Self-propelled potato ridging and fertilizing planting machine

A technology of ridge fertilization and potato application in the direction of agricultural machinery and tools, shovels, plows, etc., which can solve the problems of time-consuming, low efficiency, and labor, and achieve the effects of increasing emergence rate, improving moisture conservation, and improving seeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

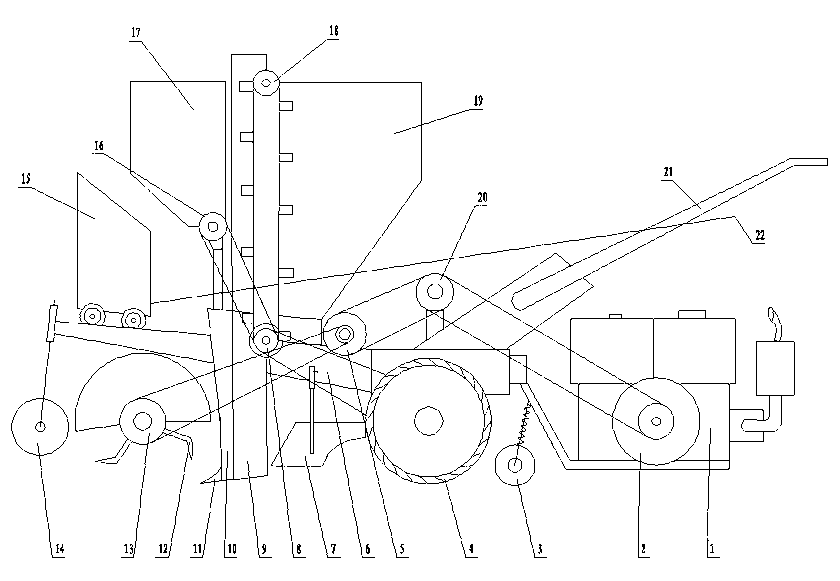

[0012] Such as figure 1 , 2 As shown, 1 diesel engine, 2 power output pulley, 3 suppressing wheel, 4 traveling wheel, 5 transition wheel, 6 frame, 7 ridging device, 8 double sprocket I, 9 seeding pipe, 10 fertilizing pipe, 11 Plow, 12 Rotary tillage device, 13 Rotary tillage device driving wheel, 14 Depth adjustment wheel, 15 Removable counterweight, 16 Fertilizing device driving wheel, 17 Fertilizer box, 18 Sowing device, 19 Seed box, 20 Distribution wheel, 21 Operating armrest, 22 counterweight push-pull rods, 23 driving sprockets.

[0013] The left side of the rack is the front end, and the right side is the rear end. A movable counterweight is installed on the upper part of the front end of the frame, and a depth adjustment wheel, a rotary tillage device, a fertilization pipe, a seeding pipe, a ridging device and a pressing wheel are installed on the lower part in sequence from front to back, and a diesel engine and an operating handrail are installed. on the rear of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com