Full automatic wood processor

A processing machine, fully automatic technology, applied in the direction of wood processing equipment, manufacturing tools, etc., can solve the problems of process dispersion, poor precision, low efficiency, etc., to achieve the effect of ensuring processing accuracy and reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

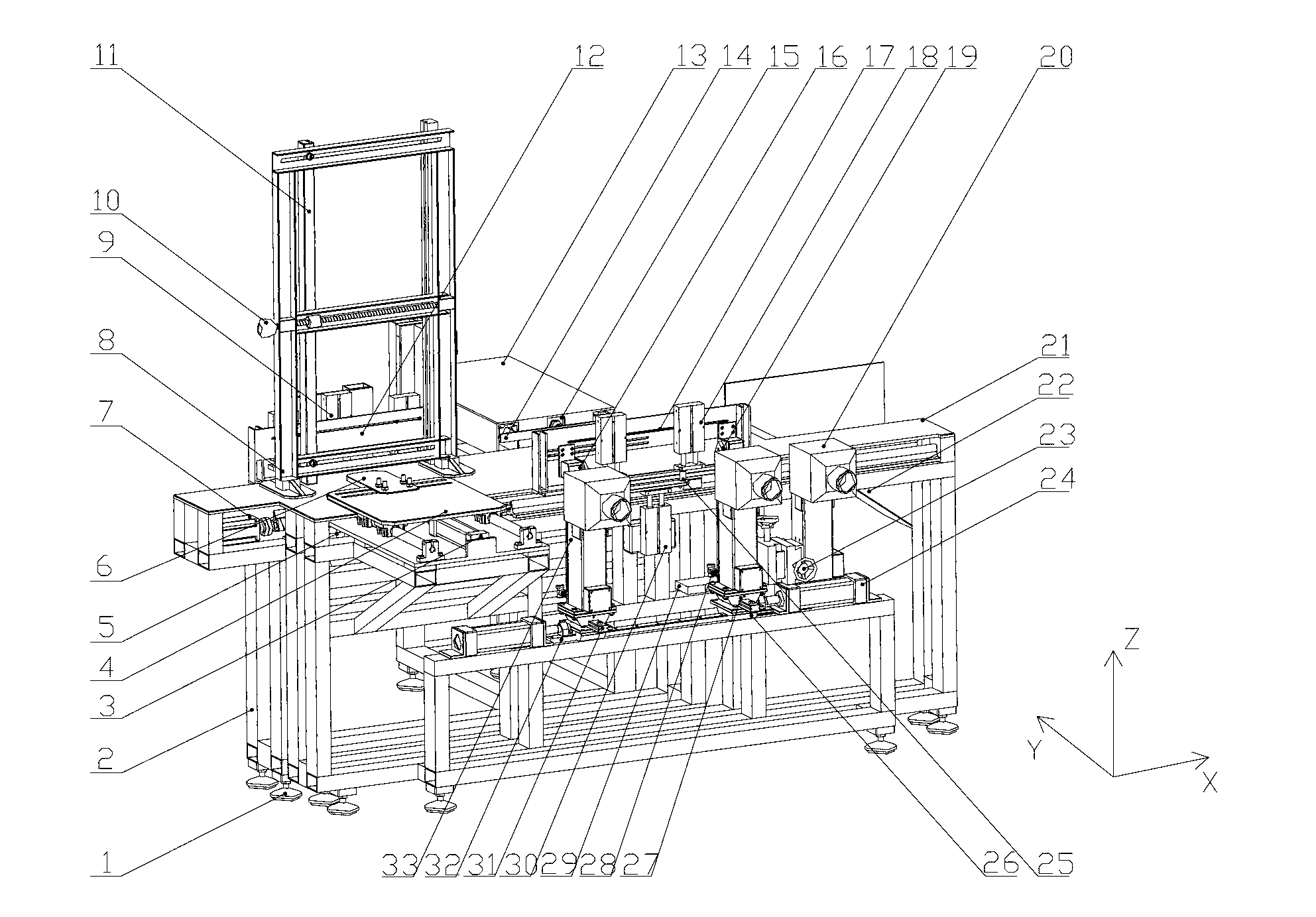

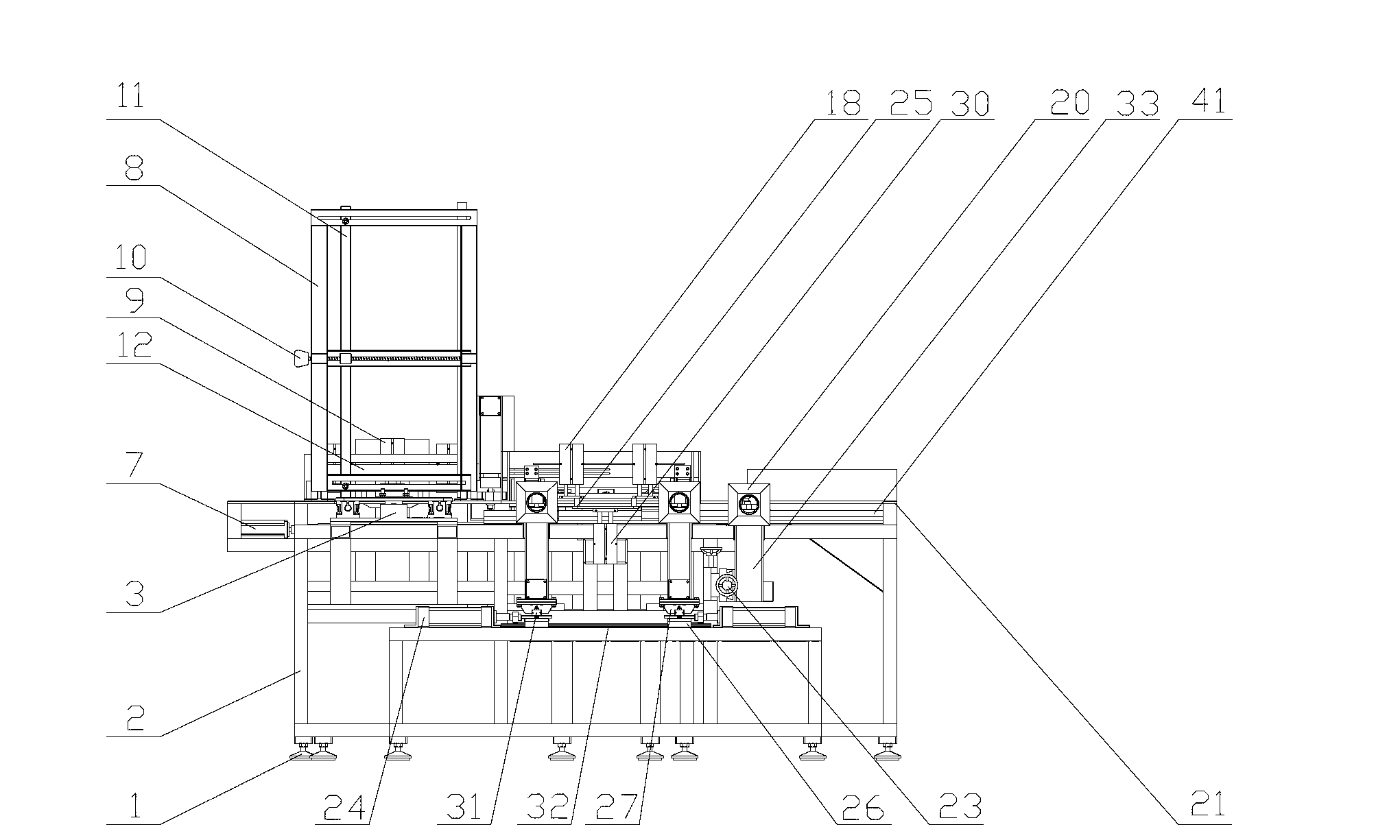

[0031] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

[0032] see Figure 2-9 , the embodiment of the present invention is provided with base 1, bracket 2, fixed platform 21, XIYI screw guide rail module, XII cylinder linear guide rail module, blanking module, pushing module, positioning module, profiling processing module, cutting module and corresponding electrical components.

[0033] The XⅠYⅠ screw guide module is composed of the XⅠ-axis screw guide module and the YⅠ-axis screw guide module. The slider XⅠ44 in the XⅠ-axis screw module is installed on the guide rail XⅠ35, and the servo motor XⅠ7 drives the rotation of the screw XⅠ37 to drive the movement Platform XI40; the slider YI45 and the accompanying fixture I12 in the YI-axis screw guide module are installed on the guide rail YI36, and the servo motor YI39 drives the screw YI38 to rotate to drive the mobile platform YI;

[0034] The accompanyin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com