A gas extraction method

A technology of gas drainage and casing, which is applied in the direction of gas discharge, drilling equipment and methods, mining fluids, etc., can solve the problems of heavy drilling workload and achieve the effect of solving blind areas of drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

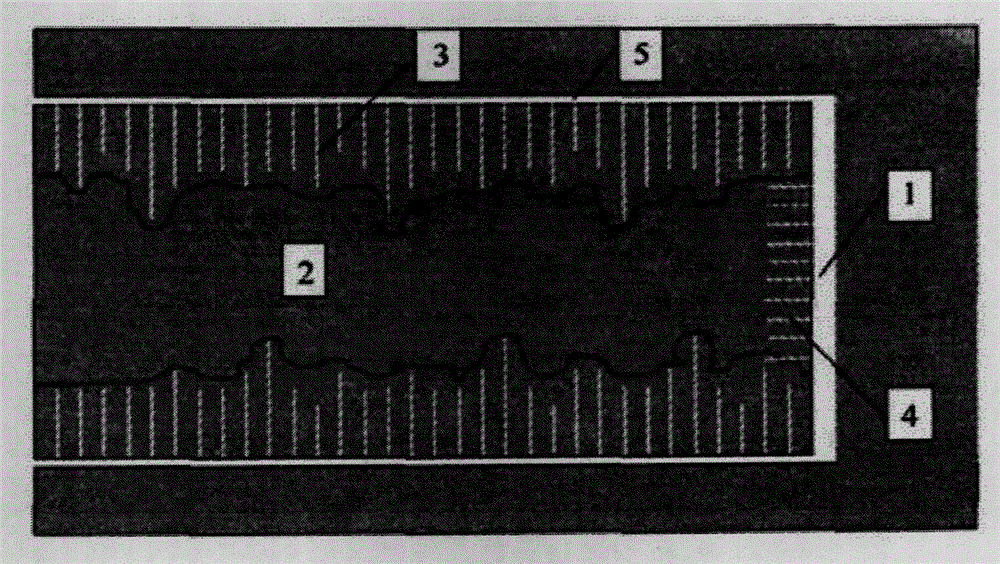

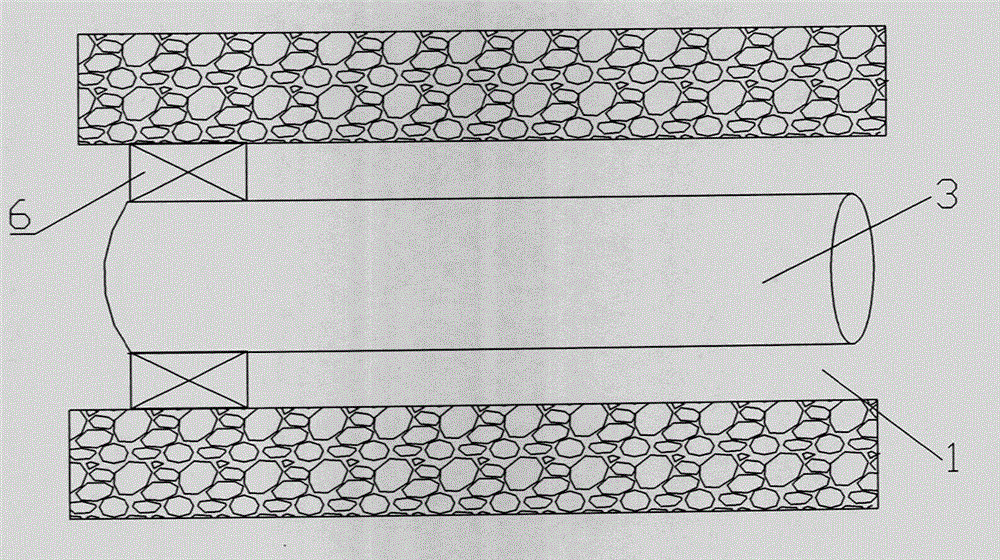

[0025] Please refer to Figure 2 to Figure 4 , the gas extraction method in the present invention, particularly, provides a kind of gas extraction method that can be used in soft coal seam deep hole and large aperture, and this method comprises the following steps:

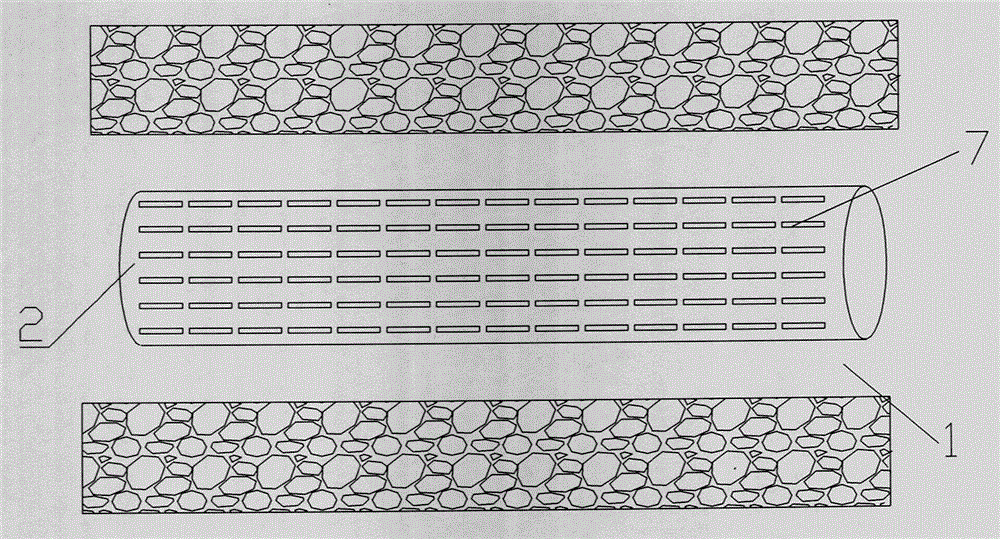

[0026] Step 1, please refer to figure 2 Utilize the drilling rig to form the borehole 1, first adopt the first sleeve pipe 2 in the drilling process of the drilling rig, and stop drilling when the depth of the borehole 1 reaches 15-25 meters from the design depth; wherein, the first sleeve pipe 2 Air holes 7 are arranged on the pipe wall; preferably, the drilling rig uses a reverse circulation down-the-hole hammer as the drilling system, and of course other methods can also be used fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com