Debris flow diversion dam capable of automatically distributing drainage quantity and silt stopping quantity and design method of debris flow diversion dam

A technology for automatic distribution and diversion of dams, which is applied in the remediation of dams, rivers, sea area projects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

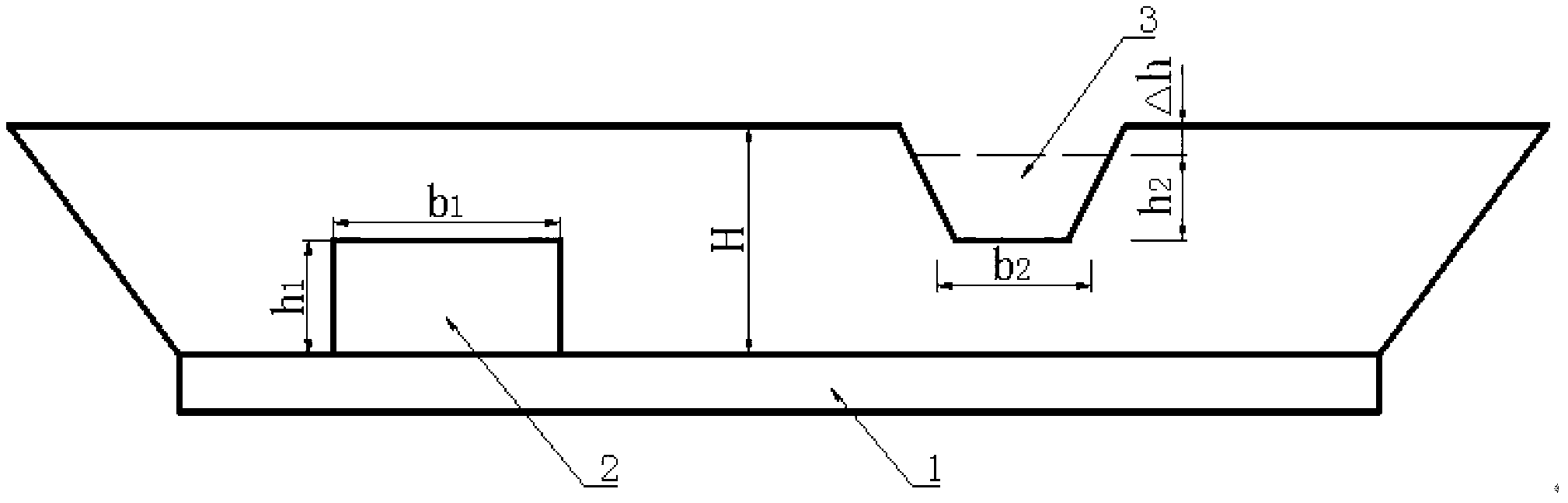

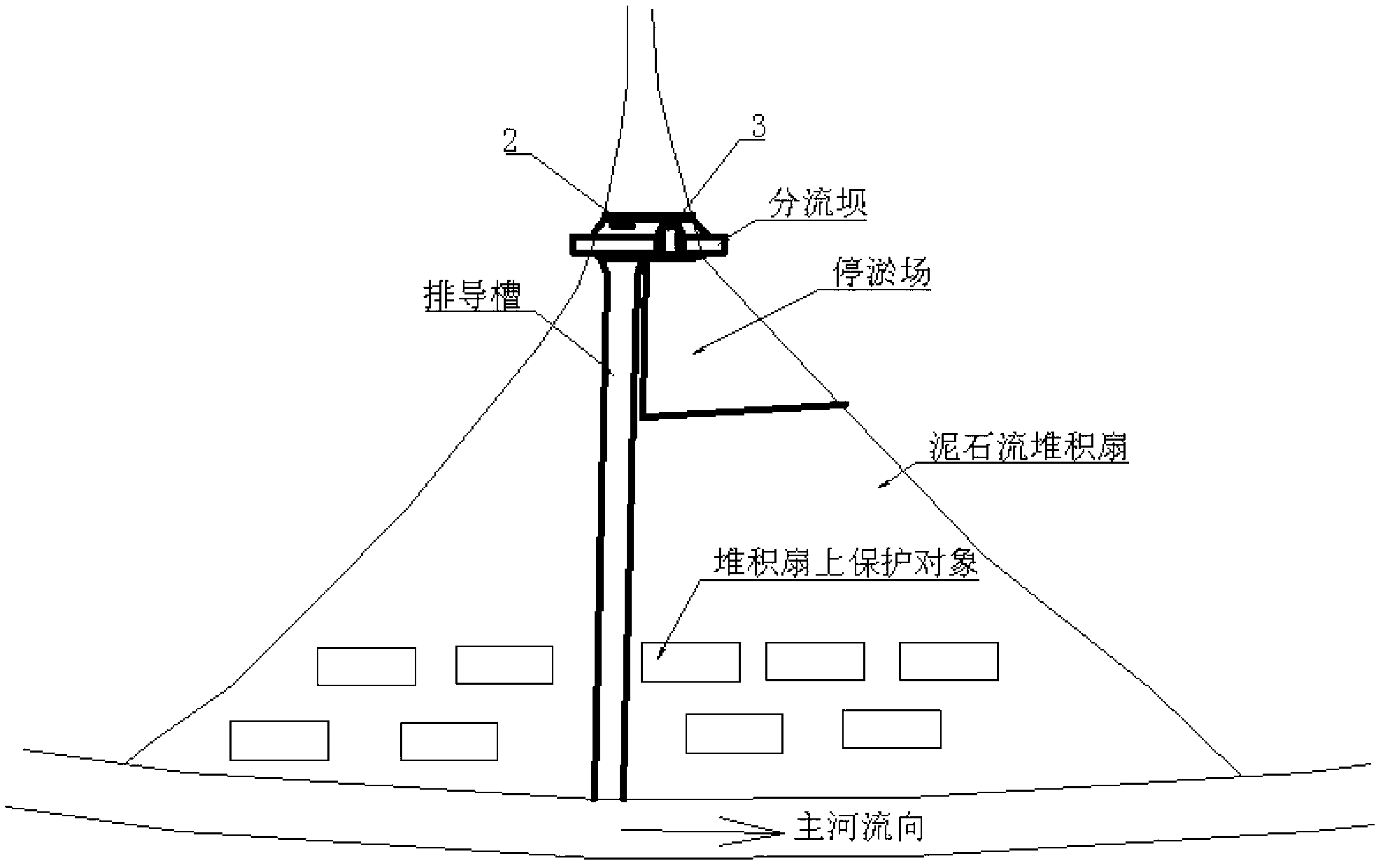

[0027] Such as figure 1 , figure 2 shown. The drainage area of a debris flow ditch is 5.6km 2 , in order to control debris flow disasters, the prevention and control plan of building sand-blocking dams in the ditch, building a silt stop with accumulation fans, and a 4.0m bottom width row channel is adopted. For the 40m wide channel at the top of the accumulation fan, it is proposed to plan a diversion dam to distribute The amount of drainage and silting, the layout of the plane position is as follows: figure 2shown. The debris flow diversion dam that automatically distributes the drainage amount and the silting amount includes a dam body foundation 1 and a dam body body located on the dam body foundation 1; the bottom of the dam body body is provided with a