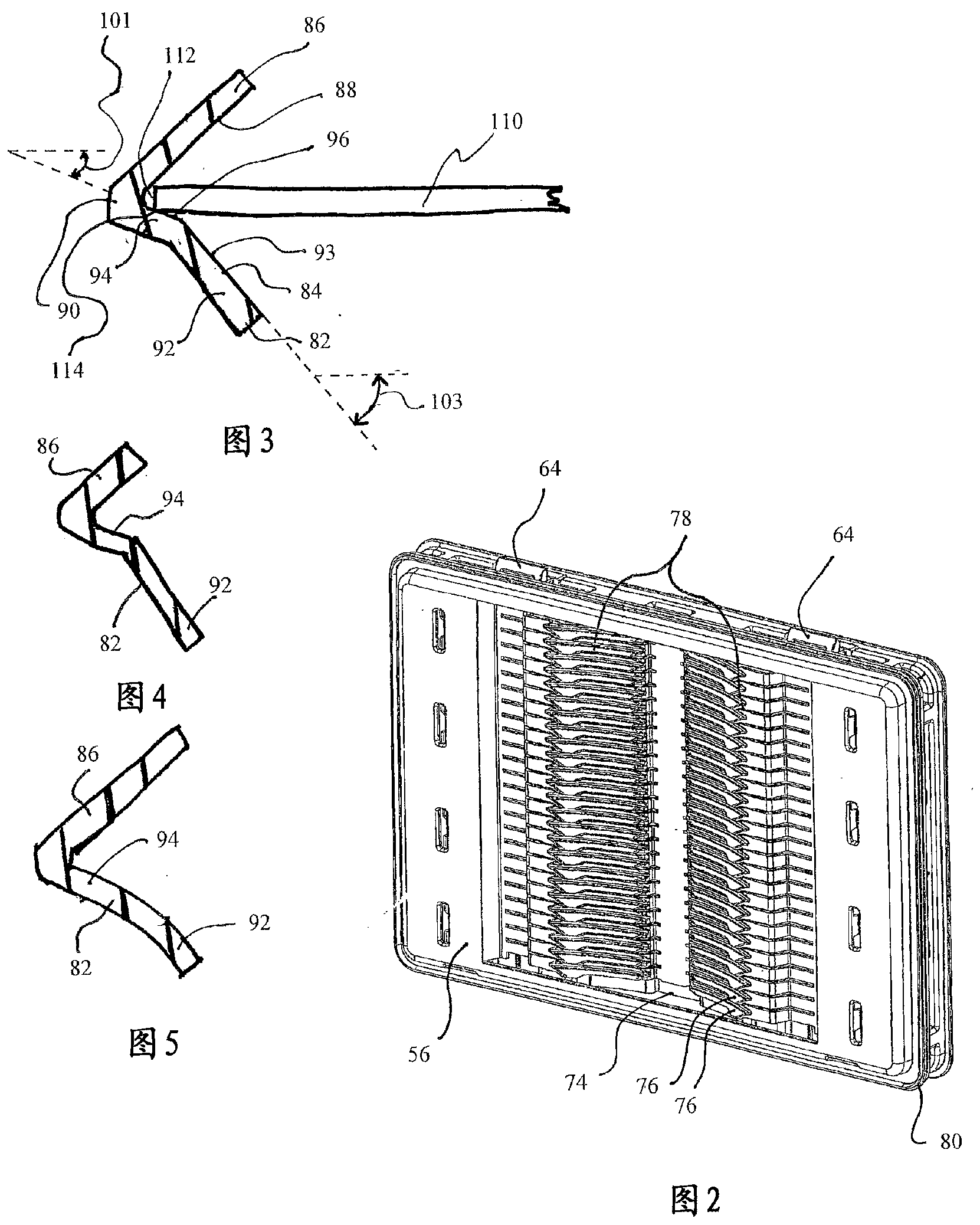

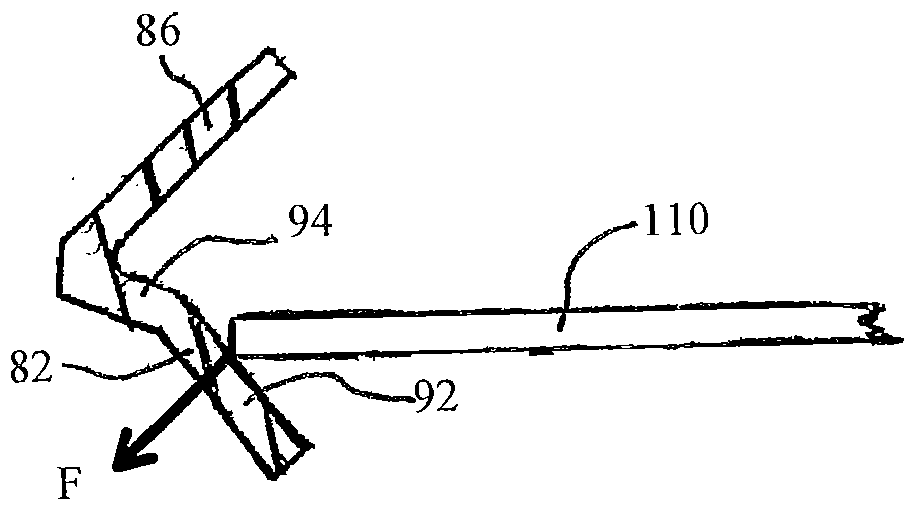

[0036] A recess 74 is centrally located on the inside of the door. Positioned within the recess is a plurality of wafer engaging portions 76 positioned to engage the vertically stacked spaced apart wafers positioned in the container portion 22 . The door has a seal or gasket 80 that engages and seals the door frame. The wafer engagement portion 76 includes a wafer cushion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com