Drilling construction gas gushing collection device

A collection device and gas gushing technology, applied in the direction of gas discharge, safety devices, earthwork drilling and mining, etc., can solve the problems of large device volume, complex structure, capsule plugging of boreholes can not achieve the plugging effect, etc., to improve Average progress, removal of potential safety hazards, and effects on job safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

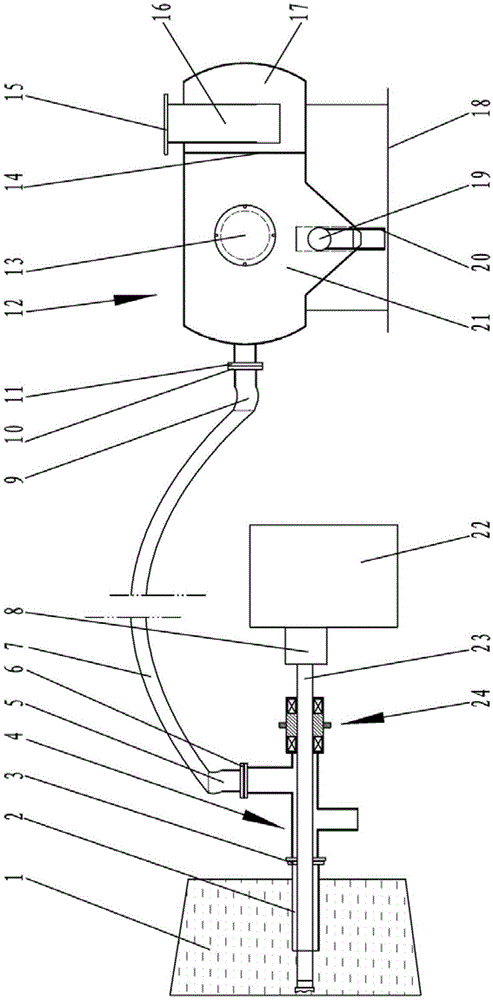

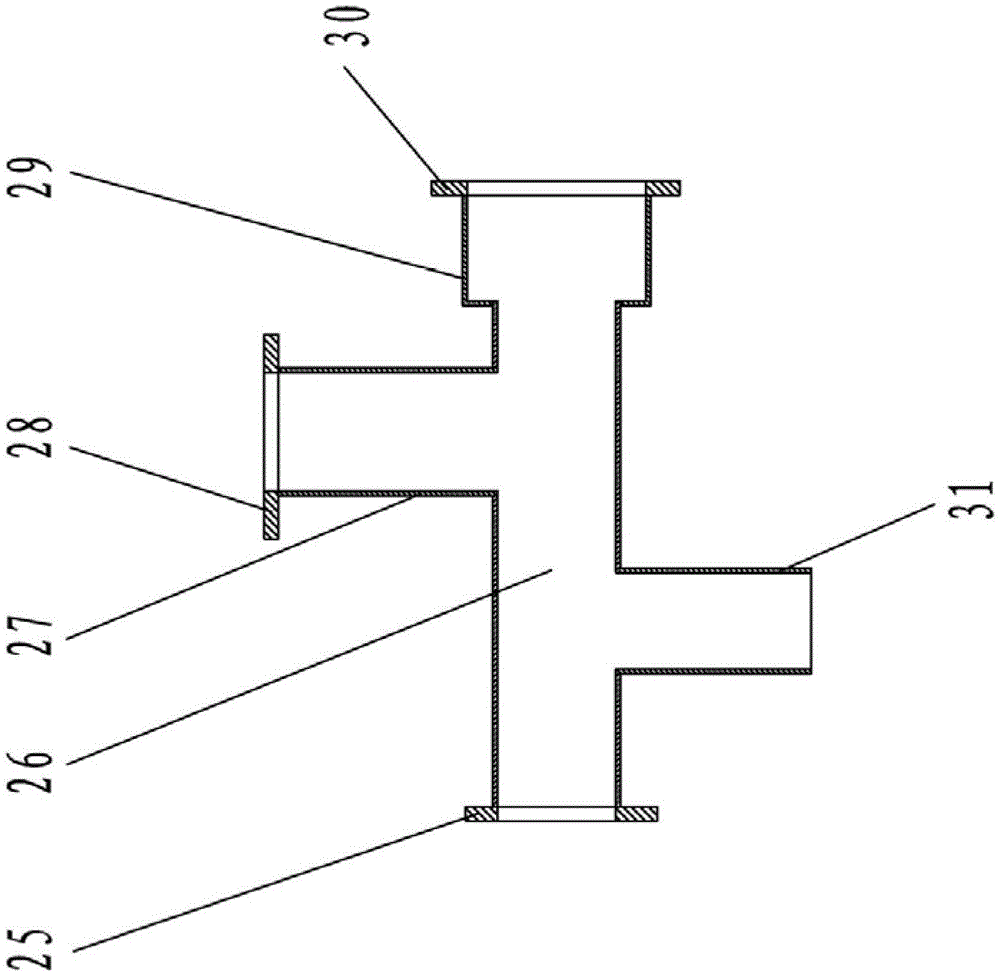

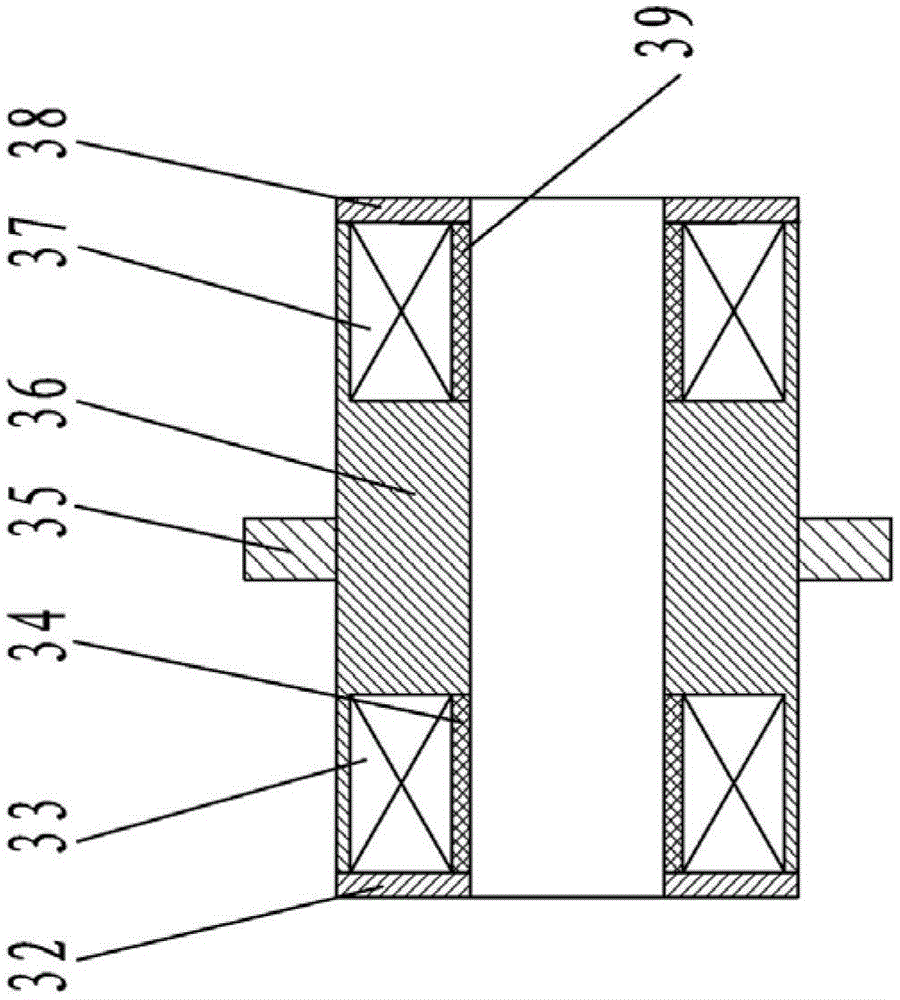

[0012] The specific implementation mode of the present invention is, with reference to figure 1 , including drill hole sealing nesting 2, exhaust water slag assembly 4, follow-up seal assembly 24, gas collection assembly 12, gas collection assembly seat 18, and connecting pipe 7, wherein the two ends of the exhaust water slag assembly 4 are matched and fixed There is a drill hole sealing nest 2 and a follow-up sealing assembly 24. There is a connecting pipe 7 between the exhaust water slag assembly 4 and the gas collection assembly 12. The gas collection assembly 12 is fixed with the gas collection assembly seat 18. Refer to figure 2 , the exhaust water slag assembly 4 includes a drill pipe guide sleeve 26, a drainage slag pipe 31, and a gas outlet pipe 27, wherein the drill pipe guide sleeve 26 has a flange 25 at one end, and the other end is a large-diameter end 29. There is a flange 30 on the large-diameter end 29, and the gas gas outlet pipe 27 and the exhaust water slag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com