Fluidized bed drying process for ammonium sulfate

A technology of fluidized bed drying and ammonium sulfate, which is applied in the direction of drying solid materials, drying gas arrangement, heating to dry solid materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

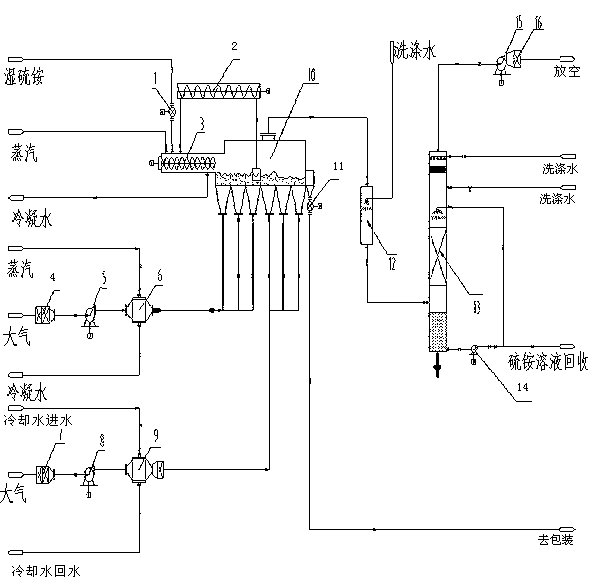

[0023] The formation of the fluidized bed drying system of the present invention is mainly: including star inlet valve 1. Mixed pre -dryer 3. Return equipment 2. Dorrhea cooler of fluidized bed 4. Dry air divorce filter 5. Dry air drumming fan 6. 6, Dry air heater 7, cold air dehogenetic filter 8, cold air drumor 9, freezing water cooler 10, star material outlet valve 11, wet spray washing device 12, washing tower 13, circulating pump 14, tail gas quotesFan 15, Tail Vitality Fiomer 16 and other equipment.

[0024] The device for mixed pre -drying 3 connects the star -type feed valve 1 and the return device 2. In this device, the wet material and drying materials are mixed., To achieve the purpose of mixing, pre -drying, and "thinning" material blocking of wet sulfate materials in the system, which can ensure the stable performance of wet sulfate material in the dried bed dryer 4, which can reduce or avoid fluidized bed operations due to imported materials due to imported materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com