An engine hydraulic tappet tensioner

A technology of hydraulic tappet and tensioner, which is applied in the direction of transmission, mechanical equipment, belt/chain/gear, etc., which can solve the problem of affecting the reliability of the engine timing system, increasing the difficulty of operator operation, and the difficulty of disassembling the tensioner and other problems, to achieve the effect of wide application range, small friction coefficient, and improved tensioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

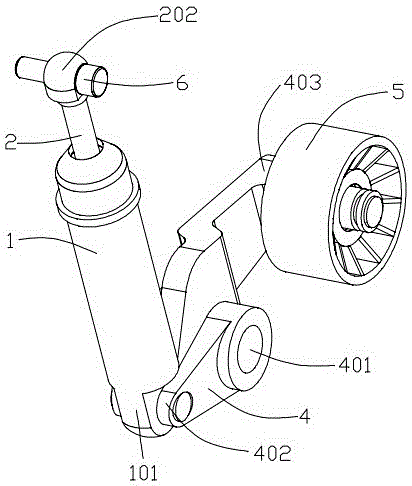

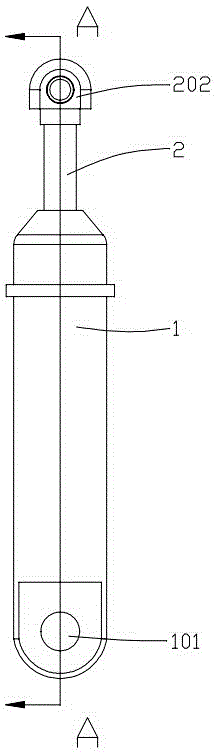

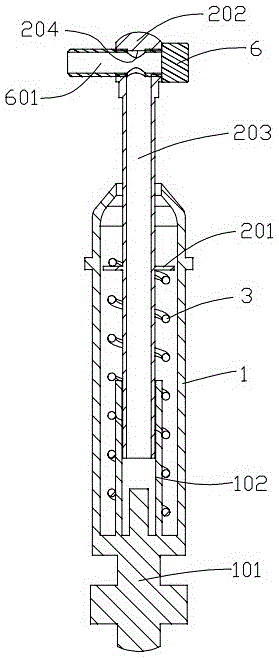

[0018] see figure 1 , an engine hydraulic tappet tensioner, including a tensioner housing 1, a hollow tappet 2 sleeved in the tensioner housing 1, arranged in the tensioner housing 1 and interposed between the tensioner The spring 3 between the tensioner housing 1 and the tappet 2, the spring arm 4 that is pivotally connected to the engine and connects the tensioner housing 1 and a tensioner 5 at both ends, and the tensioner housing 1 One-way valve for internal oil supply (not shown in the figure).

[0019] One end of the tensioner housing 1 is provided with an opening through which the tappet 2 slides and is sealed and sleeved in the tensioner housing 1 . The arm 4 is pivotally connected to the engine through a pivot hole 401 in the middle. One end of the lever arm 4 is a hinged end 402 , which is hinged on the housing outer end 101 located at the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com