Self-expansion packer

A self-expanding and packer technology, which is applied in the field of oil drilling and well completion operations, can solve problems such as inability to effectively prevent rubber extrusion and tearing, unsatisfactory sealing ability, and affecting sealing ability, and achieve pressure maintenance Solidity, compact structure, easy to enter the well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below based on the accompanying drawings.

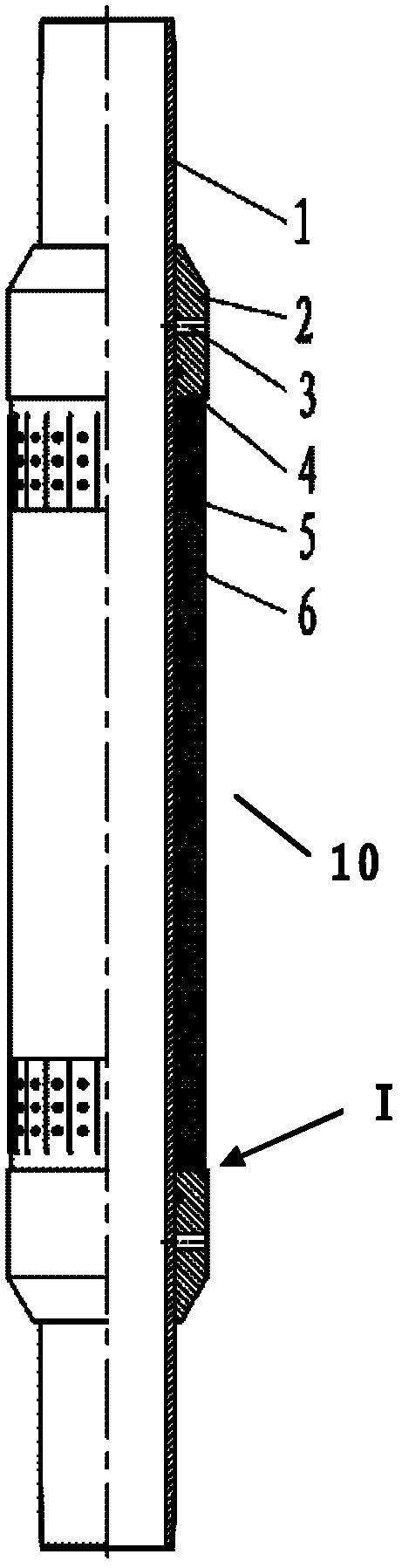

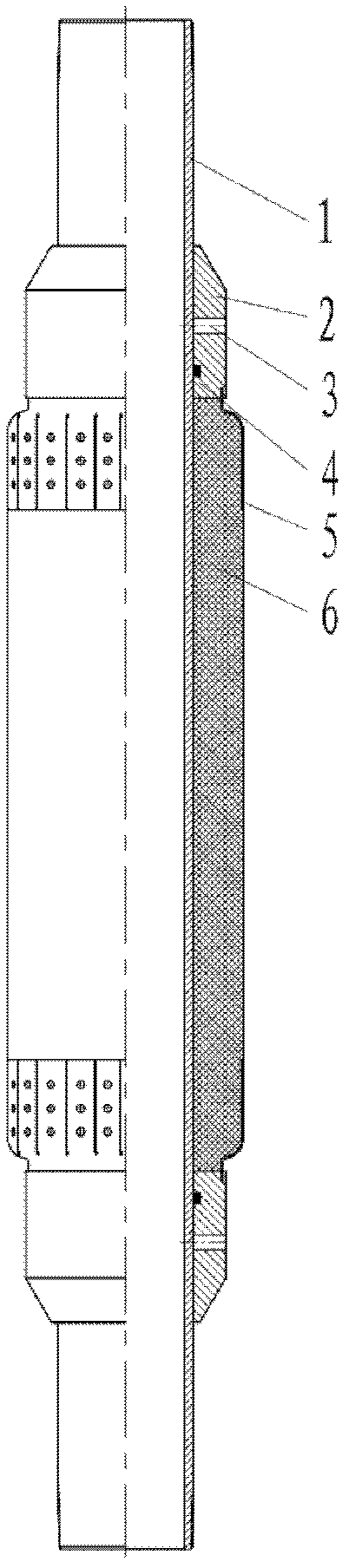

[0024] Such as figure 1 As shown, a self-expandable packer 10 according to the present invention includes a base pipe 1 . The base pipe 1 can be in the form of API casing or tubing, for example, and its upper and lower ends are threaded so as to be connected with the upper and lower completion strings.

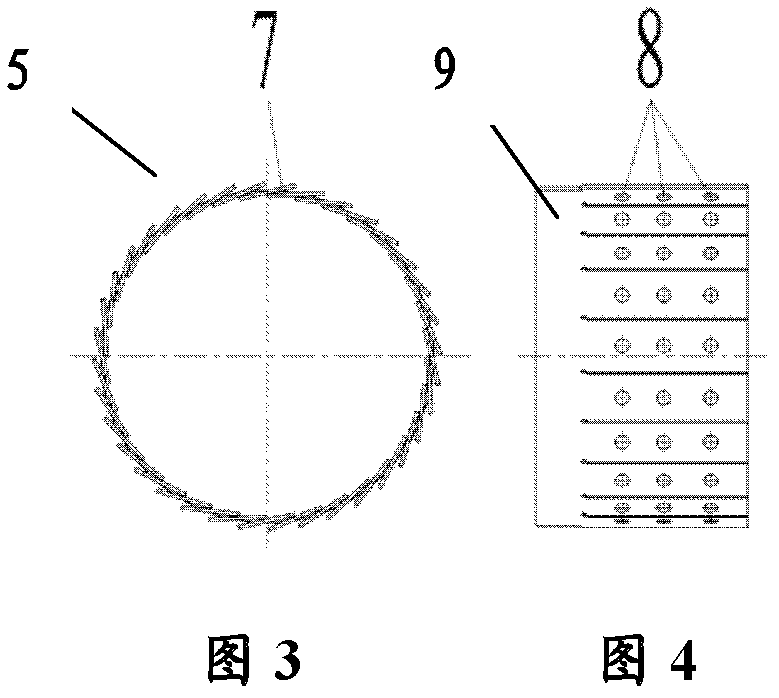

[0025] A self-expanding rubber sleeve 6 is arranged around the base pipe 1 . The rubber cartridge 6 can be vulcanized on the base pipe 1 by winding or molding, for example. The material and length of the rubber cartridge 6 can be customized according to specific well conditions. When the packer 10 is lowered to a predetermined position at the bottom of the well along with the well completion string and contacts liquid such as crude oil or water, the rubber sleeve 6 will absorb the oil or water and expand.

[0026] The packer 10 also includes a limiting end ring 2 , which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com