Preparation method of anti-oxidative high-temperature-resistant cysteamine hydrochloride preparation, and application of preparation

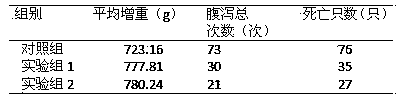

A cysteamine hydrochloride, high temperature-resistant technology, applied in the application, animal feed, additional food elements, etc., can solve the problems of product stability and effect decline, unable to ensure full protection of cysteamine hydrochloride, etc. Antioxidant gastrointestinal function, improve gastrointestinal function, improve the effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

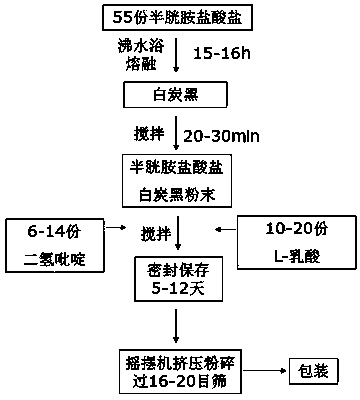

[0026] 1. Treat cysteamine hydrochloride in a plastic container in a boiling water bath for 15 hours until it completely melts;

[0027] 2. Slowly add 55 parts of molten cysteamine hydrochloride to 29 parts of white carbon black under stirring, and continue stirring for 30 minutes until it becomes a uniform powder;

[0028] 3. Add 6 parts of dihydropyridine and 10 parts of L-lactic acid to the homogeneous powder of cysteamine hydrochloride and white carbon black, and mix well until it becomes a uniform powder;

[0029] 4. Leave the obtained uniform powder in a sealed plastic film bag for 7 days;

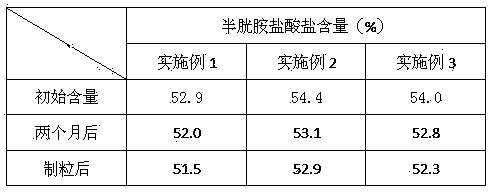

[0030] 5. Pulverize the stable product that has been agglomerated after the reaction in a swinging granulator and pass through a 16-mesh sieve to obtain an anti-oxidation and high-temperature resistant cysteamine hydrochloride preparation. The content of cysteine hydrochloride is 52.9% by sampling. After passing the test, it is packaged and put into storage.

Embodiment 2

[0032] 1. Treat cysteamine hydrochloride in a plastic container in a boiling water bath for 16 hours until it completely melts;

[0033] 2. Slowly add 55 parts of molten cysteamine hydrochloride to 11? In the amount of white carbon black, continue to stir for 30 minutes until it becomes a uniform powder;

[0034] 3. Add 14 parts of dihydropyridine and 20 parts of L-lactic acid to the homogeneous powder of cysteamine hydrochloride and white carbon black, and mix well until it becomes a uniform powder;

[0035] 4. Leave the obtained uniform powder in a sealed plastic film bag for 12 days;

[0036] 5. Pulverize the stable product that has been reacted and agglomerated in a swinging granulator and pass through a 16-20 mesh sieve to obtain an anti-oxidation and high-temperature resistant cysteamine hydrochloride preparation. The content of cysteine hydrochloride is 54.4% by sampling. %, after passing the test, it is packaged and put into storage.

Embodiment 3

[0038] 1. Treat cysteamine hydrochloride in a plastic container in a boiling water bath for 16 hours until it completely melts;

[0039] 2. Slowly add 55 parts of molten cysteamine hydrochloride into 20 parts of white carbon black under stirring, and continue stirring for 20 minutes until it becomes a uniform powder;

[0040] 3. Add 10 parts of dihydropyridine and 15 parts of L-lactic acid to the homogeneous powder of cysteamine hydrochloride and white carbon black, and mix well until it becomes a uniform powder;

[0041] 4. Leave the obtained uniform powder in a sealed plastic film bag for 10 days;

[0042]5. Pulverize the stable product that has been reacted and agglomerated in a swinging granulator and pass through a 20-mesh sieve to obtain an anti-oxidation and high-temperature-resistant cysteamine hydrochloride preparation. Sampling checks that the content of cysteine hydrochloride is 53.4%. After passing the test, it is packaged and put into storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com