Full-automatic glue spraying and box making production line

A production line, fully automatic technology, applied in container manufacturing machinery, box manufacturing operations, rigid/semi-rigid container manufacturing, etc., can solve the problems of low production efficiency, poor manufacturing accuracy, and high production costs, reducing labor costs, sticking The effect of firm fit and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

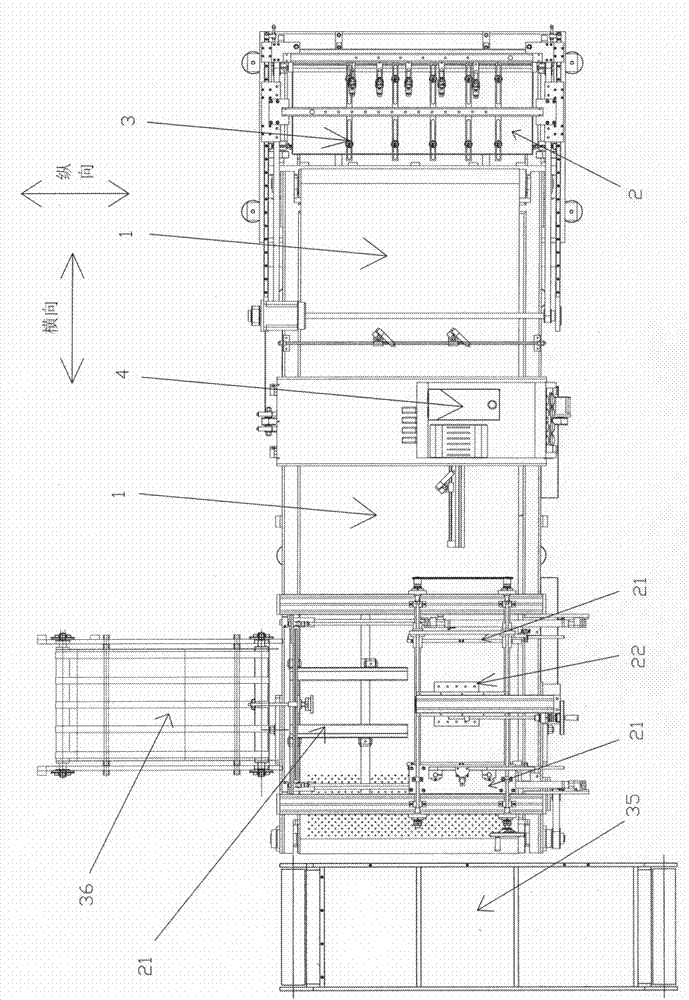

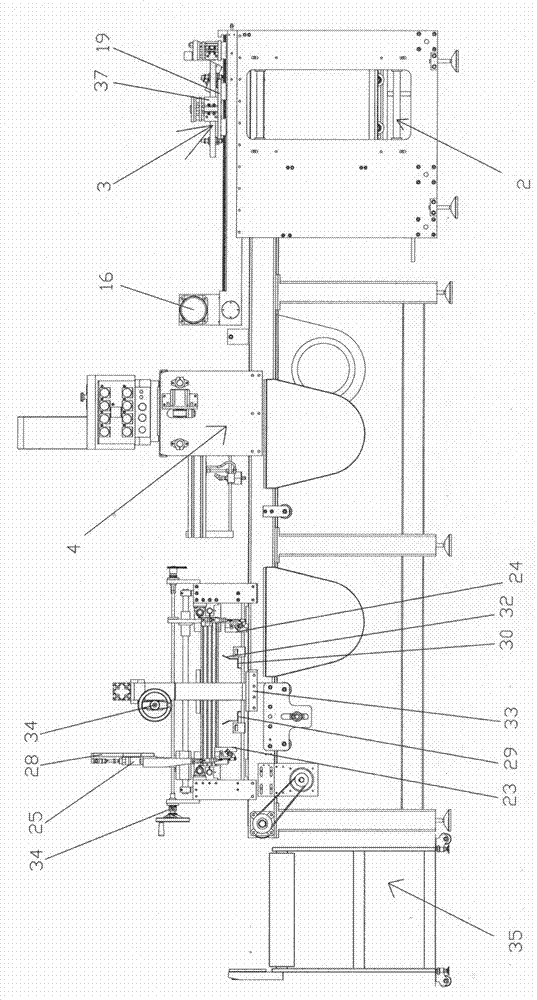

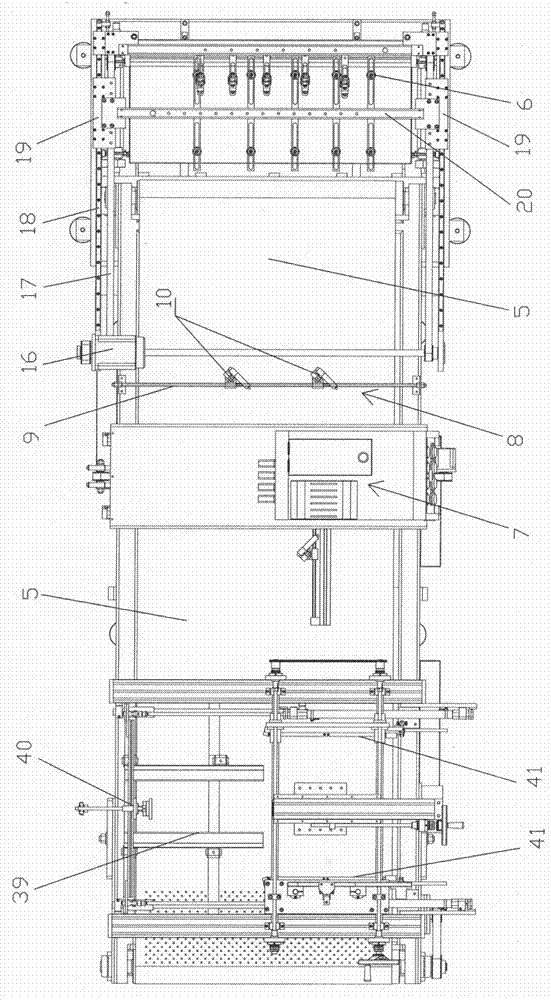

[0025] combined with Figure 1~3 , a full-automatic glue-spraying box-making production line, including a frame, the frame is provided with a conveying mechanism 1, a board feeding mechanism 2, a transfer manipulator 3, a glue spraying mechanism 4, a box-feeding positioning mechanism 21 and a box-releasing mechanism 22, The conveying mechanism 1 includes a conveyor belt 5 arranged on the frame and driven by a power source. The conveyor belt in this embodiment adopts a suction belt, so that the cardboard can be transported more stably and the glue on the surface of the cardboard will not be affected; The transfer manipulator 3 is arranged between the plate feeding mechanism 2 and the conveying mechanism 1, the glue spraying mechanism 4 is arranged above the conveying path of the conveyor belt, and the box sending positioning mechanism 21 sends the box body to the lamination on the conveyor belt. At the station, the box putting mechanism 22 is arranged above the pasting station....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com