An anti-crack groove provided on a wallboard, a mold frame for making the anti-crack groove, and an installation method for a wallboard provided with the anti-crack groove

An installation method and technology of anti-crack tape, applied in the field preparation of building components, processing of formwork/formwork/work frame, building materials, etc., can solve the problem of durable bonding of wall panels and wall Loss of aesthetics, separation of anti-crack strips and wall panels, etc., to achieve the effect of simple manufacturing methods and construction methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

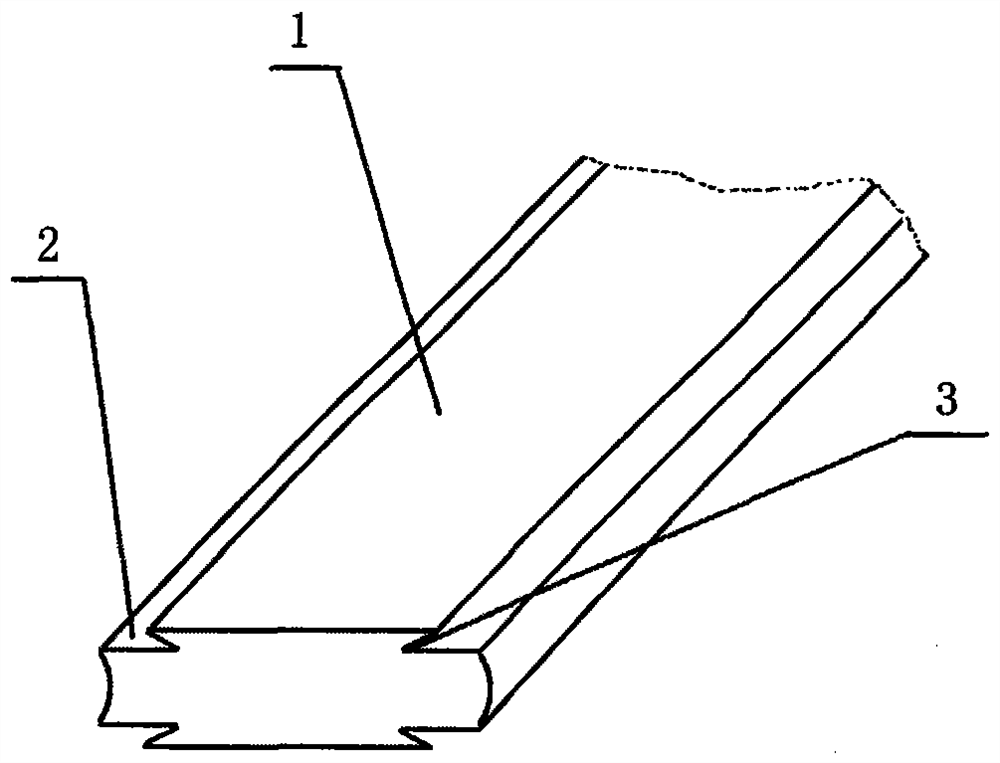

[0016] like figure 1 As shown, a crackboard tank is provided on the wall panel, characterized in that the anti-cleavage groove 2 is a gap provided on each edge of the wall panel surface 1, the inner angle 3 of the gap is less than 90 degrees, depth The thickness equivalent to the paste the split belt.