diversion hole 2 connecting the drainage channel, The top of the main body of the dam is provided with a diversion weir 3 connected to the silt stop; The cross-sectional size is determined according to the design f...

Embodiment 2

[0033] Such as figure 1 , figure 2 shown. The same places as in Embodiment 1 will not be repeated, the difference is that the drainage area of a certain debris flow ditch is 16.8km 2 , using the prevention and control plan of building a group of sand dams in the ditch, building a silting field with accumulation fans, and a 6.0m bottom width row of guide channels. It is proposed to plan a diversion dam to distribute the drainage volume and silting volume. The design flow rate Q of the guide groove drainage 84.0m 3 / s, the design flow Q of the parking lot deposit 62.0m 3 / s. The main body of the dam body is made of masonry material.

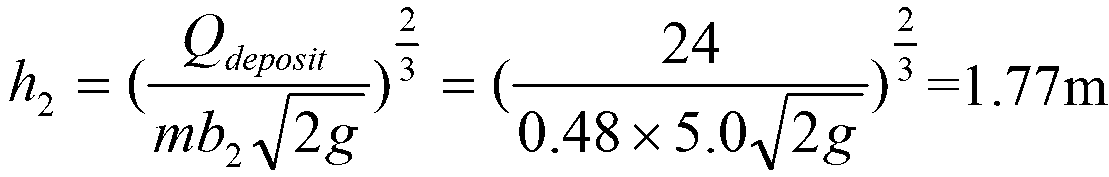

[0034] In the first step, the average width of the diversion weir 3 is preliminarily set b 2 is 5.0m, and the discharge coefficient m is taken as 0.46 according to the main material of the dam body, according to the formula h 2 = ( Q ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com