Rare earth ore collector, preparation method and ore dressing process of low-grade hard-selection rare earth ore

A rare earth ore and collector technology, applied in chemical instruments and methods, flotation, magnetic separation, etc., can solve the problems of difficult to obtain production indicators, poor operating conditions, and expensive chemicals, and expand the range of REO grades. , saving rare earth ore resources, and overcoming the effect of large influence of flotation operation

Active Publication Date: 2013-08-14

INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

View PDF3 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The process reagent is expensive, and heating is required during the flotation operation, which consumes a lot of energy, and the operating conditions are harsh, difficult to control, and difficult to obtain ideal production indicators.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

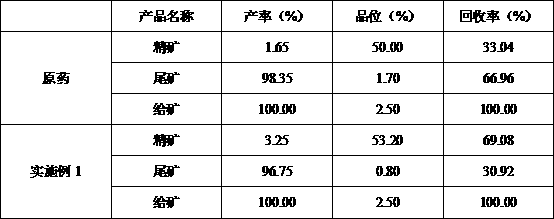

Embodiment 1

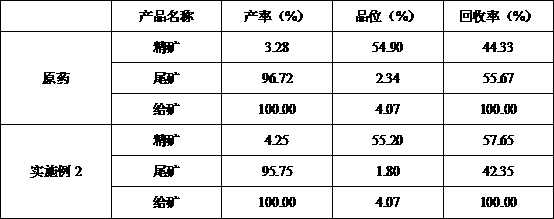

Embodiment 2

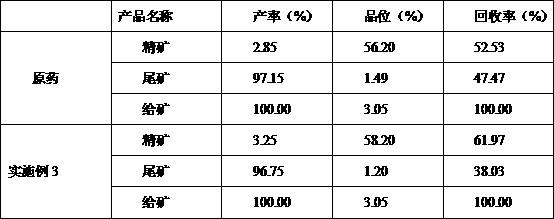

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a rare earth ore collector which is characterized in that the rare earth ore collector is obtained through reaction of 4-7 parts by weight of -naphthalene hydroxyl oxime acid, 2-4 parts by weight of methyl salicylate and a water solution containing 1-2 parts by weight of solid sodium hydroxide. The rear earth ore collector is simple in medicine compatibility, easy to prepare, low in cost, capable of being applied to flotation of complicated hard-selection low-grade rare earth ore and good in selection performance and collecting performance and simultaneously has no rigorous requirements on temperature and pH values of a flotation system. The invention further provides a preparation method of the collector, and the preparation method is simple to operate, easy in condition control and easy to implement. The invention simultaneously provides an ore dressing process of low-grade hard-selection rare earth ore, a flotation pre-enrichment - wet strong magnetic separation purification ore dressing method is adopted to obtain high-grade rear earth ore concentrate with high recovery rate. In the process, flotation pulp temperature is wide in application range, no warming is needed in a whole process, technological process is short, and recovery rate of low-grade complicated rear earth ore is improved remarkably.

Description

technical field [0001] The invention belongs to the technical field of rare earth beneficiation, and in particular relates to a collector that can be used for normal temperature flotation of rare earth ores, a preparation method thereof and a beneficiation process of low-grade refractory rare earth ores. Background technique [0002] Rare earth resources are known as the treasure house of high-tech and functional materials in the new century, and they are strategic elements for the development of high-tech. my country is very rich in rare earth resources, and the proven rare earth reserves account for about 80% of the world's total reserves. At the same time, my country is also one of the countries with the fastest growth in rare earth consumption in the world. It is expected that the demand for rare earths will continue to grow in the future. The research on beneficiation technology of rare earth ore is of great significance to the development of rare earth industry. W...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B03D1/004B03D1/00B03C1/00B03D101/02

Inventor 熊文良廖祥文曾小波邓善芝张新华

Owner INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com