Mechanical lock

A technology of mechanical locks and lock cylinders, applied in the field of mechanical locks, can solve the problems of low explosion-proof lock breaking ability and professional technology lock breaking ability, high cost of locks, complicated manufacturing, etc., to eliminate technical unlocking, strong anti-theft opening performance, The effect that there are few lock parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with accompanying drawing example:

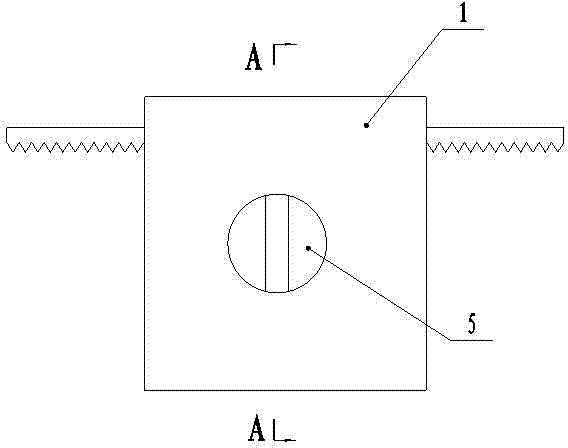

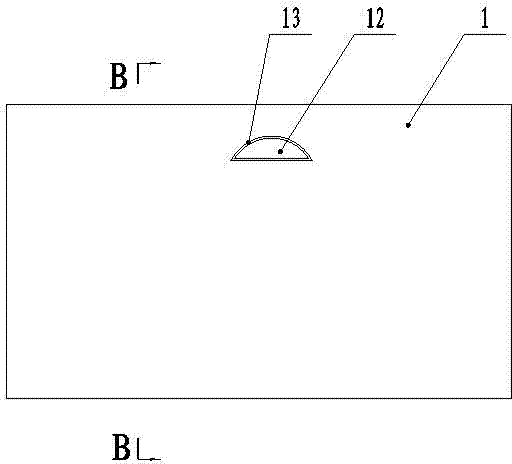

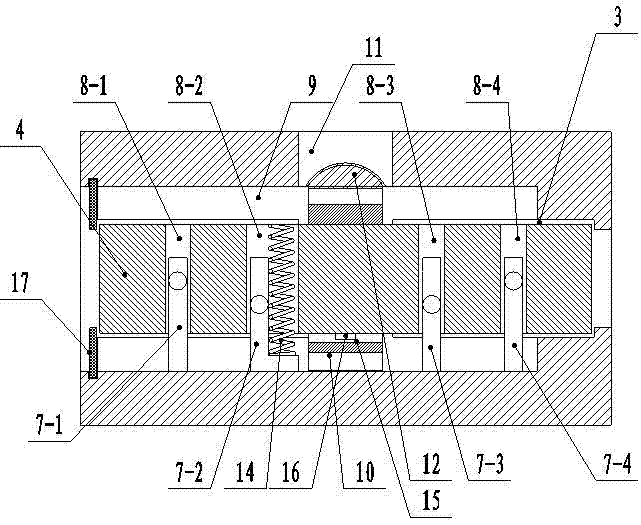

[0020] Such as Figure 1-Figure 4 The present invention shown, it comprises lock body 1 and is provided with the lock core 2 of key hole, and lock core 2 is contained in the slideway 3 of lock body 1, and lock core 2 is a hollow cylinder, and this lock core middle part is along The axial direction is provided with a barrier 4, which divides the inner cavity of the lock cylinder 2 into two symmetrical halves, wherein one side of the inner cavity is the key hole 5 outside the door, and the other port of the key hole outside the door is provided with a block; The inner cavity is the key hole 6 in the door, and the other port of the key hole in the door is also provided with a block, and a positioning snap ring 17 is crimped between the edge of the outer end of the lock core and the lock body 1, and the lock core 2 is connected from the lock body After the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com