Lift truck for replacing or overhauling disconnecting switch

A technology of isolating switches and lifting vehicles, which is applied to portable lifting devices, hoisting devices, etc., can solve the problems of muscle strain, difficulty in maintenance work, and danger-prone problems of the staff, so as to save physical strength, improve reliability, and improve replacement. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

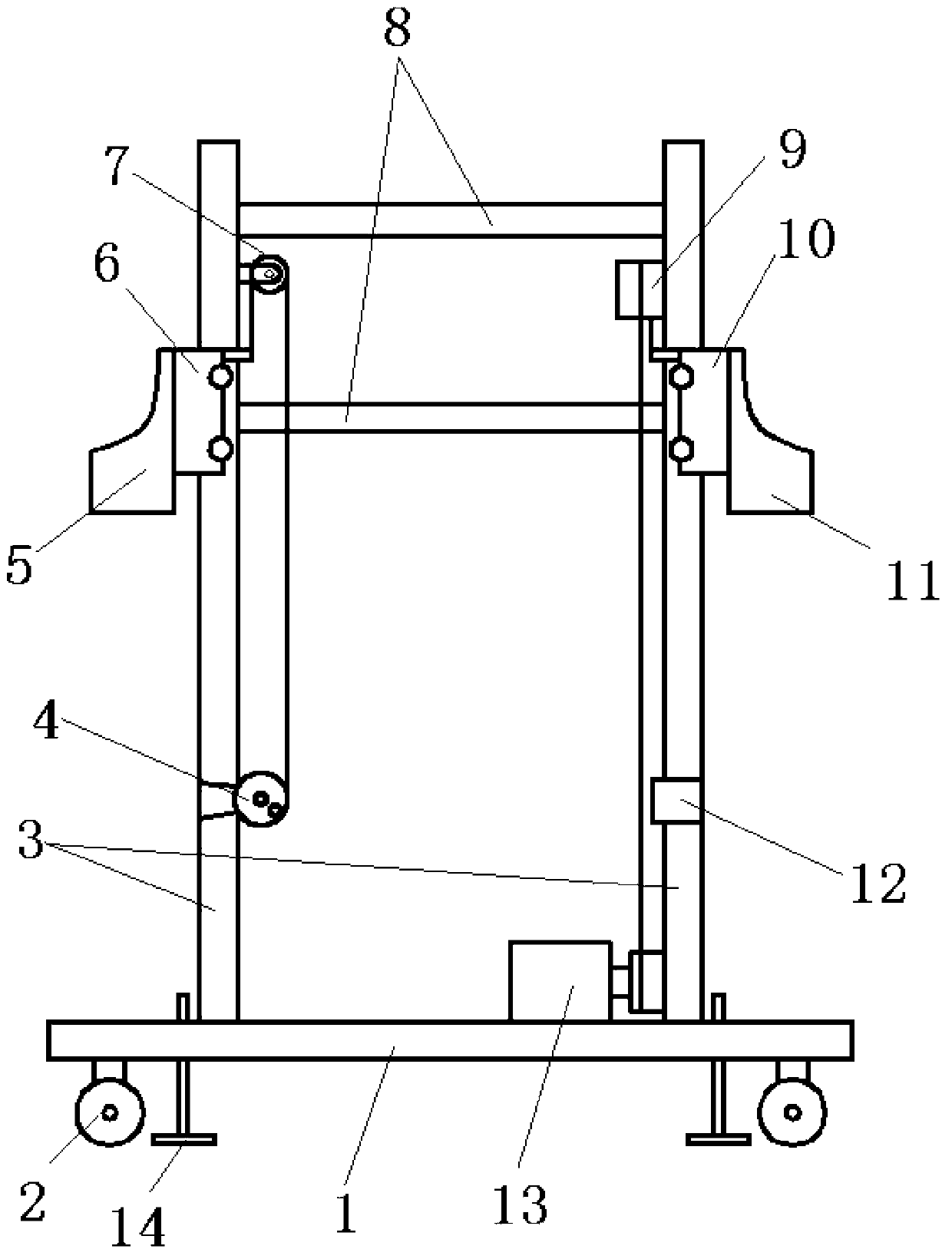

[0013] This embodiment provides an isolating switch replacement and overhaul lifting vehicle, which is characterized in that: the isolating switch replacement and overhauling lifting vehicle includes a base 1, casters 2, uprights 3, hand wheels 4, a left transport seat 5, and a left pulley 6. Left pulley 7, beam 8, right pulley 9, right trolley 10, right transport seat 11, limit plate 12, hoist 13;

[0014] Among them: the caster 2 is installed on the lower part of the base 1, the two uprights 3 are installed on the left and right sides above the base 1, the hand wheel 4 is installed on the lower part of the left upright 3, the left pulley 7 is installed on the upper part of the left upright 3, and the left transport seat 5 It is fixedly connected with the left block 6, and the left block 6 is installed on the left column 3, and the wire rope goes around the left pulley 7 to connect the hand wheel 4 and the left block 6; the winch 13 is installed on the right side of the upper ...

Embodiment 2

[0018] This embodiment provides an isolating switch replacement and overhaul lifting vehicle, which is characterized in that: the isolating switch replacement and overhauling lifting vehicle includes a base 1, casters 2, uprights 3, hand wheels 4, a left transport seat 5, and a left pulley 6. Left pulley 7, beam 8, right pulley 9, right trolley 10, right transport seat 11, limit plate 12, hoist 13;

[0019] Among them: the caster 2 is installed on the lower part of the base 1, the two uprights 3 are installed on the left and right sides above the base 1, the hand wheel 4 is installed on the lower part of the left upright 3, the left pulley 7 is installed on the upper part of the left upright 3, and the left transport seat 5 It is fixedly connected with the left block 6, and the left block 6 is installed on the left column 3, and the wire rope goes around the left pulley 7 to connect the hand wheel 4 and the left block 6; the winch 13 is installed on the right side of the upper ...

Embodiment 3

[0022] This embodiment provides an isolating switch replacement and overhaul lifting vehicle, which is characterized in that: the isolating switch replacement and overhauling lifting vehicle includes a base 1, casters 2, uprights 3, hand wheels 4, a left transport seat 5, and a left pulley 6. Left pulley 7, beam 8, right pulley 9, right trolley 10, right transport seat 11, limit plate 12, hoist 13;

[0023] Among them: the caster 2 is installed on the lower part of the base 1, the two uprights 3 are installed on the left and right sides above the base 1, the hand wheel 4 is installed on the lower part of the left upright 3, the left pulley 7 is installed on the upper part of the left upright 3, and the left transport seat 5 It is fixedly connected with the left block 6, and the left block 6 is installed on the left column 3, and the wire rope goes around the left pulley 7 to connect the hand wheel 4 and the left block 6; the winch 13 is installed on the right side of the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com