Distribution method and distribution structure of high-pressure water jet in heading machine cutterhead

A technology of high-pressure water jet and arrangement method, which is applied in the directions of earthwork drilling and cutting machinery, etc., can solve the problems of low construction efficiency, high maintenance cost, hob wear, etc., so as to improve construction efficiency, reduce construction cost and reduce wear and tear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

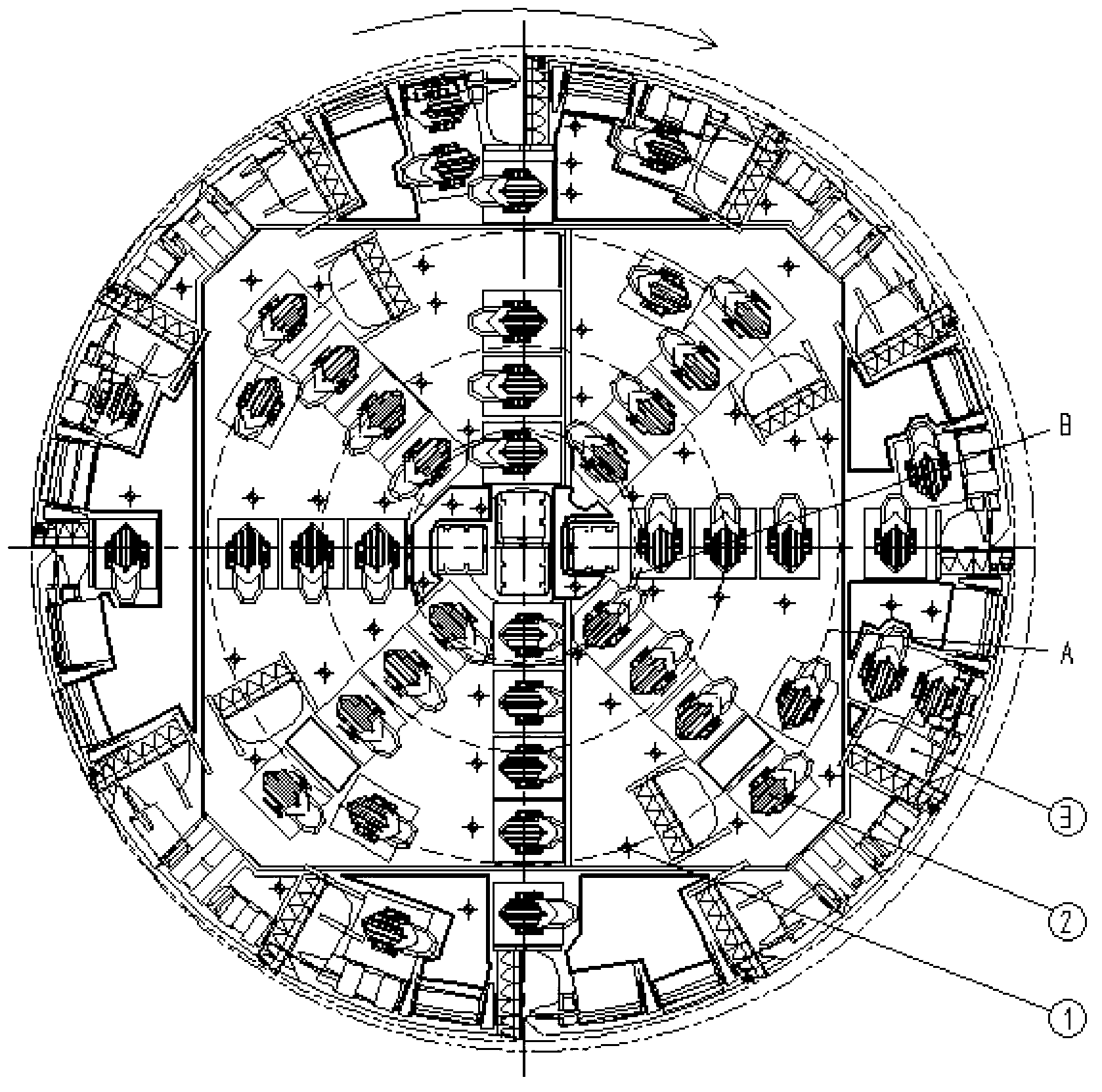

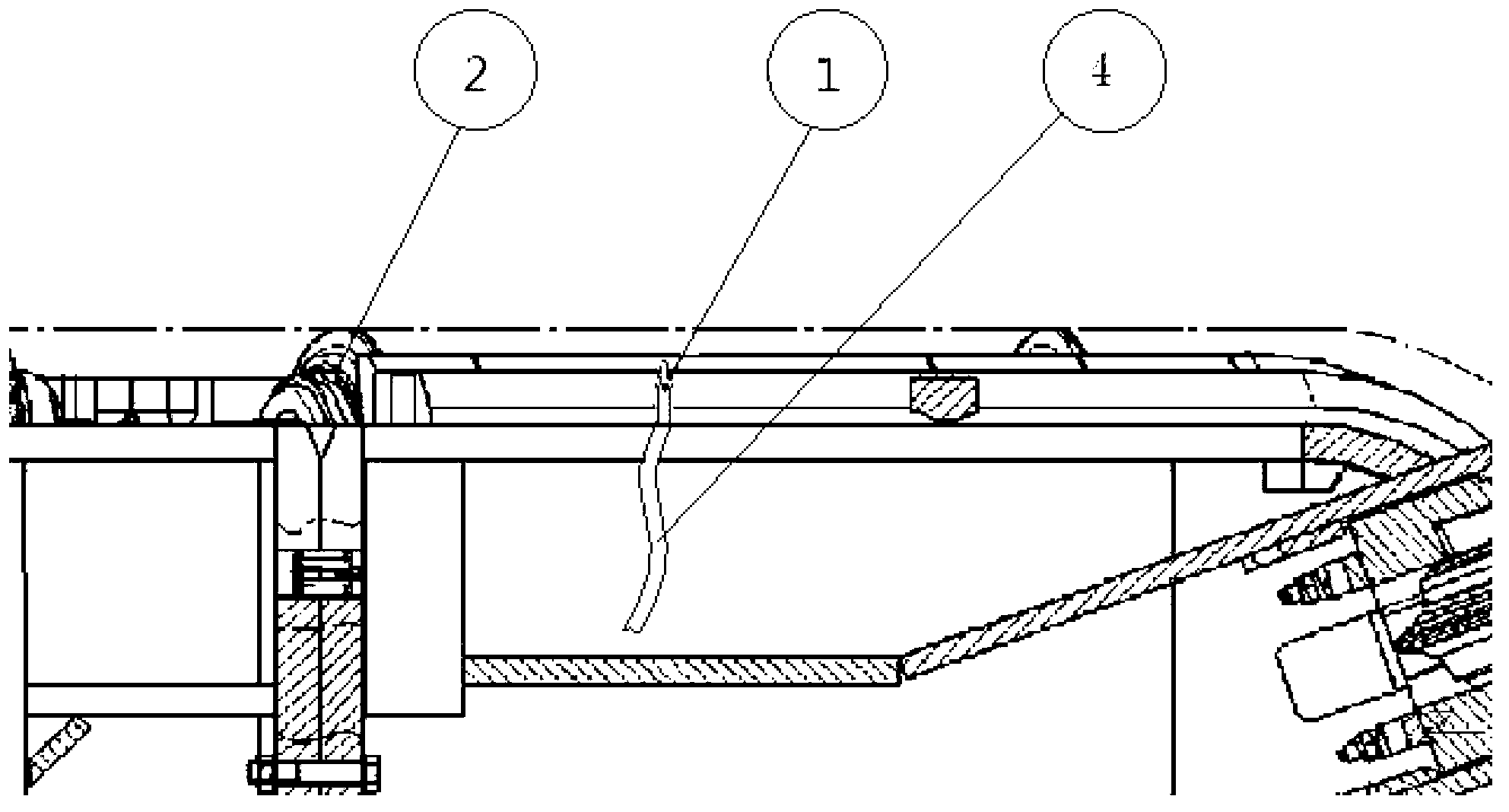

[0012] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions. Devices such as hobs and collecting ports are arranged on the cutter head of the existing rock boring machine, and the layout of the hobs is also different due to the difference in the diameter of the excavation surface and the mechanical properties of the rock. The hob is composed of shaft, bearing, seal, rotating cutter ring and rotating cutter body. The hob has no direct power. With the rotation of the cutter head of the roadheader, the rotating cutter ring rolls the rock, expanding the rock joints until it is broken or broken. Existing rock boring machines completely rely on the method of "head-to-head" to break rocks, and only rely on hob cutters to destroy rocks.

[0013] The present invention relates to a method and structure for arranging high-pressure water jets in a boring machine cutter head, comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com