Combined type multifunctional hanger

A multi-functional and combined technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of unable to meet the hoisting requirements of large and heavy industrial equipment, discounted hoisting height, and large span of hoisting points, etc., to eliminate potential safety hazards , The height space is small, the effect of increasing the hoisting height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

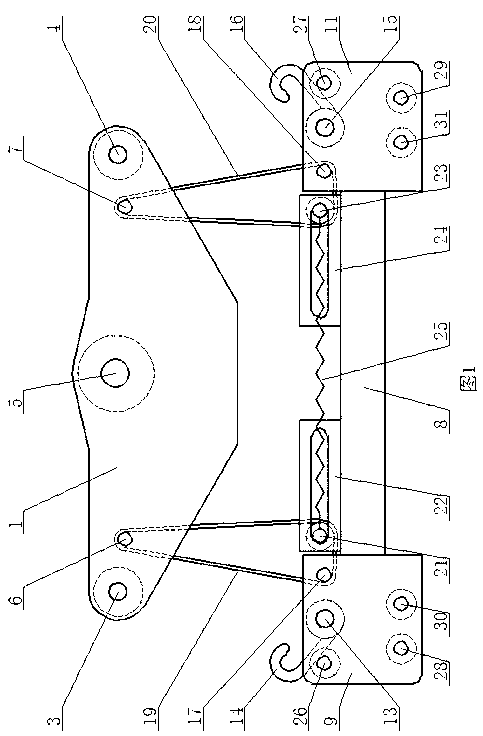

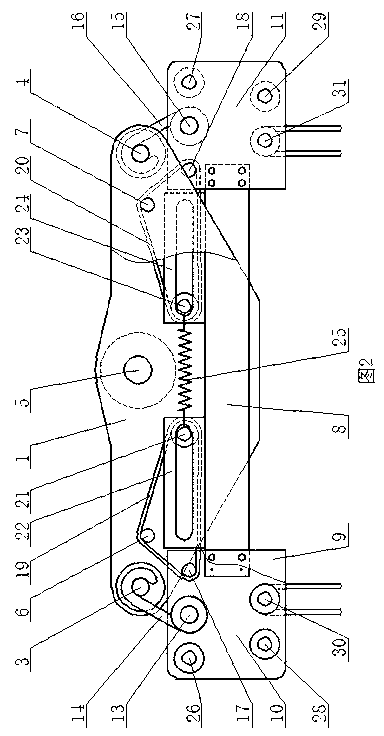

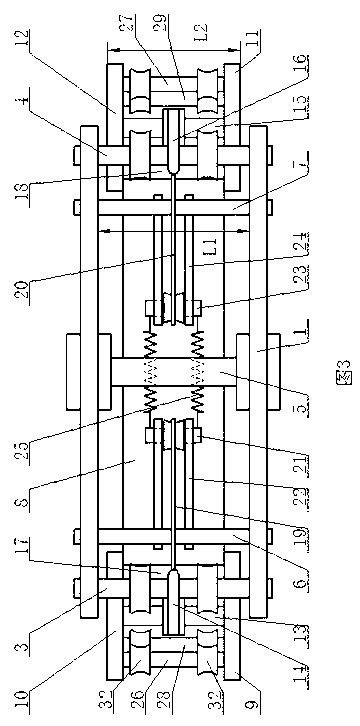

[0010] The combined multifunctional lifting device of the present invention comprises a double-plate balance beam 1 composed of two parallel balance plates, a supporting balance beam is arranged below the double-plate balance beam 1, and the two balance plates of the double-plate balance beam 1 The first hoisting shaft 3, the second hoisting shaft 4, the hoisting shaft 5, the first limit shaft 6 and the second limit shaft 7 are installed between them, the first hoisting shaft 3 and the second hoisting shaft 4 are located on the two sides of the double-plate balance beam 1 end, the lifting shaft 5 is located in the middle of the double-plate balance beam 1, the first limit shaft 6 and the second limit shaft 7 are located on both sides of the lifting shaft 5, the supporting balance beam includes a beam 8, and the first support plate 9 is installed on one end of the beam 8 And the second support plate 10, the third support plate 11 and the fourth support plate 12 are installed at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com