Fruit, vegetable and tableware detergent with good rheological property

A fruit and vegetable tableware and detergent technology, applied in the direction of detergent compounding agent, detergent composition, organic washing composition, etc., to achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023]

[0024] The preparation method of the present embodiment is as follows:

[0025] 1. Add measured deionized water, add chelating agent, stir until completely dissolved.

[0026] 2. Add sodium dodecylbenzene sulfonate, sodium fatty alcohol polyoxyethylene ether sulfate, alkylamidopropyl betaine, alkyl glycoside, and PPG-20 methyl glucose ether in sequence (the control sample does not need to be added). Before adding, ensure that the previous raw material has been completely dissolved.

[0027] 3. Add preservatives and viscosity modifiers, and continue to stir until the materials are completely dissolved and uniform.

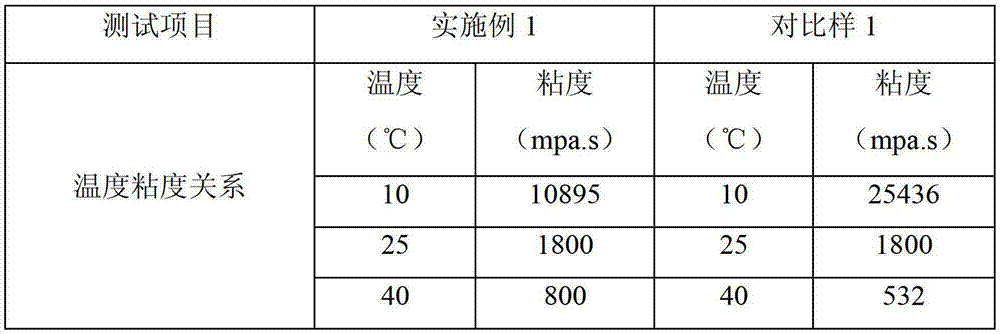

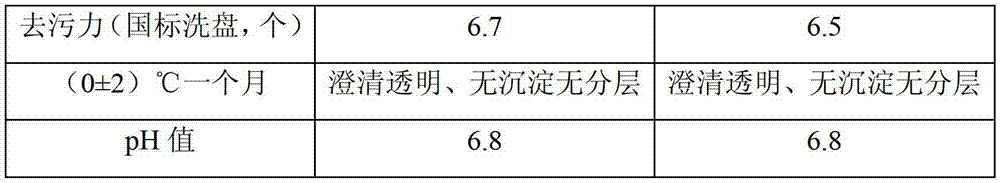

[0028] Carry out temperature-viscosity measurement to the detergent of embodiment 1, detergency measurement, stability measurement, pH value measurement, test result is shown in Table 1.

[0029] Table 1 The performance measurement of the detergent of embodiment 1 and comparative sample 1

[0030]

[0031]

[0032] As can be seen from Table 1, E...

Embodiment 2

[0034]

[0035] The preparation method of the present embodiment is as follows:

[0036] 1. Add measured deionized water, add chelating agent, stir until completely dissolved.

[0037] 2. Add sodium dodecylbenzene sulfonate, sodium fatty alcohol polyoxyethylene ether sulfate, alkyl amidopropyl ammonium oxide, alkyl glucoside, PPG-20 methyl glucose ether (no need to add to the control sample), PPG in sequence -10 Methyl Glucose Ether (no need to add to the control sample). Before adding, ensure that the previous raw material has been completely dissolved.

[0038] 3. Add preservatives and viscosity modifiers, and continue to stir until the materials are completely dissolved and uniform.

[0039] Carry out temperature-viscosity measurement to the detergent of embodiment 2, detergency measurement, stability measurement, pH value measurement, test result is shown in Table 2.

[0040] The performance measurement of the detergent of table 2 embodiment 2 and comparative sample ...

Embodiment 3

[0044]

[0045] The preparation method of the present embodiment is as follows:

[0046] 1. Add measured deionized water, add chelating agent, stir until completely dissolved.

[0047] 2. Add sodium dodecylbenzene sulfonate, sodium lauryl alanine, alkylamide propyl ammonium oxide, PPG-10 methyl glucose ether (no need to add for comparison sample), sodium xylene sulfonate (comparison do not need to join). Make sure that the previous raw material is completely dissolved before adding.

[0048] 3. Add preservatives and viscosity modifiers, and continue to stir until the materials are completely dissolved and uniform.

[0049] Carry out temperature-viscosity measurement to the detergent of embodiment 3, detergency measurement, stability measurement, pH value measurement, test result is shown in Table 3.

[0050] Table 3 The performance measurement of the detergent of embodiment 3 and comparative sample 3

[0051]

[0052] As can be seen from Table 3, Example 3 has good d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com