Engine crankshaft composite shock absorber

An engine and shock absorber technology, applied in elastic shock absorbers and other directions, can solve the problem of incapable of compound vibration and vibration reduction, and achieve the effects of reducing bending and torsional amplitudes, improving NVH and ride comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

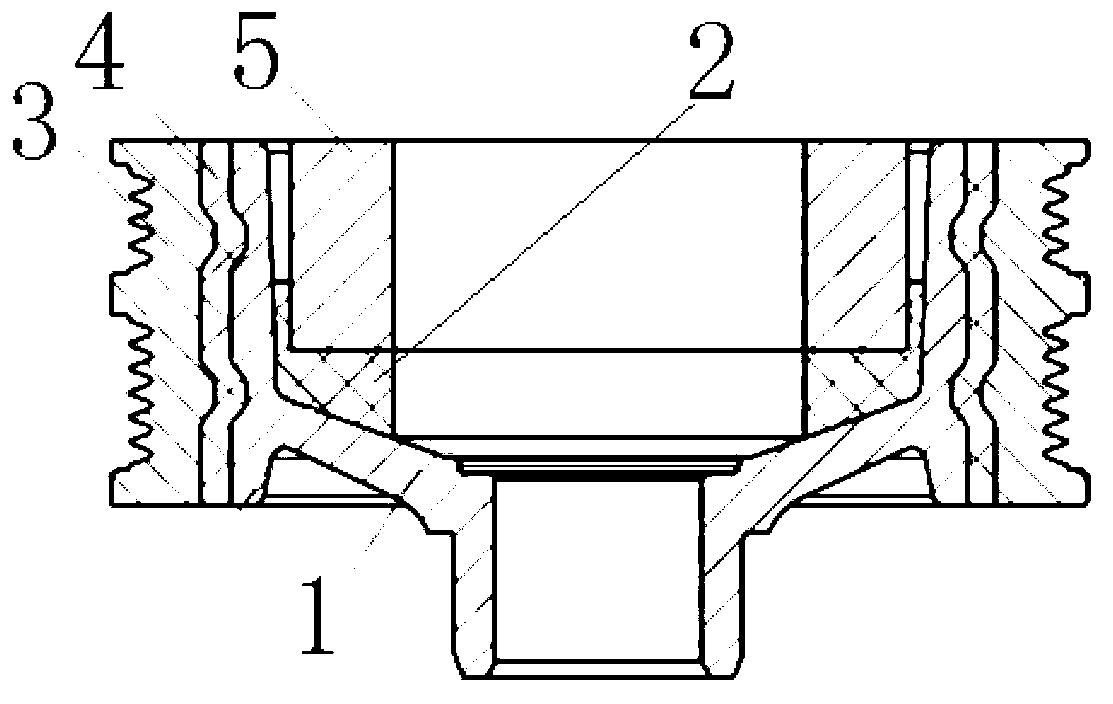

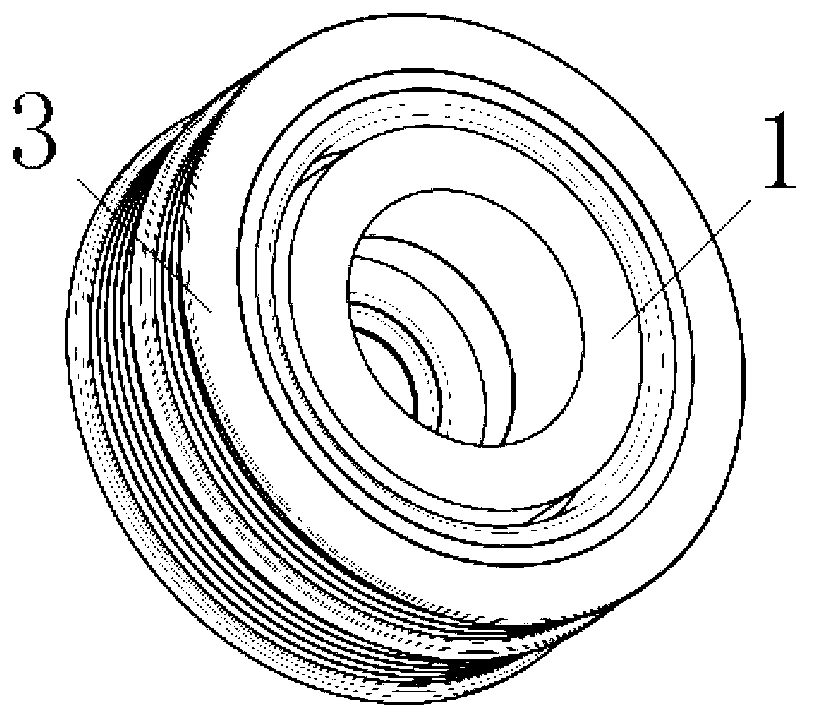

[0016] like figure 1 and figure 2 As shown, a compound damper for an engine crankshaft, which combines a torsional damping unit and a bending damping unit, so that the entire engine crankshaft can The bending and torsional amplitudes are simultaneously reduced. The bending damping unit is arranged on the inner circumference of the hub 1, and the torsional damping unit is arranged on the outer circumference of the hub 1. The hub 1 is connected to the end of the crankshaft of the engine by bolts.

[0017] Wherein, the bending damping unit includes an inertia ring 5 and a rubber ring 2, and the rubber ring 2 is arranged between the wheel hub 1 and the inertia ring 5, that is, the inertia ring and the wheel hub are fixed together by rubber ring vulcanization.

[0018] The torsional vibration dam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com