Sound-insulation shield of compressor

A technology for compressors and soundproof enclosures, applied in mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve the problems of difficulty in effectively blocking noise, inconvenient use and maintenance, poor aging resistance, etc., to enhance the sound insulation effect, processing Convenience, ensuring stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

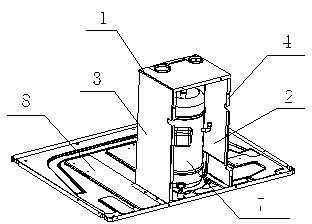

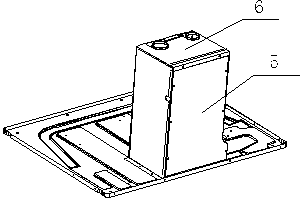

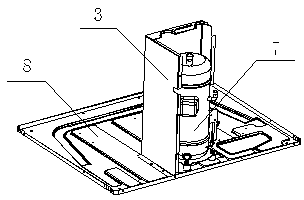

[0024] As shown in the figure, the compressor sound insulation cover of this implementation includes a galvanized sheet shell 1, and the inner layer of the galvanized sheet shell 1 is provided with a felt sound-absorbing lining 2; the galvanized sheet shell 1 has an integral or split structure; When the casing 1 is a split structure, the galvanized sheet casing 1 is composed of a left plate 3, a right plate 4, a front plate 5 and a top plate 6, wherein the left plate 3, the right plate 4 and the front plate 5 are combined with the compressor 7 from all sides, The top plate 6 is installed on the upper part of the left plate 3, the right plate 4 and the front plate 5; the cross-sectional shape of the left plate 3 of the galvanized sheet shell 1 in the horizontal direction is "L"; the thickness of the galvanized sheet shell 1 is 1.2mm; The thickness of the sound-absorbing lining 2 is 10 mm; the felt sound-absorbing lining 2 is pasted on the inner layer of the galvanized sheet shel...

Embodiment 2

[0031] The similarities between this embodiment and Embodiment 1 will not be repeated, and the difference is:

[0032] The thickness of the galvanized sheet shell 1 is 1.0 mm.

Embodiment 3

[0034] The similarities between this embodiment and Embodiment 1 will not be repeated, and the difference is:

[0035] The thickness of the galvanized sheet shell 1 is 1.5mm.

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com