Electroplating post-treatment apparatus

A post-processing device and processing tank technology, which is applied in the field of special processing devices, can solve the problems of electroplating working liquid harmful to human body, low production efficiency, and great risk to the health of production personnel, so as to speed up production automation, improve production efficiency, The effect of risk reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the drawings.

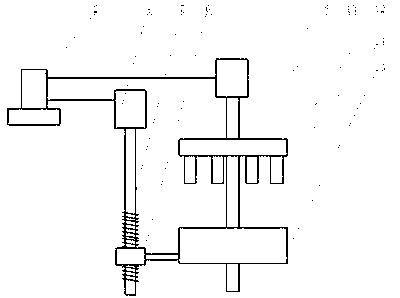

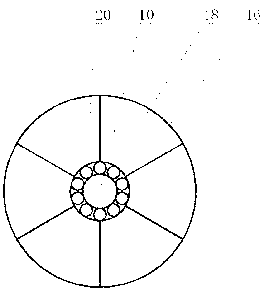

[0015] Such as figure 1 with figure 2 As shown, the present invention provides an electroplating post-processing device including a processing tank 16 connected with a lifting device, and a clamp body 12 arranged above the processing tank 16 and connected with an intermittently rotatable rotating device. The processing tank 16 is The circular ring shape is divided into a plurality of processing sub-slots 18 along the circumferential direction, and at least one clamp 14 is eccentrically arranged under the clamp body 12.

[0016] Fix the workpiece to be processed on the fixture 14, the lifting device drives the entire processing tank 16 to rise, so that the workpiece is immersed in the processing liquid contained in one of the processing sub-tanks 18 for electroplating post-processing. After the processing is completed, the lifting device drives the processing tank When 16 des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com