example 2

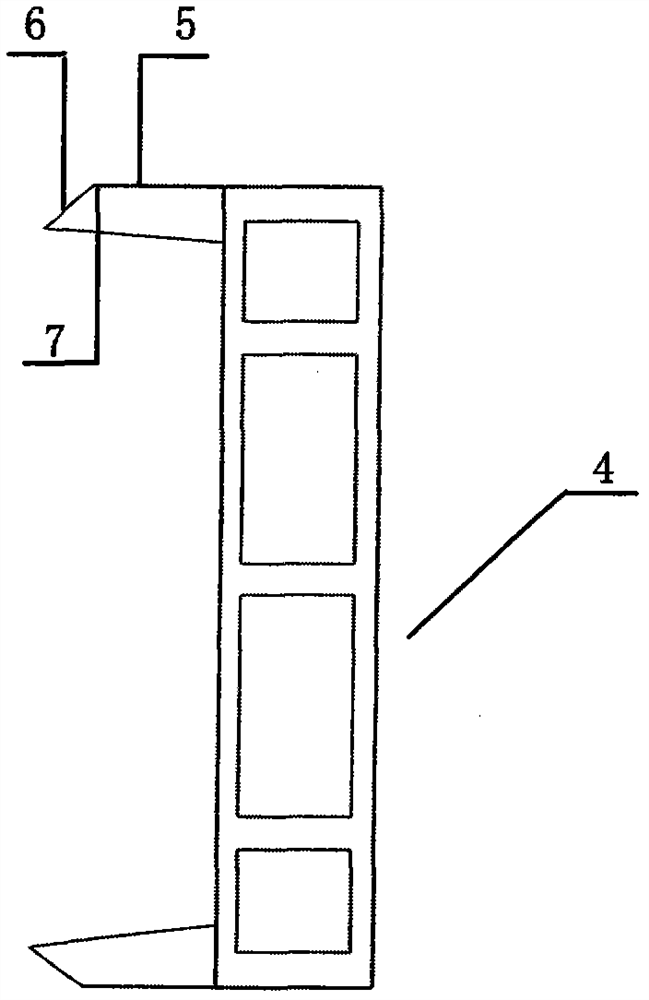

[0018] like figure 2 As shown, the mold frame for making the anti-strip groove is configured by the outer mold panel 4 of a wall panel, and the two quartrid cylinders 5 are connected to both sides of the same side of the template 4, respectively, and The other side faces a plane with the other side of the template 4, and is still shorter than the opposite side of the cylinder 5, and the inner angle 7 formed by the fourth surface 6 is greater than 90 degrees.

example 3

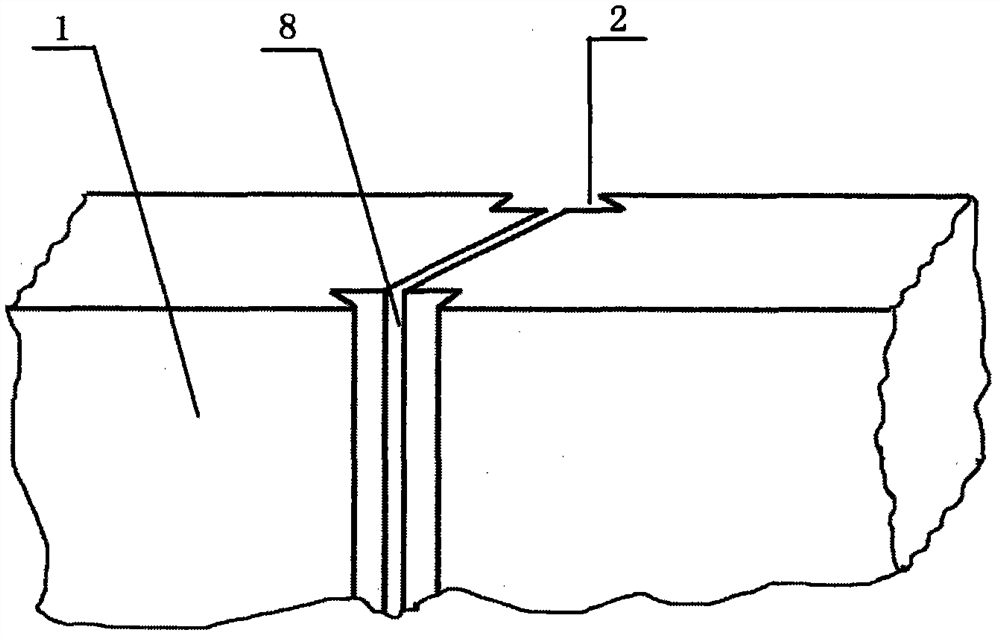

[0020] like image 3 As shown, the mounting method of the wall panel provided with the anti-decentral groove is to oppose the side of the adjacent two plates, and the filling gelation material of the placing material is filled, and then the correction is flat, and it is strict, so adjacent 1 of the two anti-crackboard grooves 2, forming a waist trapezoidal groove body 8, cleaning up floating dust at each angle in the groove body 8, and then hierarchical adhesive materials and paste anti-cracking With a strip or only a glue material, it is completely compact, requiring the width of the anti-crack strip, preferably greater than the width of the slot of the waist trapezoidal groove body 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com