Screw type soil-taking and sample-cutting apparatus

A screw-type, sample-cutting technology, applied in the direction of sampling device, etc., can solve the problem that it is difficult to press the ring knife into the sample, and achieve the effect of improving efficiency and quality, and applying force uniformly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

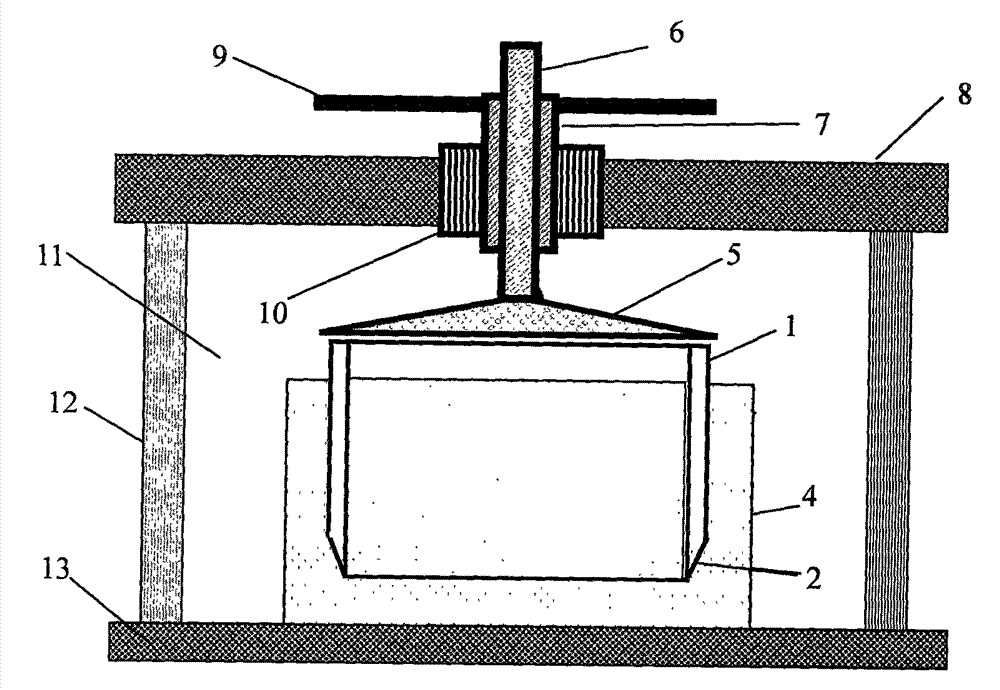

[0011] Design a screw type soil sample cutting device of the present invention, see figure 1 , design a sampling table that can be installed with a screw device, the sampling table includes: a metal circular base 13 with a diameter of 100 mm and a thickness of 10 mm, and four cylindrical support columns 12 with a diameter of 20 mm and a height of 100 mm are fixed evenly and vertically on the edge of the base 13, The upper end of the column 12 is connected with a ring knife seat top plate 8, which is the main force-bearing part when the screw rod of the present invention is propelled. 8 can be easily installed and removed from the support column 12, such as being fixed by buckles or magnets. The ring cutter seat top plate 8 is a metal round platform with a diameter of 100mm and a thickness of 18mm, which is made of rigid hard material and can be turned to bear larger pressure without deformation.

[0012] A bearing 10 with an outer diameter of 40mm, an inner diameter of 20mm, ...

Embodiment 2

[0014] The above-mentioned screw-type soil sampling and cutting device is further improved. On the basis of Embodiment 1, a groove is designed on the bottom plane of the pressure plate 5 at the contact of the pressure plate 5 and the ring knife 1, and the pressure plate 5 When applying pressure to the ring knife 1, the tail of the ring knife 1 can just enter the groove, preventing the pressure plate 5 from sliding relative to the ring knife 1 during the pressure application process. The groove here is circular, concentric with the plane of the cone bottom of the pressing plate 5, the inner diameter of the groove is 62mm, the width is 2mm, and the depth is 2mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com