Method of lifting steel box beam with steel lifting bands and hydraulic device

A technology of hydraulic devices and slings, which is applied to the erection/assembly of bridges, bridges, bridge construction, etc., which can solve the problems of high labor intensity, high cost of block assembly, poor stability, etc., and achieve simple, stable and reliable structure and complete construction Increased level, excellent effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

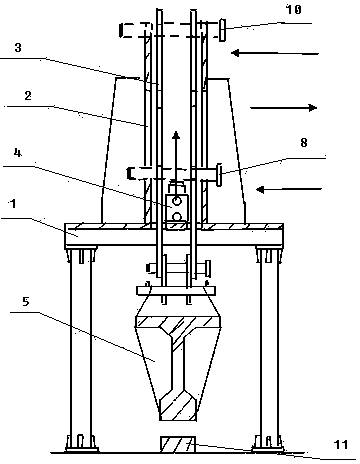

[0021] The present invention adopts steel sling and hydraulic device to lift the method for the prefabricated beam, and it is characterized in that:

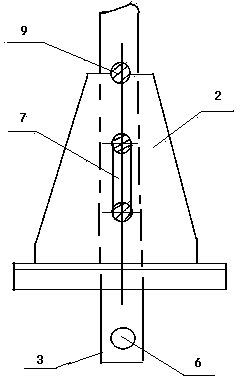

[0022] 1. According to the size and weight of the finished beam, make steel slings. There are several pin holes arranged up and down on the steel slings; for the convenience of use, the pin holes on the steel slings are set equidistantly.

[0023] 2. Lift and connect the left and right two steel slings with the two ends of the finished beam; and install an electro-hydraulic jack as a power device for lifting the finished beam. When the ejector rod of the electro-hydraulic jack reciprocates, it can push the left and right The two steel slings reciprocate up and down; beside the left and right two steel slings, a support plate is respectively set up, and a strip-shaped slot hole is set on the support plate, and several pin holes correspond to the steel slings. holes; both the support plate and the electro-hydraulic jack are suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com