Pipe bursting apparatus

一种地下管、安装杆的技术,应用在管元件、管子/管接头/管件、钻孔设备和方法等方向,能够解决体力困难、复杂、增加制造成本等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

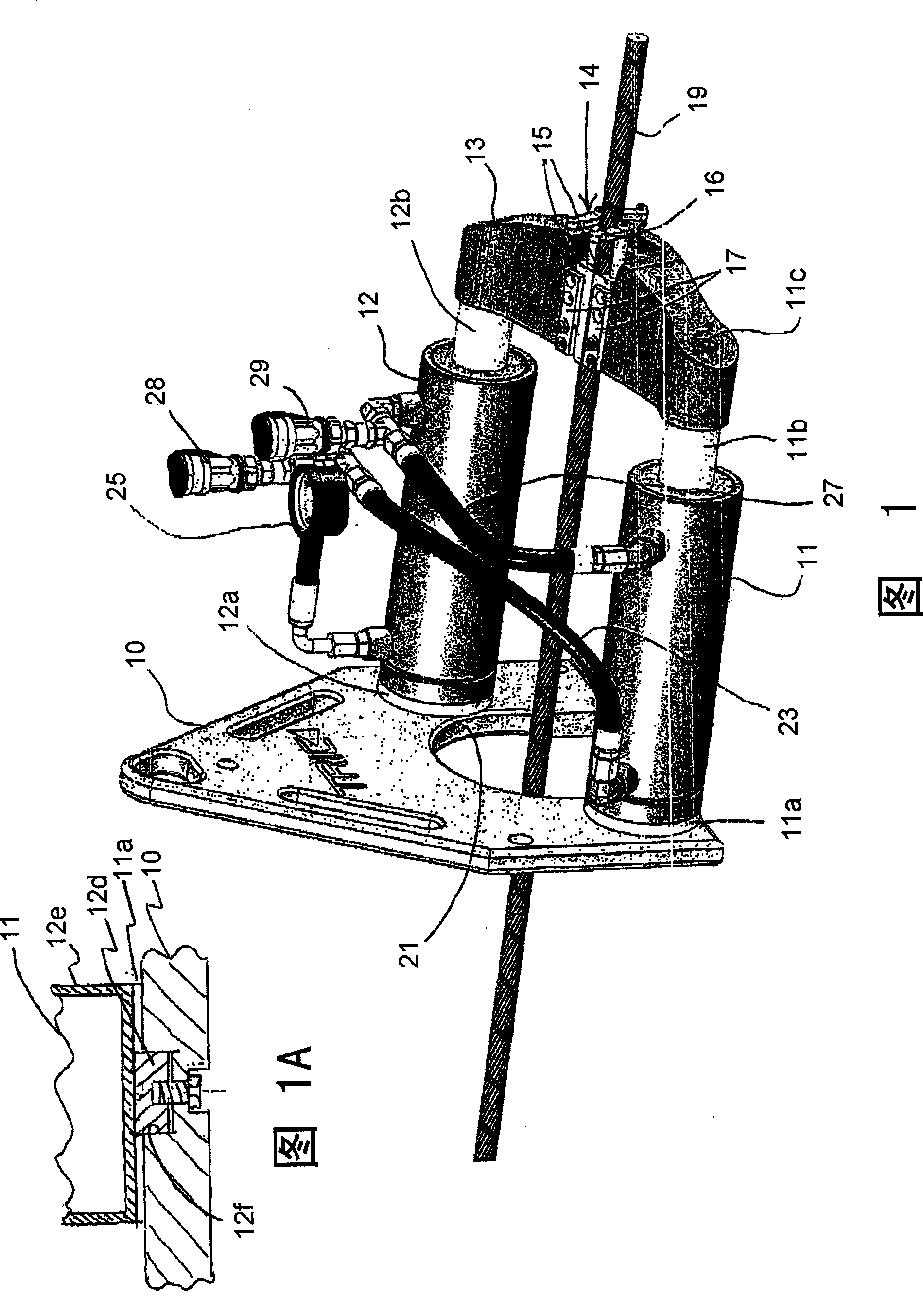

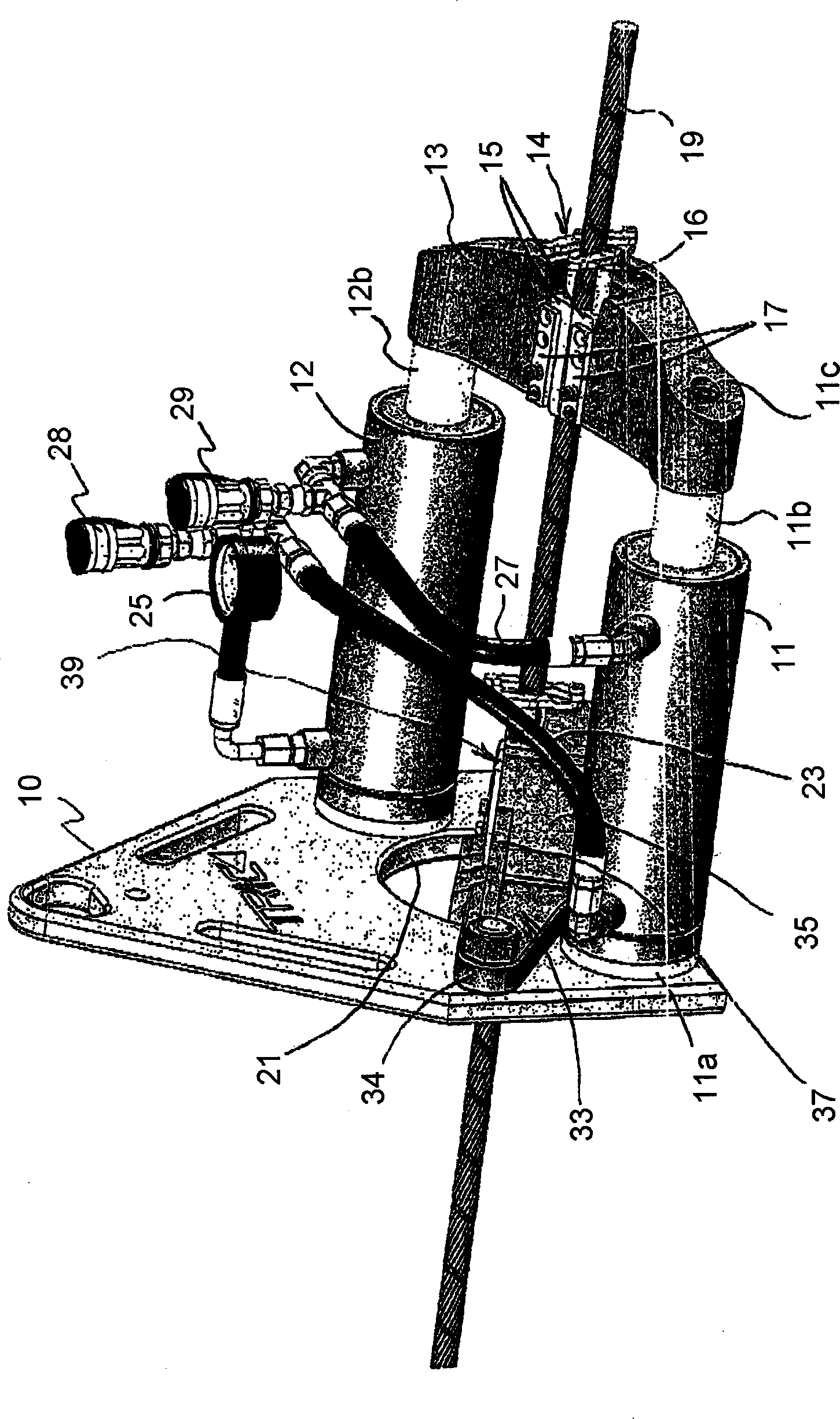

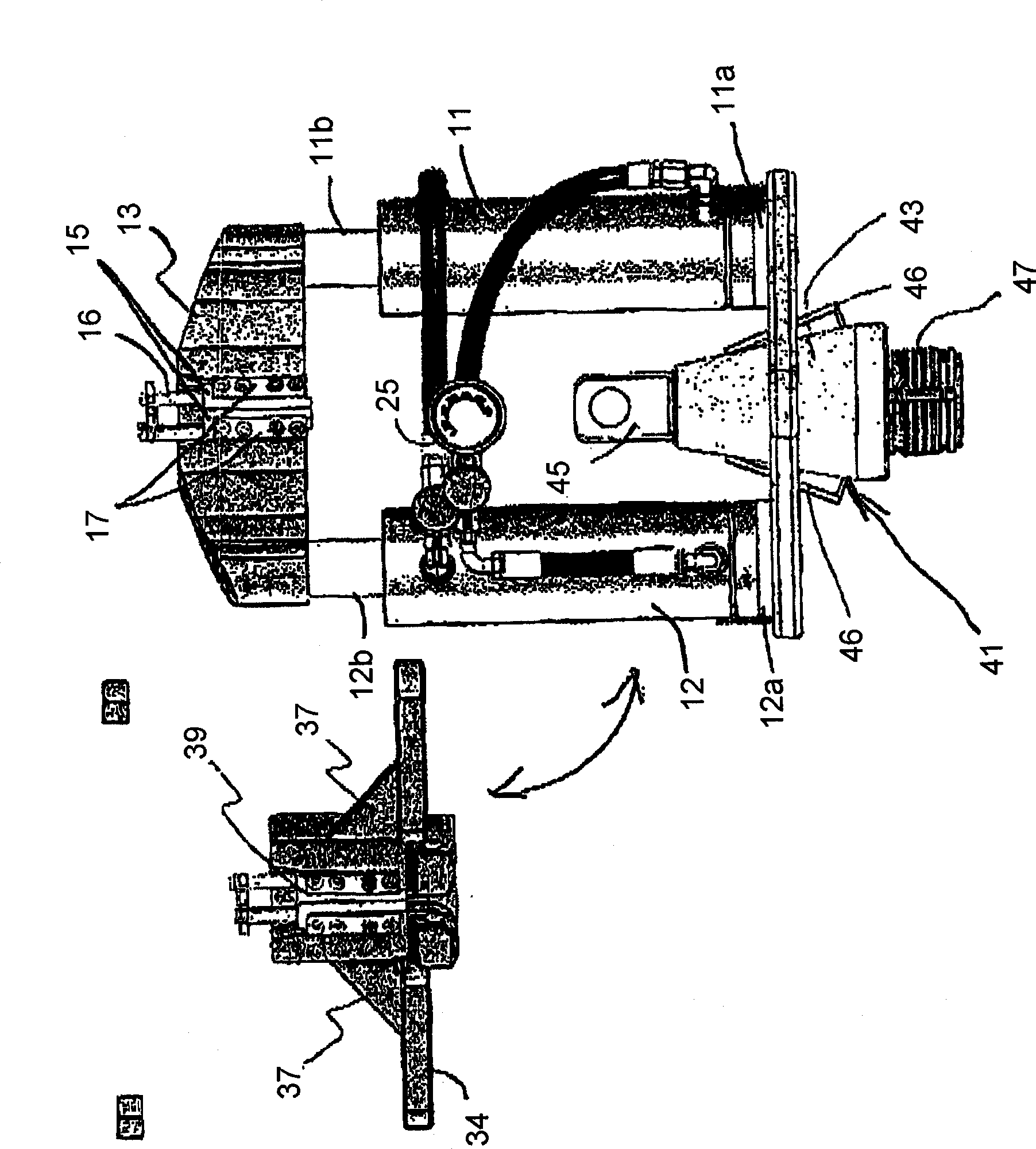

[0014] see figure 1 and 2 , describes a preferred form of the device of the invention. The reaction plate 10, also known as the drag plate, is preferably 18 to 24 inches wide, about the same size in height, and one to two inches thick. The reaction plate 10 is preferably steel or similar material. The reaction plate is positioned within a well at one end of the pipe section being replaced to bear against the wall of the well from which the pipe section normally emerges. Wood or equivalent material may be placed between the reaction plate and the pit walls as desired to distribute the load. In any event, the reaction plate supports the other components of the device as will be described. As shown, the reaction plate may have unnumbered openings for ease of handling and weight reduction.

[0015] The reaction plate 10 is also provided with another opening or slot 21 to allow the pull cable 19 to pass through the reaction plate. Because the slot 21 runs through one side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com