Fuse with sleeve structure and mounting method

A fuse and bushing technology, applied in the direction of electrical component structure associations, emergency protection devices, electrical components, etc., can solve the problems of transformer oil leakage and easy live operation, so as to reduce the risk of insulating oil leakage and improve the safety of use. Sex, volume reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

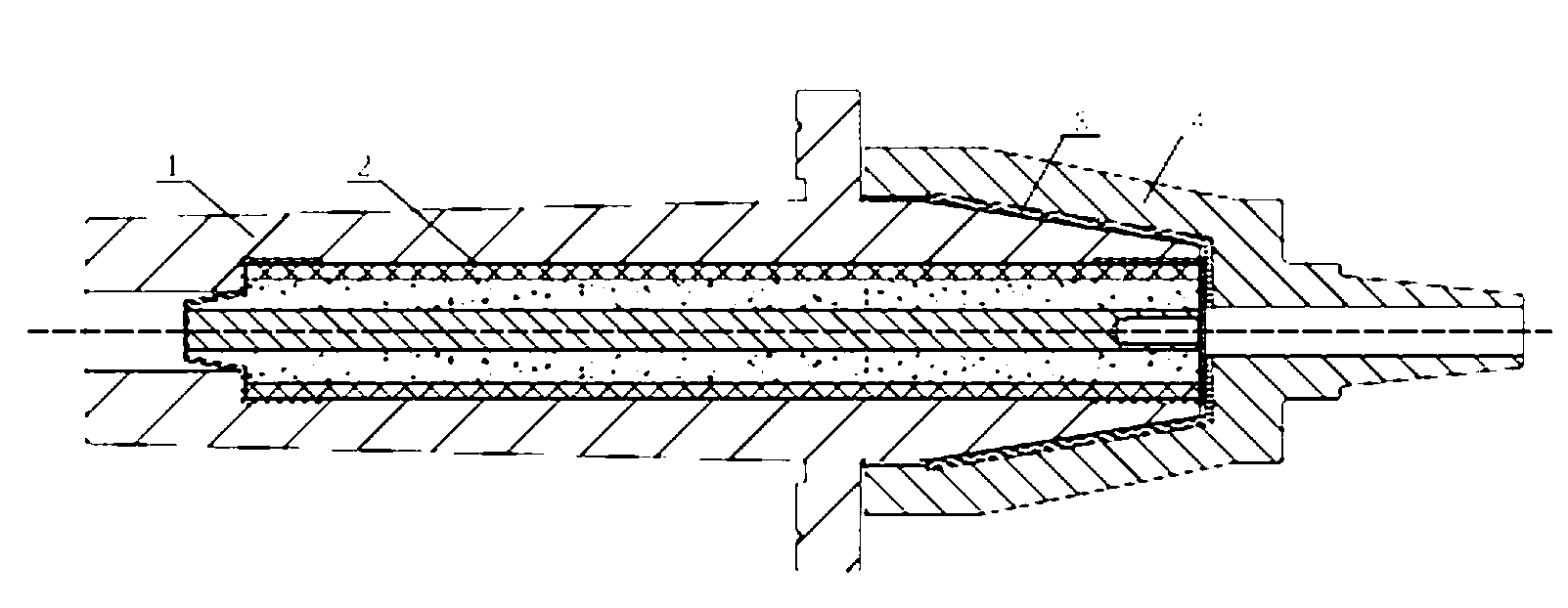

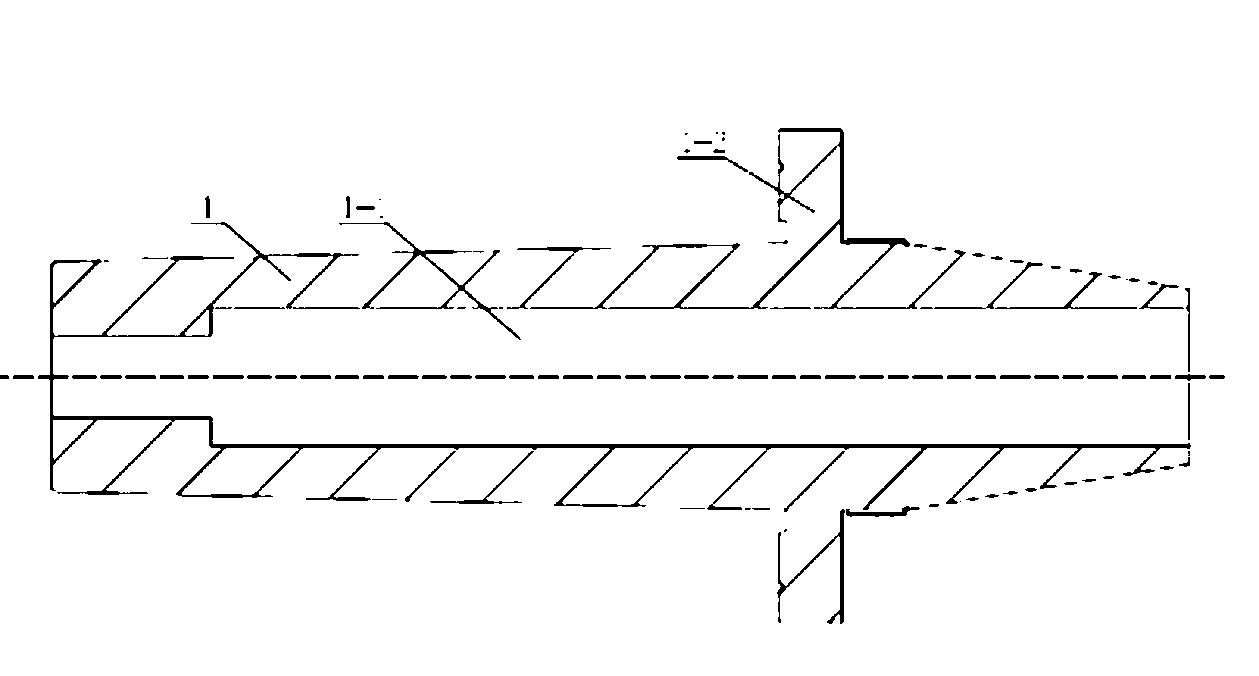

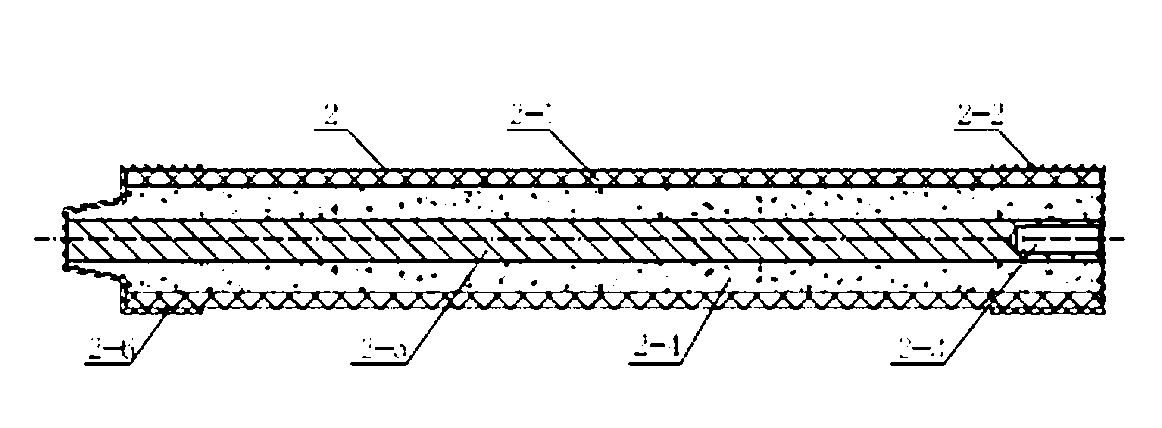

[0023] as attached Figures 1 to 7 As shown, a fuse with sleeve structure in this embodiment, the fuse 2 includes a fuse outer layer 2-1, quartz sand 2-4, a fuse conductor 2-5, and winding connection ends at both ends of the fuse Metal guide block 2-6 and cable connection end metal guide block 2-2. Quartz sand 2-4 is arranged between the fuse conductor 2-5 and the outer layer of the fuse 2-1, and the metal guide block 2-6 at the winding connection end and the metal guide block 2-2 at the cable connection end are respectively fixed on the outer layer of the fuse 2-1, the fuse 2 forms a closed structure. It also includes a sleeve, and the sleeve includes an inner sleeve 1 , an outer sleeve 4 and an inner protection sleeve 3 of the sleeve. The inner sleeve 1 is provided with a fuse insertion hole 1-1, the size of the inner wall of the fuse insertion hole 1-1 corresponds to the size of the outer wall of the fuse 2, and the two can be interference fit after the fuse 2 is inserted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com