Foldable flexible lifting mechanism of vehicle body correcting machine

A technology of lifting mechanism and correction machine, which is applied in the direction of lifting frame, lifting device, etc., can solve the problems of affecting the stiffness of bearing stability components, affecting the stability of component connection, occupying maintenance space, etc., to achieve stable and reliable working conditions and protection devices Effect of simplifying and increasing maintenance space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

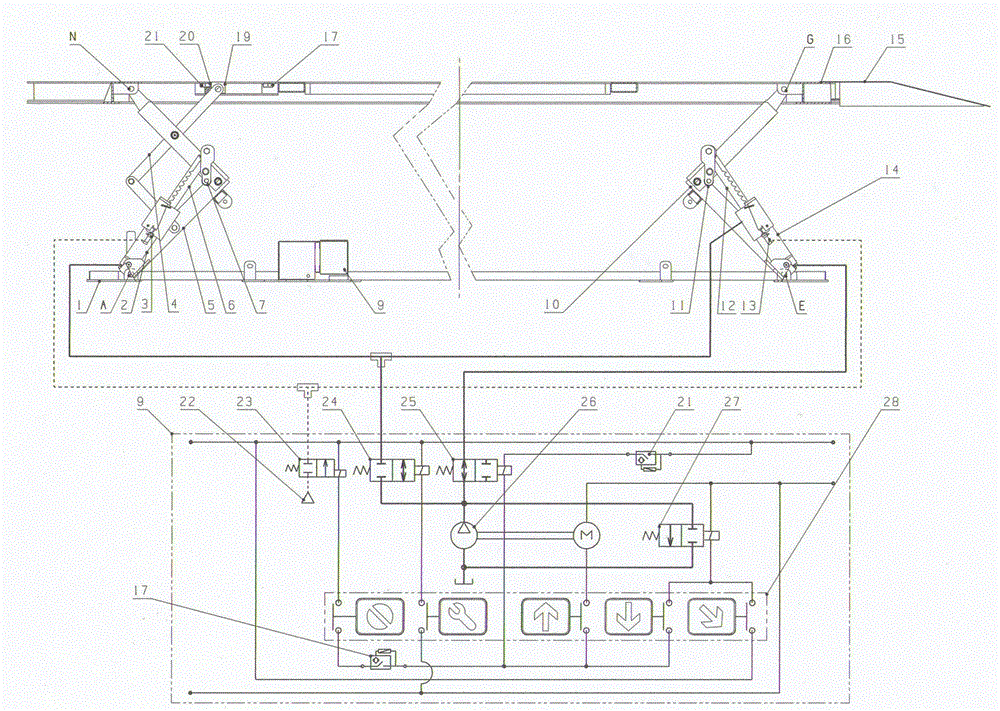

[0032] like figure 1 , the present invention includes a base 1, a platform 16, a rear support arm 5 connected between the base 1 and the platform 16, a front support arm 10, and a control device 9 for controlling the lifting and tilting of the platform 16.

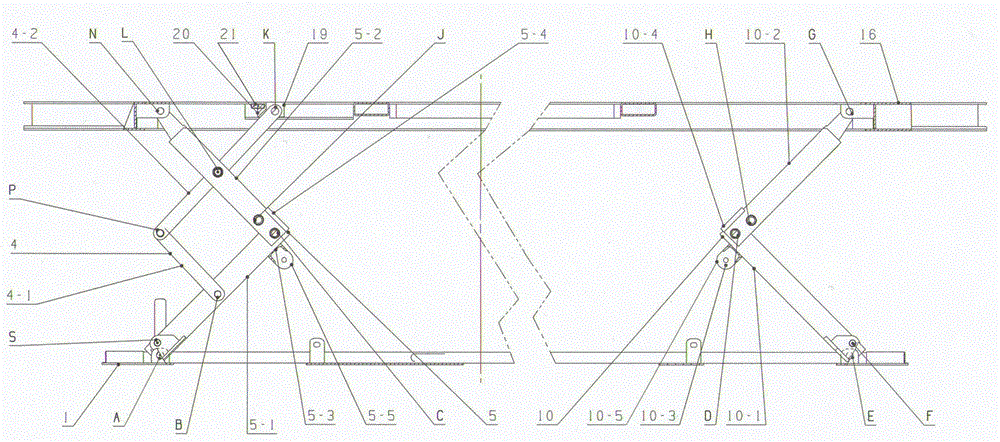

[0033] The base 1 is respectively provided with a first hinge support A and a second hinge support E positioned in front of the first hinge support A; A and the second hinge support E are one-to-one corresponding to the third hinge support N and the fourth hinge support G.

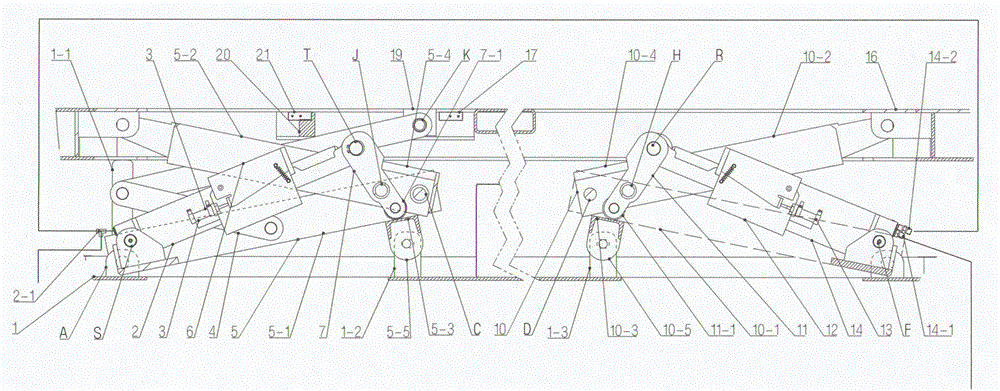

[0034] like figure 2, the rear arm 5 includes a rear lower arm 5-1 and a rear upper arm 5-2, and also includes a rear arm hinge C connected to the front ends of the rear lower arm 5-1 and the rear upper arm 5-2; the rear lower arm The lower end of the 5-1 is provided with a rear lower hinge support shaft; the upper end of the rear upper arm 5-2 is provided with a rear upper hinge support shaft; the rear support arm 5 is supported by the rear lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com