Experimental calibration method of saturation degree and water production rate logging evaluation model of water-flooded layer

A calibration method and water production rate technology, applied in the field of experimental physics testing, can solve problems such as the inability to accurately measure the resistivity of formation water that cannot be mixed, and it is difficult to establish a water-flooded oil layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

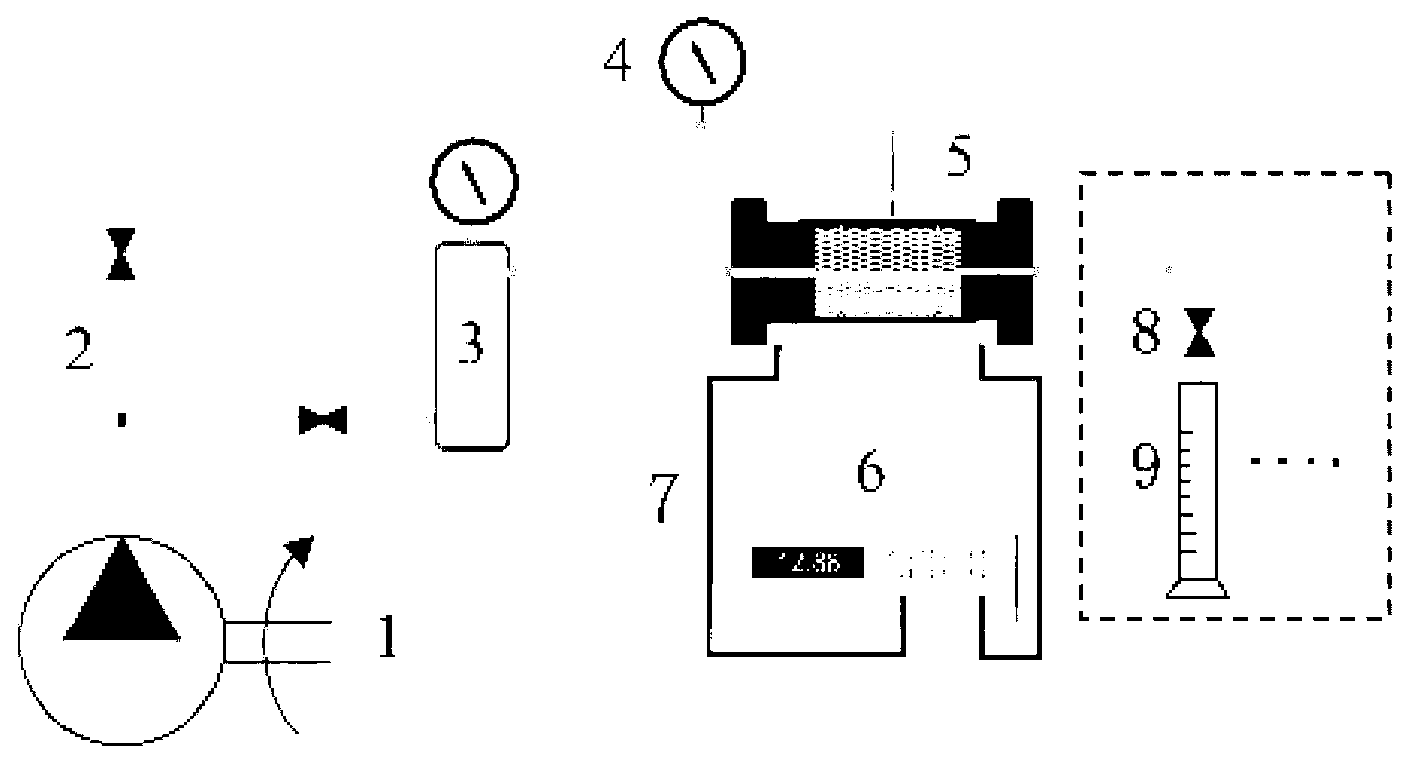

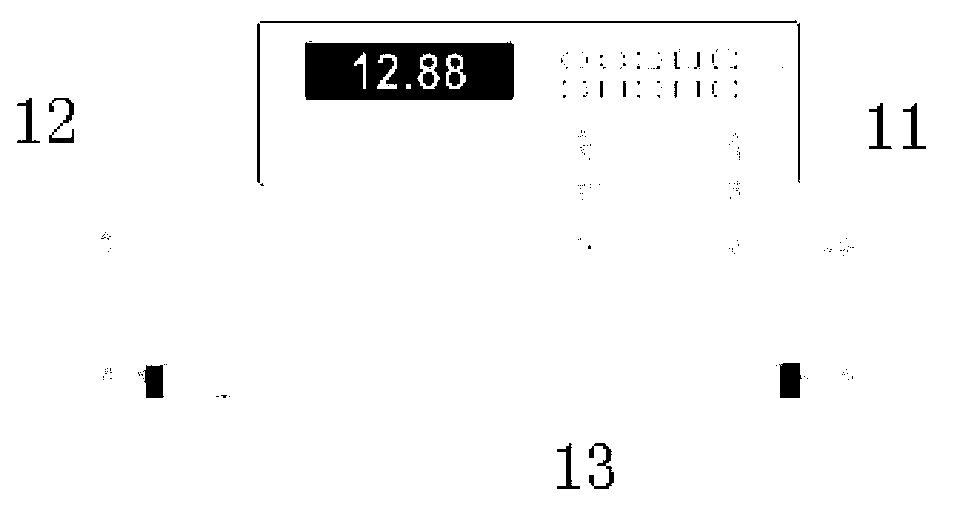

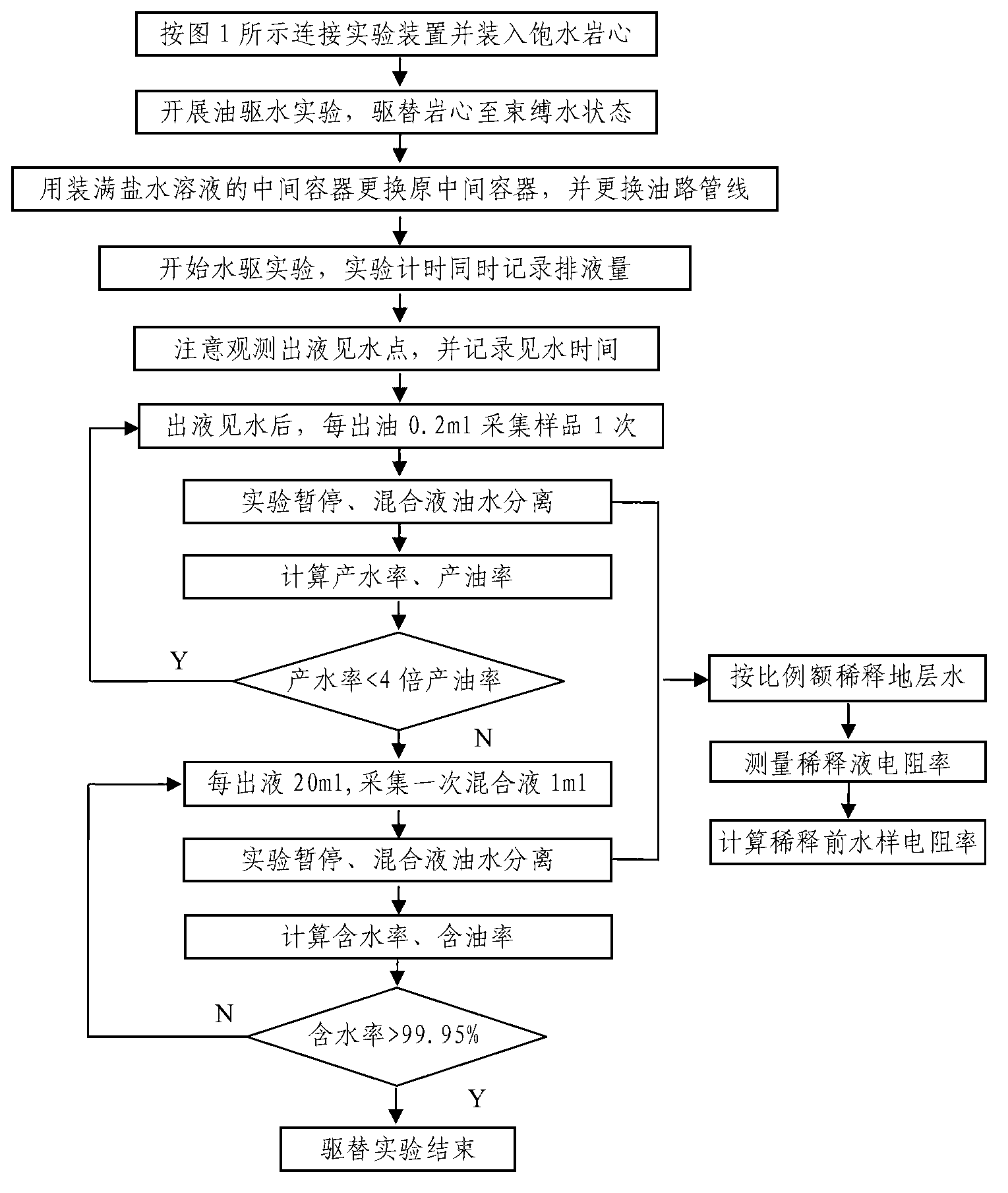

Image

Examples

Embodiment 1

[0032] Taking the core of the GD Oilfield as an example, the salinity of the original formation water in the reservoir is 3000mg / L, and the salinity of the injected water is 14000mg / L. After sampling, the experimental measurement is carried out. The specific operation steps are as follows:

[0033] 1) Measure the resistivity of the saturated water sample and record it as R 0 , the cementation index m is obtained after calculating the formation factor F according to formula (1).

[0034] F = R o R w = 1 Φ m - - - ( 1 )

[0035] 2) Flood the water-saturated sample oil to the state of irreducible water, and determine the irreducible water saturation Swi.

[0036] 3) Measure the effective permeability of the oil ...

Embodiment 2

[0048] The salinity of the original formation water in the DX oilfield reservoir is 4200mg / L, and the salinity of the injected water is 10000mg / L. The core is selected for experimental measurement. The specific operation steps are the same as in Example 1, and the experimental data processing is the same as in Example 1. Finally, the experimental statistical relationship between water content and water saturation is obtained as f w =0.4868ln(Sw)+1.0856, the coefficient is R 2 =0.96 (see Figure 7 ). R w =0.7137f w 2 -1.5902f w +1.466, the coefficient is R 2 =0.97 (see Figure 8 ). The resistivity of rock samples, resistivity of mixed formation water, water saturation and saturation index n were observed experimentally, and the saturation index n was determined to be 1.65 (see Figure 9 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com