Gearbox of corn combine harvester for spikes and stalks

A corn harvester and gearbox technology, which is applied in the field of gearboxes, can solve problems affecting the reliability of corn harvesters, complex header transmission, and easy damage to gears, and achieve easy lubrication, simple gearbox structure, and high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

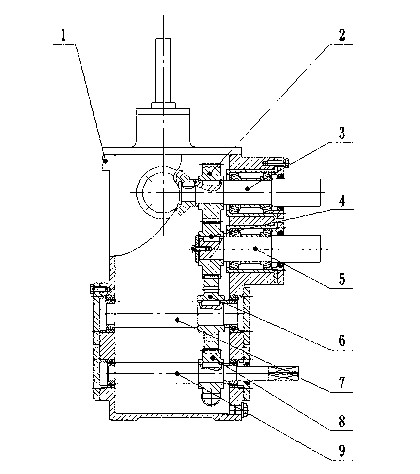

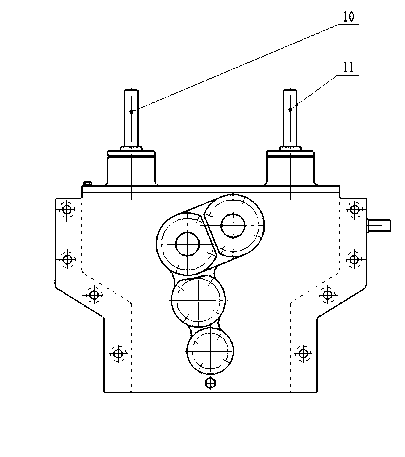

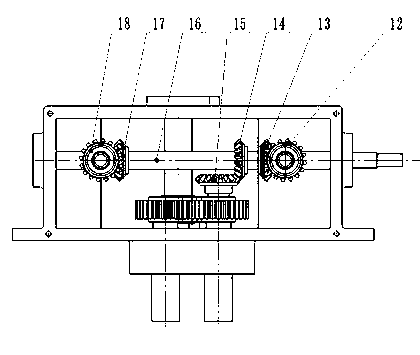

[0012] exist Figure 1 ~ Figure 3 The transmission box of the combined ear and stem harvester shown in the figure is installed on the rear panel of the backpack type corn harvester with both ear and stem harvesting, and mainly includes: box body 1, power input shaft 16, and driving chain II driving bevel gear 13. Active bevel gear 14 of upper fringe picking roller, active bevel gear 17 of reel chain I, drive shaft 10 of reel chain I, passive bevel gear 18 of reel chain I, drive shaft 11 of reel chain II, passive reel chain II Bevel gear 12, upper ear picking roller shaft 3, upper ear picking roller spur gear 2, lower ear picking roller shaft 5, lower ear picking roller spur gear 4, intermediate drive shaft 7, intermediate drive spur gear 6, shredding hob shaft 9. Shred hob spur gear 8. It is characterized in that: the power input shaft 16 is installed on the box body 1, on which are installed the driving bevel gear 13 of the reel chain II, the driving bevel gear 14 of the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com