Flat woven steel rope sling

A steel rope and rope technology, applied in the field of flat braided steel rope rigging, can solve the problems of easy cracking, spreading and falling off of grommets, and achieve the effect of ensuring service life, ensuring use effect, and not easy to crack and fall off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The invention relates to a flat braided steel rope sling, which is braided by a steel rope.

[0018] The weaving steps of the flat braided steel rope sling are as follows:

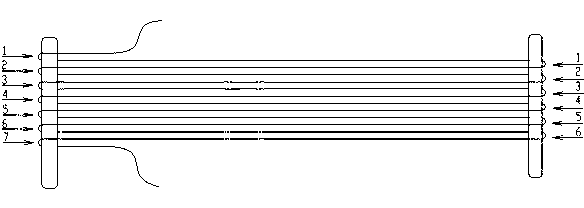

[0019] Step 1: Take a piece of steel rope that reaches the required length and wind it between two fixed rods I and II arranged vertically from top to bottom or from bottom to top in the same direction. The fixed rod I is wound for seven weeks and fixed The rod II is wound for six times, and the front row of steel ropes and the rear row of steel ropes are formed between the fixed rod I and the fixed rod II. The first and last circles of the steel rope wound on the fixed rod I form two free ends of the steel rope ;(Such as figure 1 )

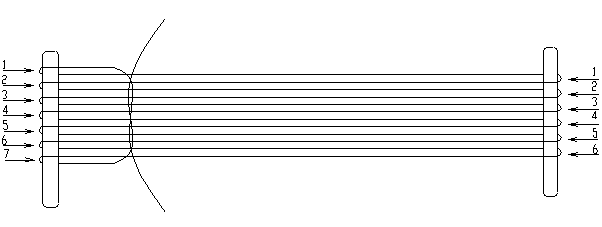

[0020] Step 2: Cross knot the two free ends of the steel rope, tighten the knot between the front row of steel ropes and the rear row of steel ropes, and pull the two free ends of the steel ropes out to the front row of steel ropes and the back row of steel Outside the rope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com