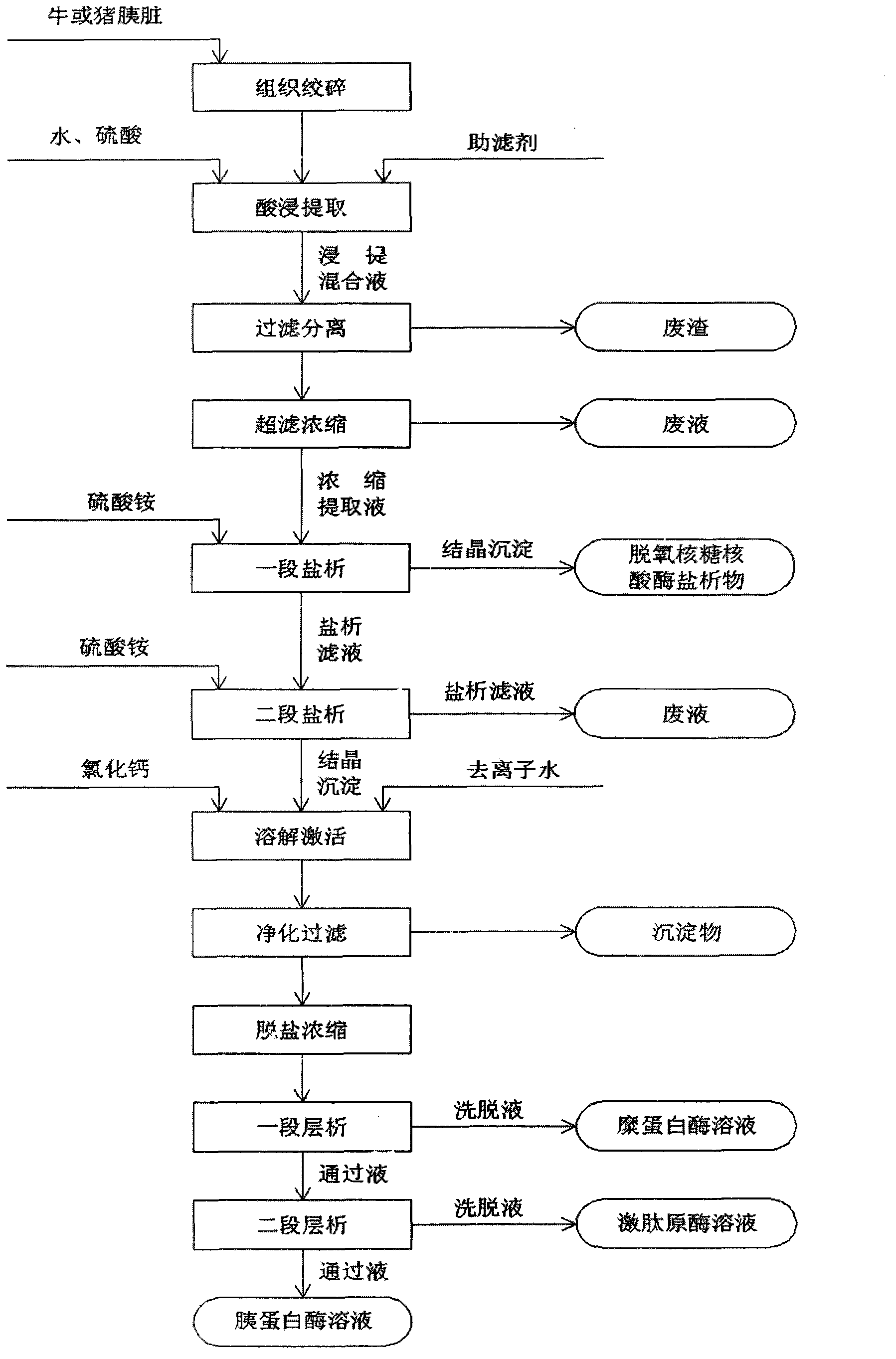

Production process for extracting four enzymes from cattle or pig pancreas

A production process and technology for porcine pancreas, applied in the field of bioengineering, can solve the problem of low comprehensive utilization rate of pancreas, and achieve the effects of high comprehensive utilization rate of pancreas, high activity and recovery rate, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: a kind of production technique that extracts four kinds of enzymes from bovine pancreas, it comprises the steps:

[0030] (1) Tissue mincing: remove the fat and connective tissue from the bovine pancreas, wash it with water, and mince it with a meat grinder;

[0031] (2) Acid leaching extraction: add water and sulfuric acid solution to the minced pancreas, the solid-to-liquid weight ratio is 1:4, the pH value is 2.6, stir and extract at room temperature for 15 hours to obtain an extraction mixture;

[0032] (3) Filtration and separation: first filter the extraction mixture with a drum sieve, then add perlite with 17% of the weight of bovine pancreas and stir, then use a plate and frame filter to filter and separate, collect the extraction filtrate, and discard the solid waste residue;

[0033] (4) ultrafiltration concentration: the extraction filtrate is filtered with a two-stage ultrafiltration membrane, and the ultrafiltration membrane with a molecular w...

Embodiment 2

[0043] Embodiment 2: a kind of production technique that extracts four kinds of enzymes from bovine pancreas, it comprises the steps:

[0044] (1) Tissue mincing: remove the fat and connective tissue from the bovine pancreas, wash it with water, and mince it with a meat grinder;

[0045] (2) Acid leaching extraction: add water and sulfuric acid solution to the minced pancreas, the solid-to-liquid weight ratio is 1:3, the pH value is 2.8, stir and extract at room temperature for 14 hours to obtain an extraction mixture;

[0046] (3) Filtration and separation: first filter the extraction mixture with a drum sieve, then add perlite with 16% bovine pancreas weight and stir, then use a plate and frame filter to filter and separate, collect the extraction filtrate, and discard the solid waste residue;

[0047] (4) ultrafiltration concentration: the extraction filtrate is filtered with a two-stage ultrafiltration membrane, and the ultrafiltration membrane with a molecular weight of 2...

Embodiment 3

[0057] Embodiment 3: a kind of production technique that extracts four kinds of enzymes from pig pancreas, it comprises the steps:

[0058] (1) Minced tissue: Remove fat and connective tissue from pig pancreas, wash it with water, and mince it with a meat grinder;

[0059] (2) Acid leaching extraction: add water and sulfuric acid solution to the minced pancreas, the solid-to-liquid weight ratio is 1:5, the pH value is 2.4, stir and extract at room temperature for 16 hours to obtain an extraction mixture;

[0060] (3) Filtration and separation: firstly, the leaching mixed solution is filtered with a drum sieve, then added with 18% perlite of porcine pancreas weight and stirred, and then filtered and separated by a plate-and-frame filter, the extraction filtrate is collected, and the solid waste residue is discarded;

[0061] (4) ultrafiltration concentration: the extraction filtrate is filtered with a two-stage ultrafiltration membrane, and the ultrafiltration membrane with a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com