Decompression chamber structure of a large flow balanced pressure regulating valve

A pressure regulating valve, balanced technology, applied in the direction of balance valve, safety valve, valve device, etc., can solve the problems affecting product quality and service life, unsuitable for low temperature environment, high requirements for bellows, to avoid easy wear and failure, The effect of low cost and few sealing links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

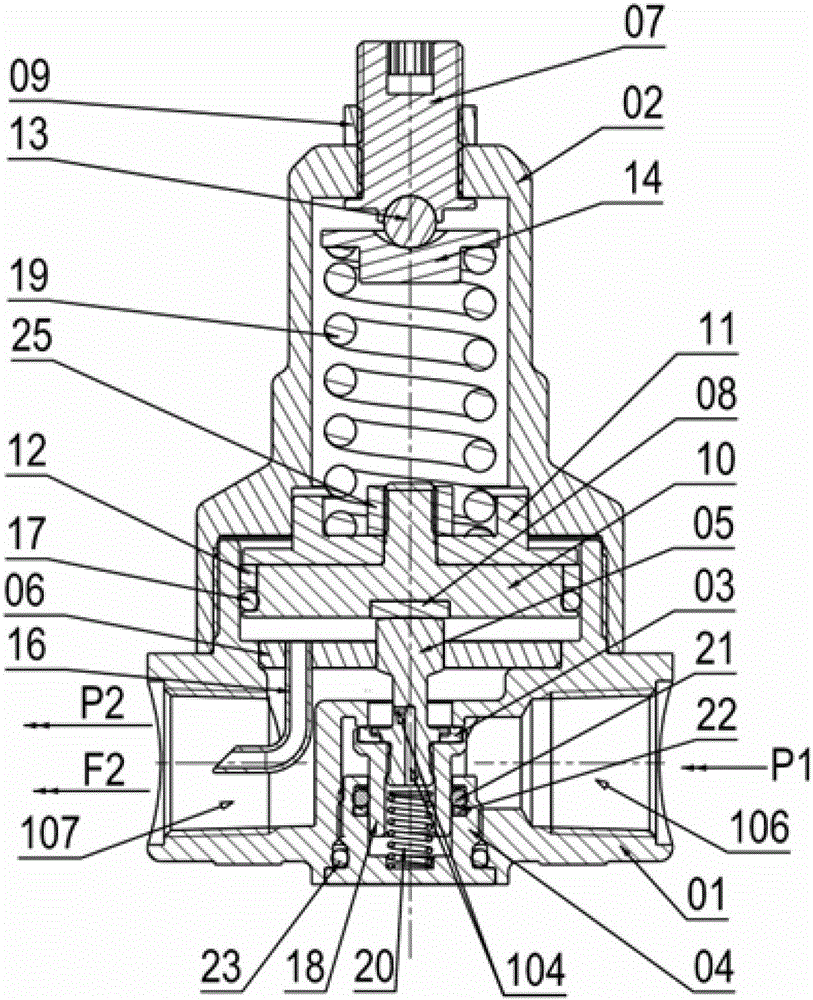

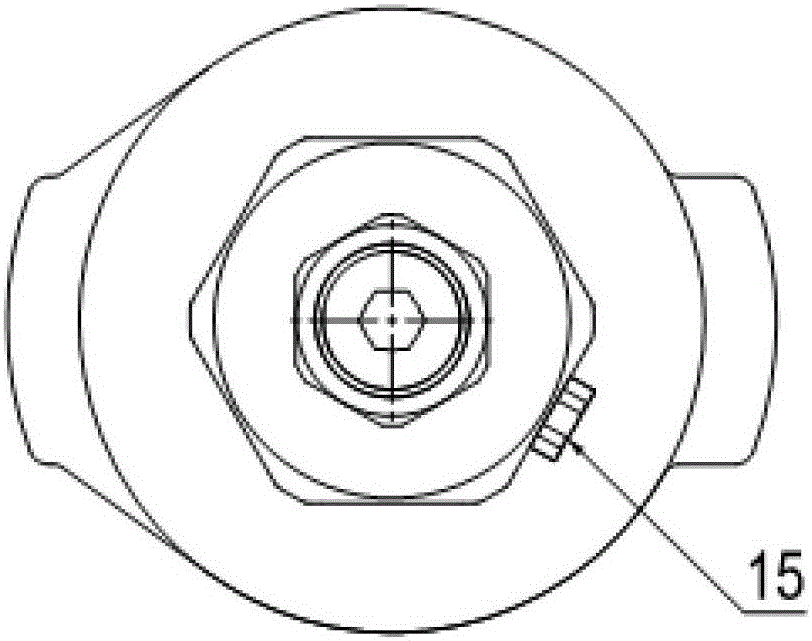

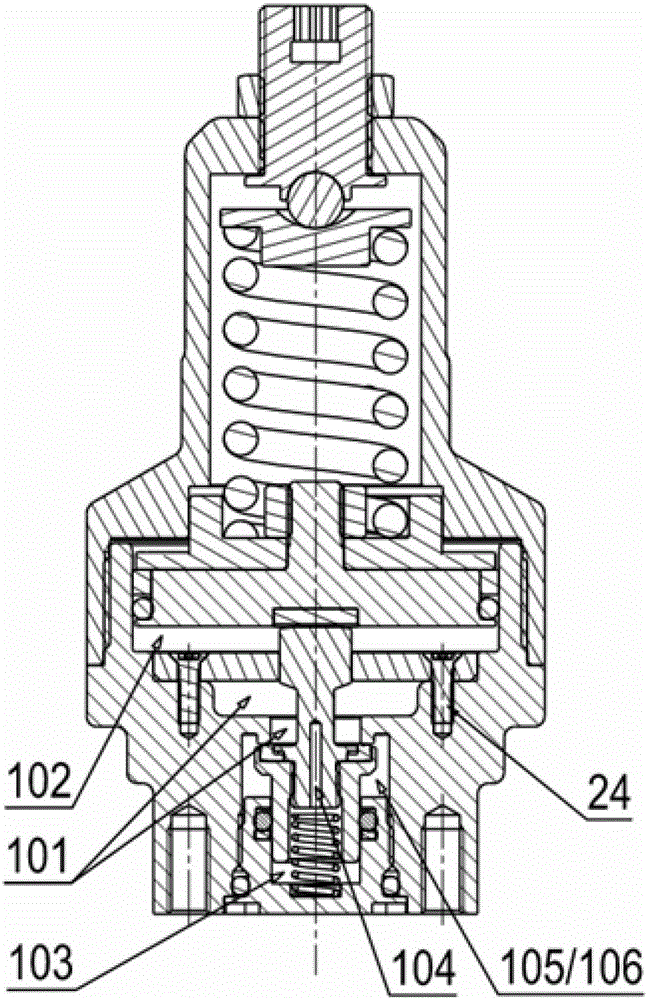

[0027] Such as Figure 1 to Figure 4 The structure of the present invention shown is a decompression chamber structure of a large-flow balanced pressure regulating valve.

[0028] In order to solve the problems existing in the prior art and overcome its defects, and realize the purpose of the invention that different flow requirements have little influence on the outlet pressure, the technical solution adopted by the present invention is:

[0029] Such as Figure 1 to Figure 4 As shown, a large-flow balanced pressure regulating valve of the present invention, the pressure regulating valve includes a valve body 01, a valve cover 02...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com