Weak detonation tank for pulse soot blower

A soot blower and pulse technology, which is applied to the field of weak deflagration tanks for pulse soot blowers, can solve the problems of wasting materials, insufficient shock soot blowing force, etc., and achieve the effects of cost reduction, humanized control, mixing and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

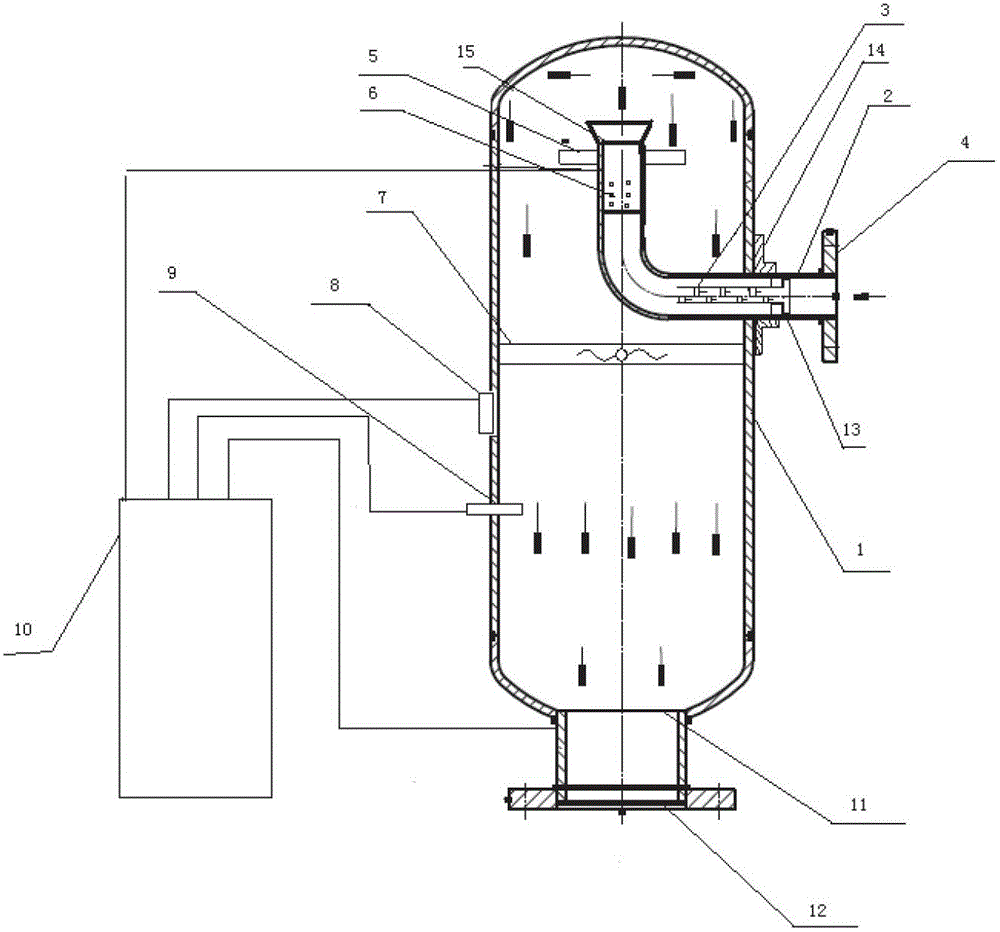

[0025] Such as figure 1 As shown, a weak deflagration tank for a pulse soot blower includes: a tank body 1 with an air outlet 12 disposed thereon. The inner wall of the tank body 1 is covered with a layer of high temperature resistant material coating. The air intake pipe 2, the air intake pipe 2 includes a horizontal section and a vertical section, the horizontal section and the vertical section are connected to each other as a whole, wherein the horizontal section is inserted from the side of the tank body 1 relative to two-thirds of the height of its bottom To the inside of the tank body 1, and the air inlet pipe 1 is away from the fuel outlet 12, and extends to the axis of the tank body, the vertical section extends upward along the axis of the tank body 1, and the end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com