High-load retarder with welding type piston

A deceleration jack and high-load technology, which is applied in the direction of railway car body parts, track brakes, transportation and packaging, etc., can solve the problems of inability to judge the speed in different stages, and the large flow area of the speed judgment, so as to reduce the production cost and work The effect of plumping and reducing the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

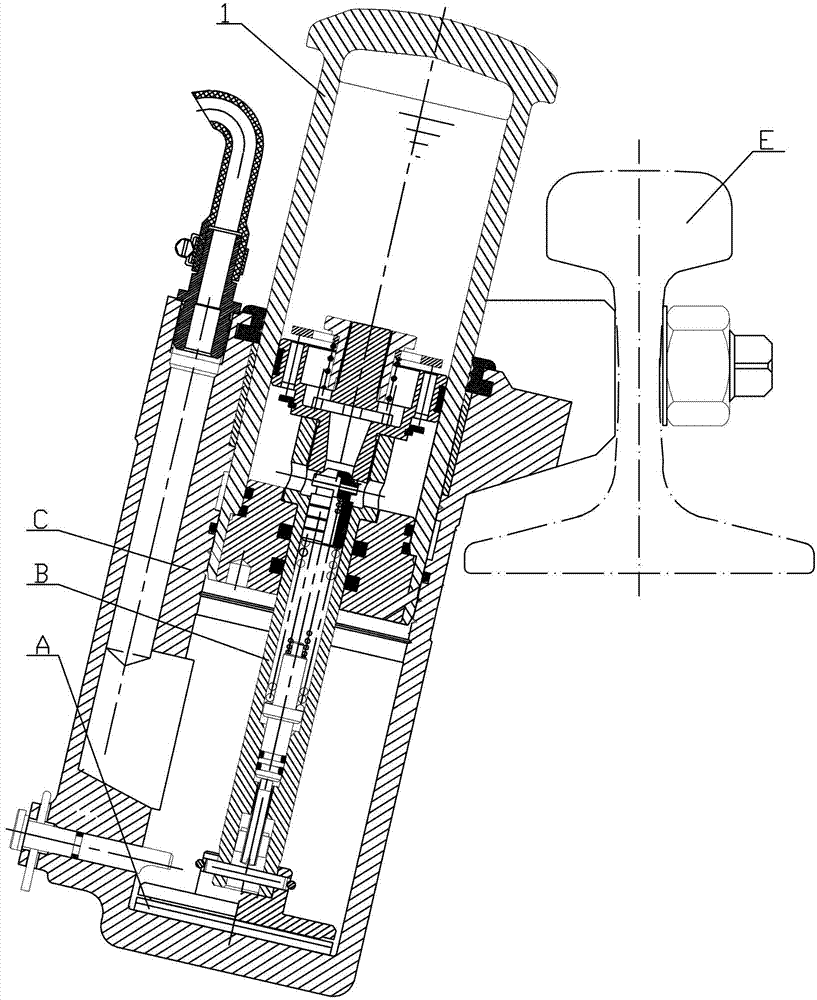

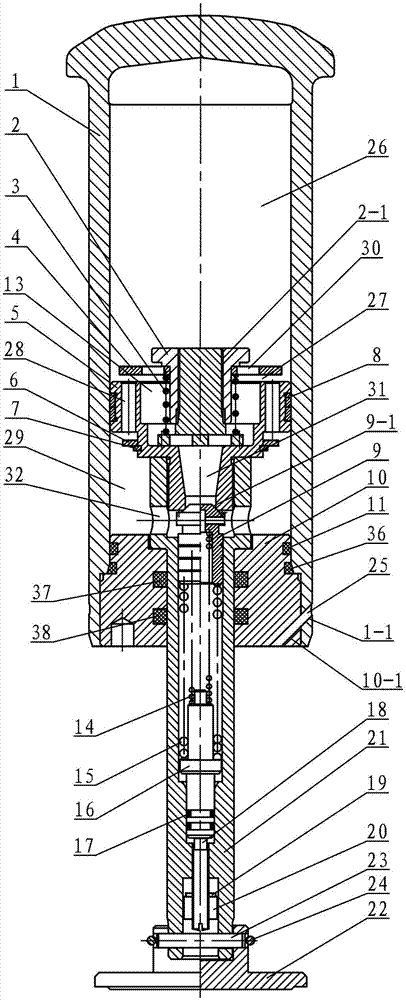

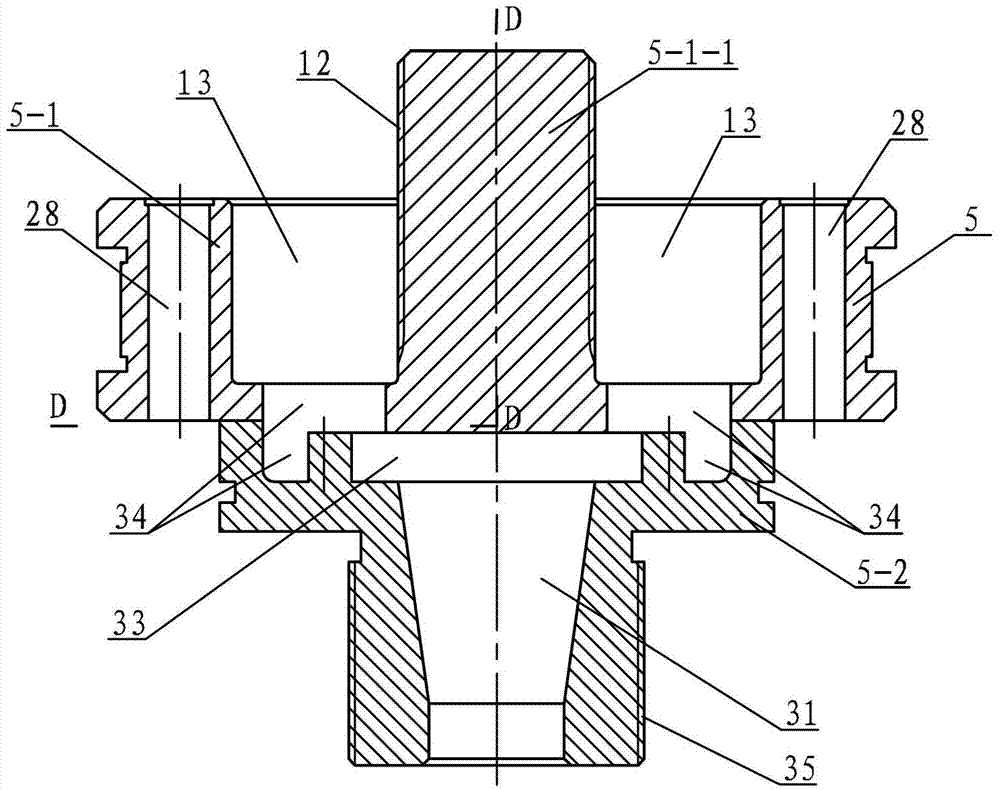

[0013] Specific implementation mode one: combine Figure 1 to Figure 6 Describe this embodiment. This embodiment includes a sliding cylinder assembly B and a housing C. The sliding cylinder assembly B includes a sliding cylinder 1, a speed valve seat 2, a speed valve spring 3, a speed valve plate 4, a piston 5, and a return stroke Valve plate 6, retaining ring 7, support ring 8, pressure valve stem 9, sealing cover 10, pressure valve inner spring 14, pressure valve outer spring 15, spring seat 16, fifth O-ring 17, pressure regulating screw 18, Washer 19, lock cap 20, piston rod 21, anti-shock seat 22, connecting pin 23, snap ring 24 and pin 25, the piston rod 21 is equipped with lock cap 20, washer 19, pressure regulating screw 18, The fifth O-shaped sealing ring 17, spring seat 16, pressure valve outer spring 15, pressure valve inner spring 14 and pressure valve stem 9, the piston 5 is composed of an upper piston 5-1 and a lower piston 5-2, and the upper piston 5-1 A second ...

specific Embodiment approach 2

[0014] Specific implementation mode two: combination figure 2 Referring to this embodiment, the sliding cylinder assembly B of this embodiment further includes a first O-ring 11 , and the first O-ring 11 is disposed between the sealing cover 10 and the sliding cylinder 1 . The first O-ring 11 is used to increase the sealing performance between the sealing cover 10 and the sliding cylinder 1 . Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0015] Specific implementation mode three: combination figure 2 Describe this embodiment, the sliding oil cylinder assembly B of this embodiment also includes a second O-ring seal 36, and the second O-ring sealing ring 36 is arranged below the first O-ring sealing ring 11 and is located between the sealing cover 10 and the sliding oil cylinder. between 1. The second O-ring 36 enables better sealing between the sealing cover 10 and the sliding cylinder 1 . Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com