Forming method for large concave forging

A forming method and concave technology, applied in the field of forging forming, can solve the problems of low utilization rate of steel ingots, undesired, large net-to-gross ratio, etc., and achieve the effect of improving the utilization rate of steel ingots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

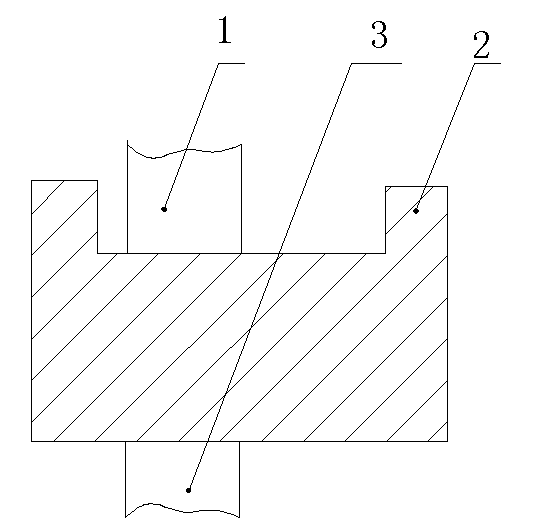

[0014] The concave forgings processed by the present invention are as Figure 5 , 6 As shown in the figure, A is 1590±60mm, B is 460mm, C is 1460±20mm, D is 760±20mm, and E is 320±20mm.

[0015] The forming method of above-mentioned large-scale concave forging is to carry out according to the following steps:

[0016] A. Heat the steel ingot at 1220-1240°C for 6-7 hours. The present invention adopts a longer holding time and a higher initial forging temperature, which can fully heat the steel ingot and ensure forging through;

[0017] B. Upsetting and elongating the forged steel ingot in two times, first press the chamfer, in order to ensure the forging ratio, upsetting the second time to φ1650mm, then drawing and widening to 1460mm×770mm, cutting the tail, stamping, embossing The files and cut pieces are semi-finished products; the two lugs are stretched to 1260mm when pressing the concave file, which is shortened by 200mm. In order to ensure the size of 1460mm, the next...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com