A general hydraulic station energy saving method

A technology of hydraulic station and hydraulic energy storage, which is applied in the direction of fluid pressure actuation device, fluid pressure actuation system components, mechanical equipment, etc., and can solve the problems of low reliability and safety, small scope of application, limited scope of use, etc. problems, to achieve the effect of improving system reliability and maintainability, high security redundancy, and broadening the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The utility model is described in further detail below in conjunction with the accompanying drawings.

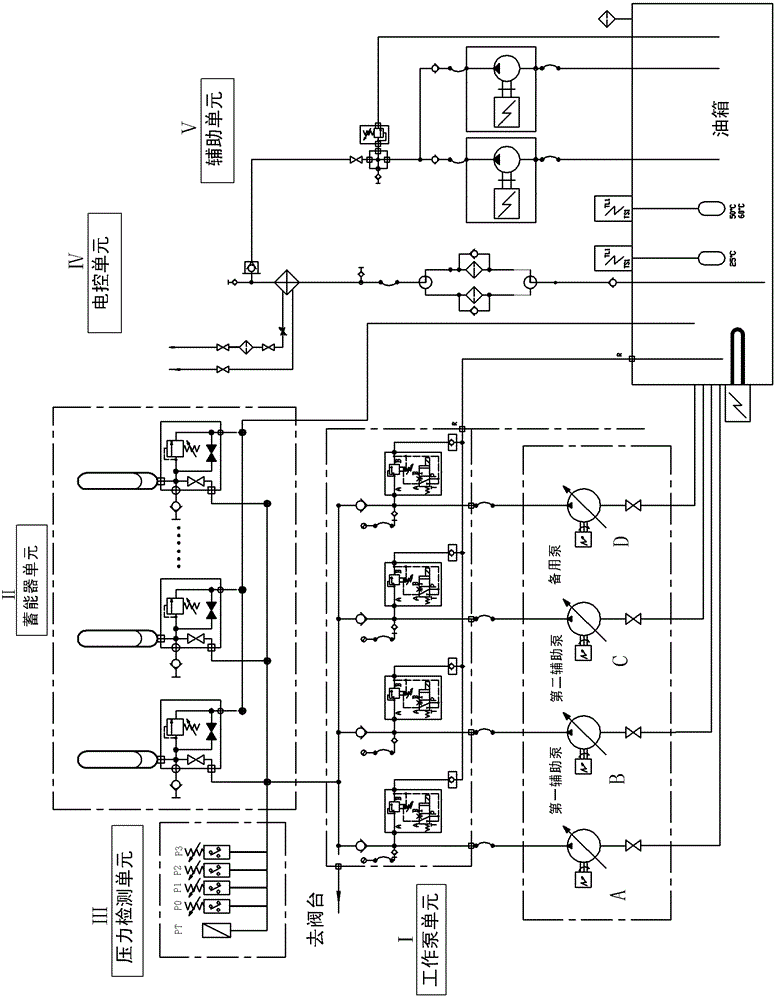

[0039] like figure 1 Shown is a preferred embodiment of the present invention.

[0040] A general energy-saving method for a hydraulic station, including a working pump I, a hydraulic energy storage station II, a pressure detection unit III, and an electric control unit IV; And the hydraulic energy storage station II provides the main flow and pressure and the flow required to maintain the internal and external leakage of the system. Among them, the main pump is in normal operation, and the auxiliary pump is controlled by the signal detected by the pressure detection unit III and controlled by the electronic control unit IV.

[0041] The system electronic control unit IV is the same as every hydraulic station now, the electronic control unit is essential, the start and stop of the driving motor and the loading or unloading of the pump are all realized by its software...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com