Heat exchange plate

A heat exchange plate and unequal technology, which is applied in the field of heat exchange plates, can solve the problems of easy deformation, large area of heat exchange plates without grooves, insufficient overall strength and rigidity of heat exchange plates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

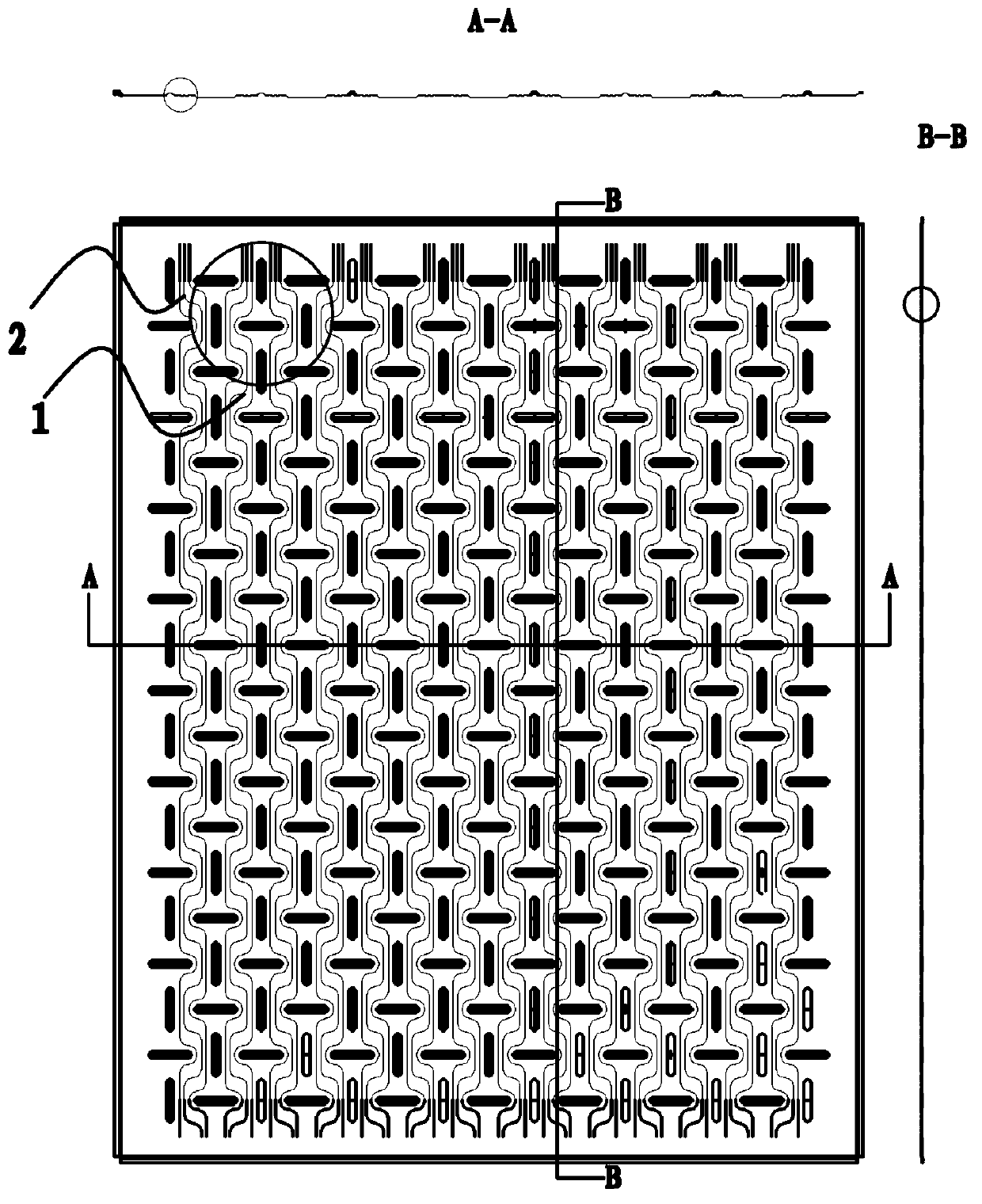

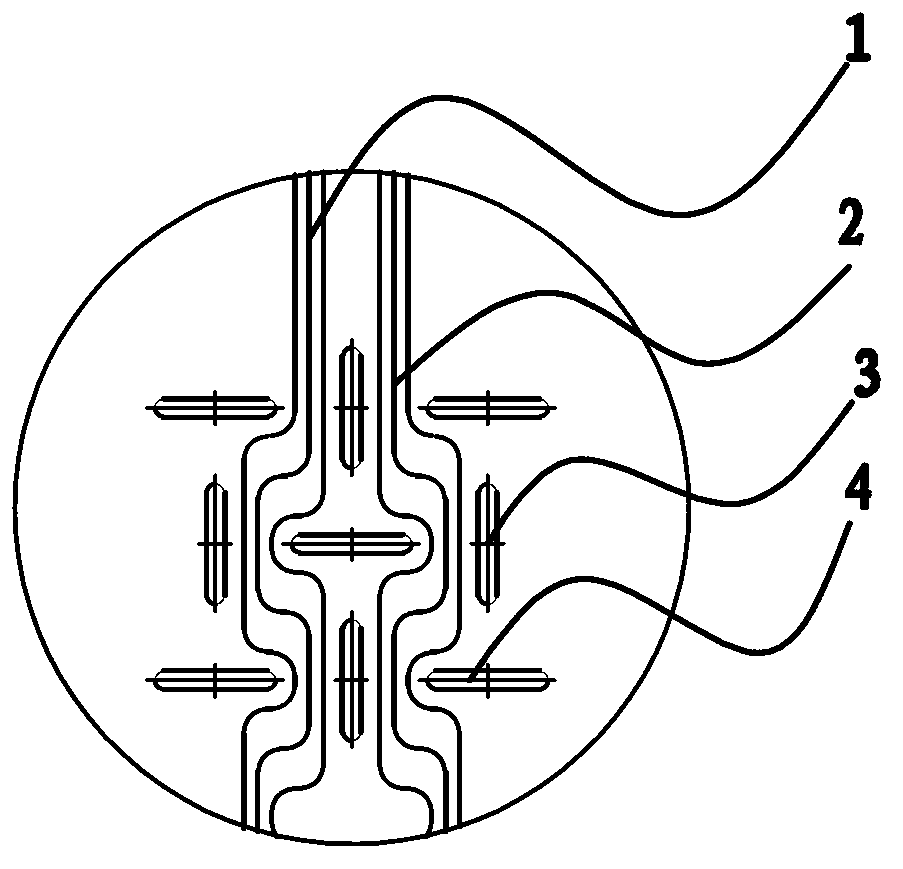

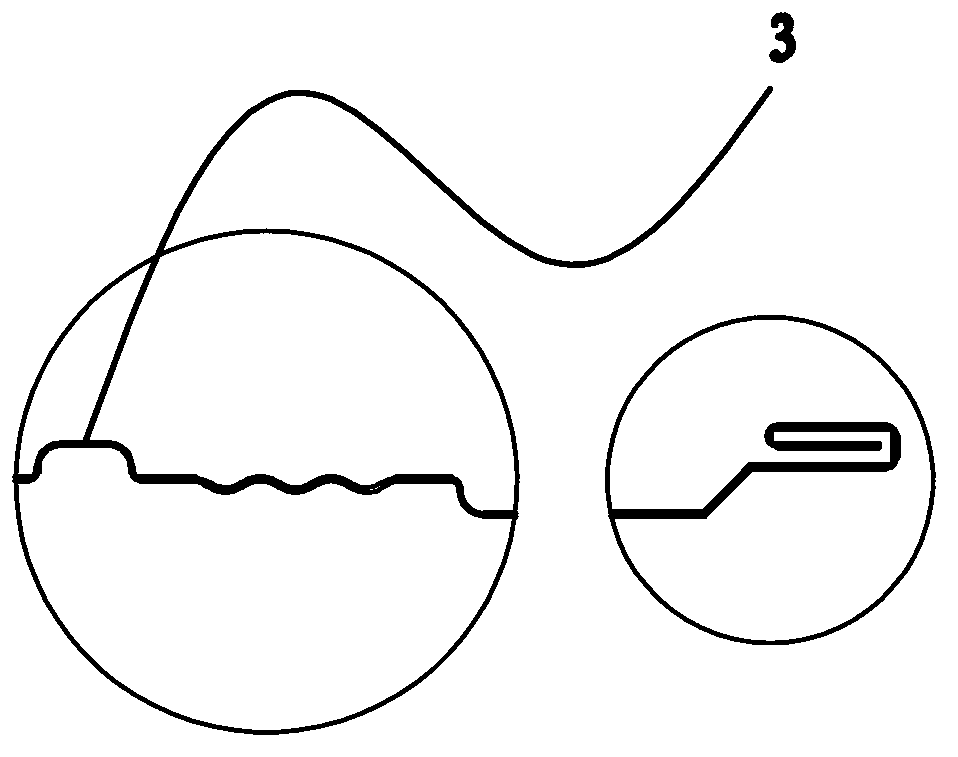

[0012] As shown in the figure, a heat exchange plate according to the present invention has concave and convex semicircular grooves 4, 3 and symmetrical serpentine-like unequal width grooves 1, 2 on the plate, which are cut into uniform size The aluminum sheet is formed by pressing and stretching through a mold once, and bending opposite sides twice. Concave and convex semicircular grooves and symmetrical serpentine unequal width grooves are realized by the stretching mechanism of the mold, and the depth can be realized by adjusting the mold according to the design requirements. The concave semicircular groove 4 and the convex semicircular groove 3 are long groove structures, which are perpendicular to each other and do not cross each other. It is also different. Its width is generally 2mm-5cm, and its depth is generally 1-10 times the thickness of the aluminum sheet. It is arranged symmetrically on both sides of the concave and convex semicircular grooves like a serpentine. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com