System and method for controlling vibration feeding in speed stabilizing mode

A vibrating feeding and control system technology, applied in packaging automatic control, solid materials, packaging, etc., can solve problems such as difficulty in recruiting people, affecting profit margins, and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

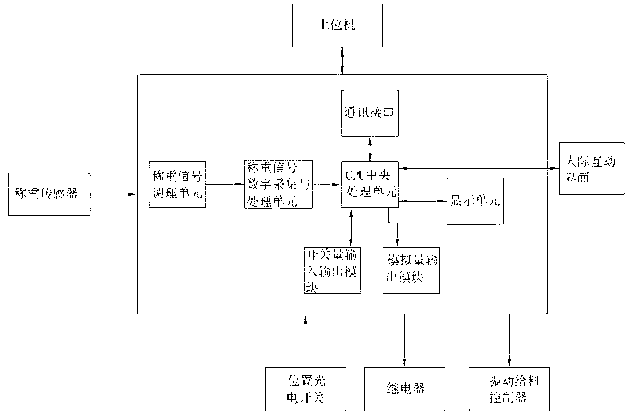

[0025] like figure 1 As shown, the vibrating feeding steady speed control system of the present invention includes a vibrating feeding mechanism and a weighing mechanism, and the system also includes:

[0026] A weighing sensor is used to obtain the weight signal of the current packaging material on the weighing mechanism; a weighing signal conditioning unit is used to condition the signal obtained from the weighing sensor and filter out the interference signal;

[0027] The weighing signal digital acquisition and processing unit is used to convert the signal conditioned by the weighing signal conditioning unit into a digital signal, and further upload it to the CPU central processing unit;

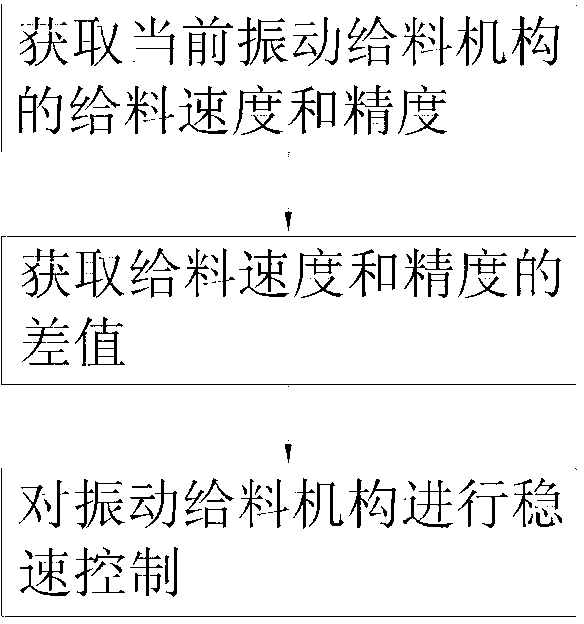

[0028] The CPU central processing unit is used to process the signal transmitted from the load cell and communicate with the peripheral host computer. By comparing the current feeding speed and accuracy with the originally set target feeding speed and accuracy, according to the comparison...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com