High-rigidity low-deformation movable template

A technology of moving formwork and low deformation, applied in the field of high rigidity and low deformation moving formwork, can solve the problems of polluted products, increase the weight of moving formwork, reduce the precision of moving formwork, etc., and achieve the effect of eliminating pollution, low stress distribution and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

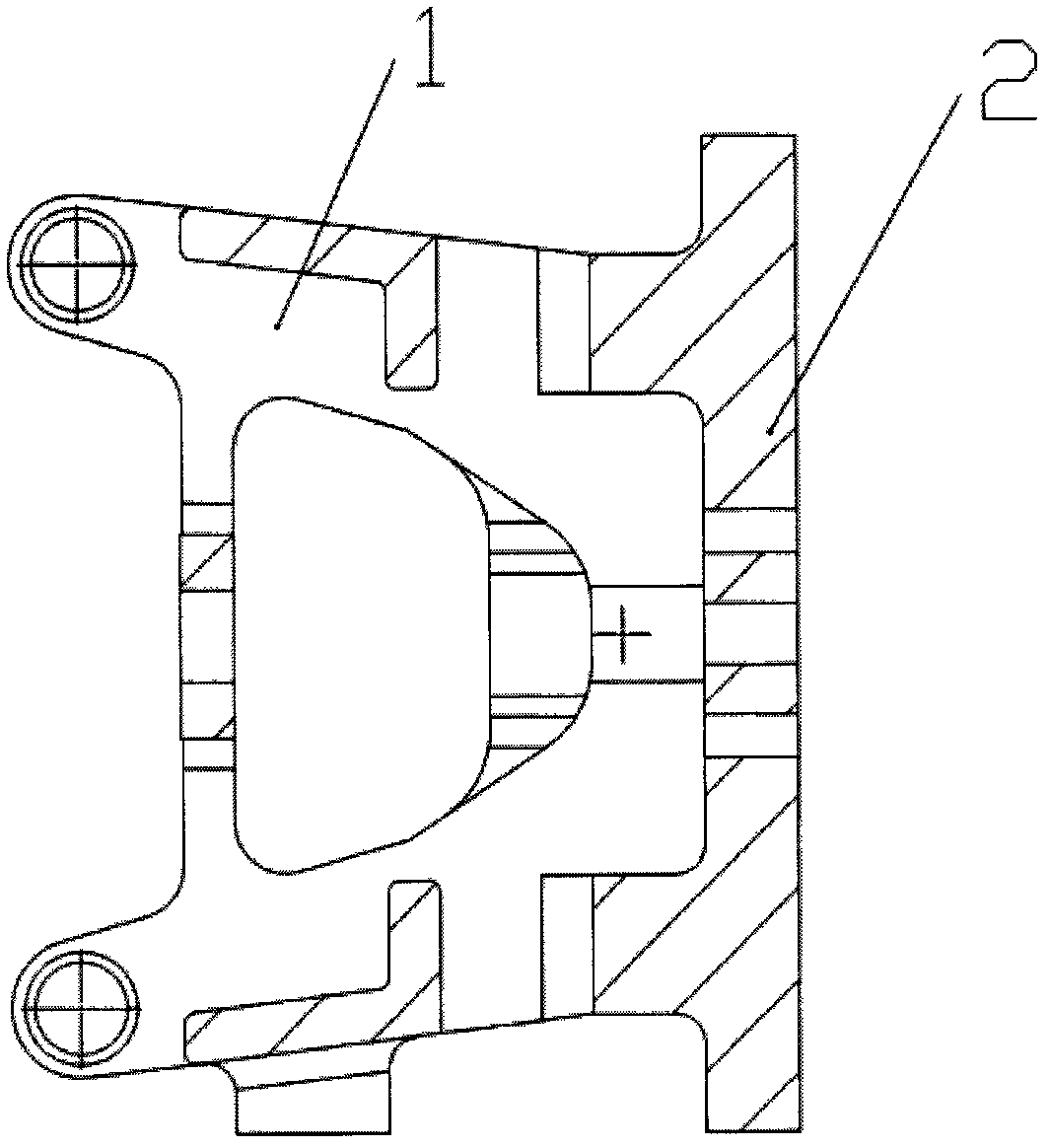

[0012] Such as figure 1 , figure 2 As shown, a high-rigidity and low-deformation movable formwork, which includes an A-shaped hinged ear frame (1), a dynamic formwork code mold surface (2), a central boss (3), an arc groove (4), and a small step surface (5), the A-shaped top of the A-shaped hinged ear frame (1) is provided with a moving template code mold surface (2), and the center positions of the left and right sides of the movable template code mold surface (2) are provided with a center The boss (3) can be equipped with a linear guide rail support and a linear guide rail. The four corners of the moving template code mold surface (2) are provided with arc grooves (4) to avoid pull bars. The movable template code mold surface ( 2) A tiny step surface (5) is set to counteract the slight deformation of the code mold surface (2) of the moving template.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com