Windshield wiper connector

A connector and wiper technology, which is used in vehicle cleaning, vehicle maintenance, transportation and packaging, etc., can solve problems such as reducing production costs, and achieve the effects of improving low adaptability, complex structure and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

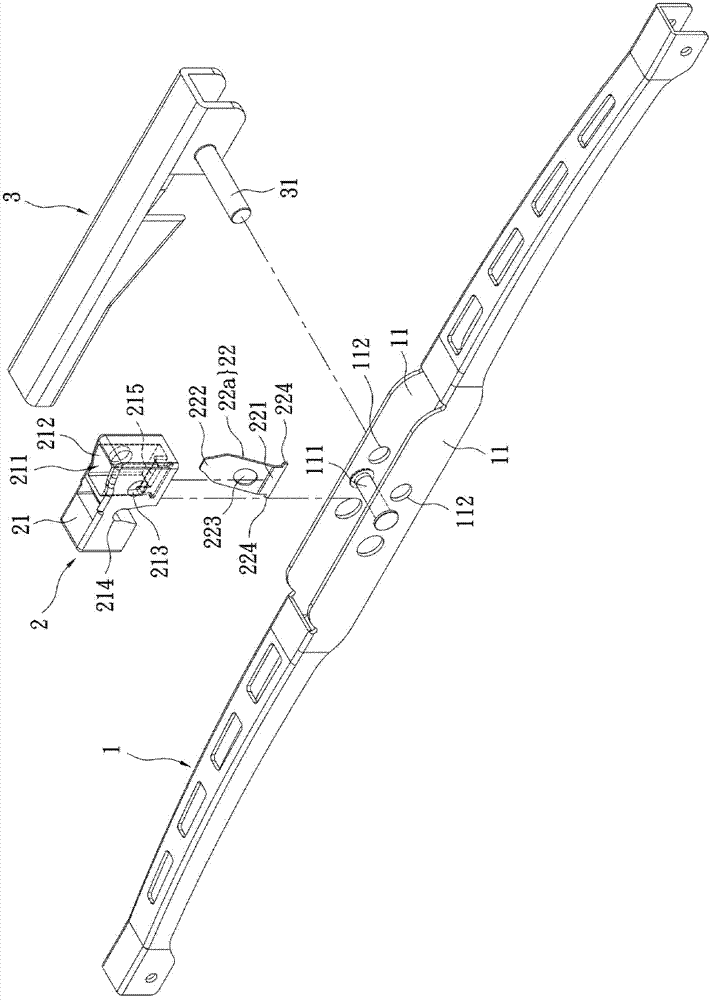

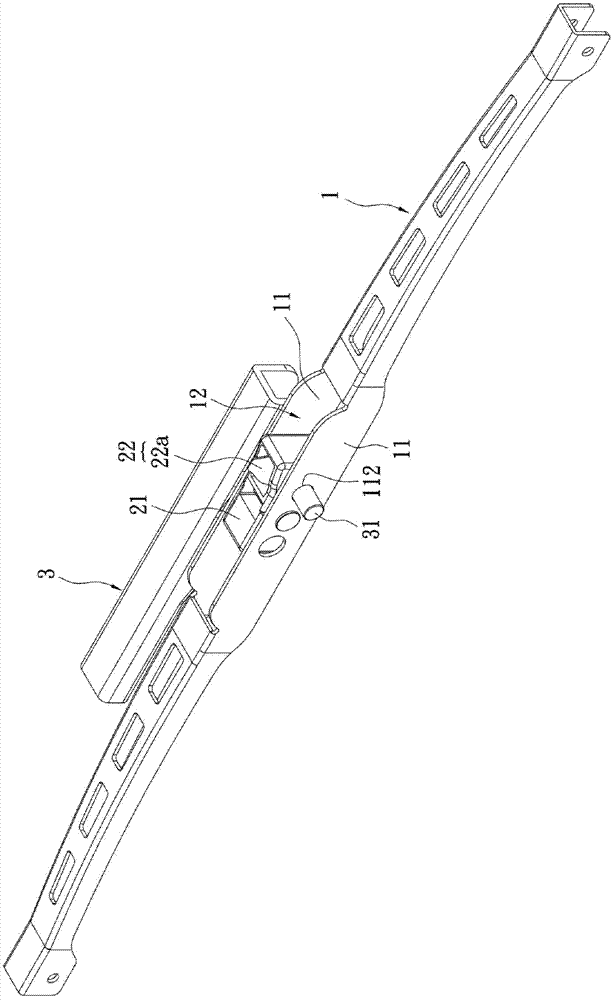

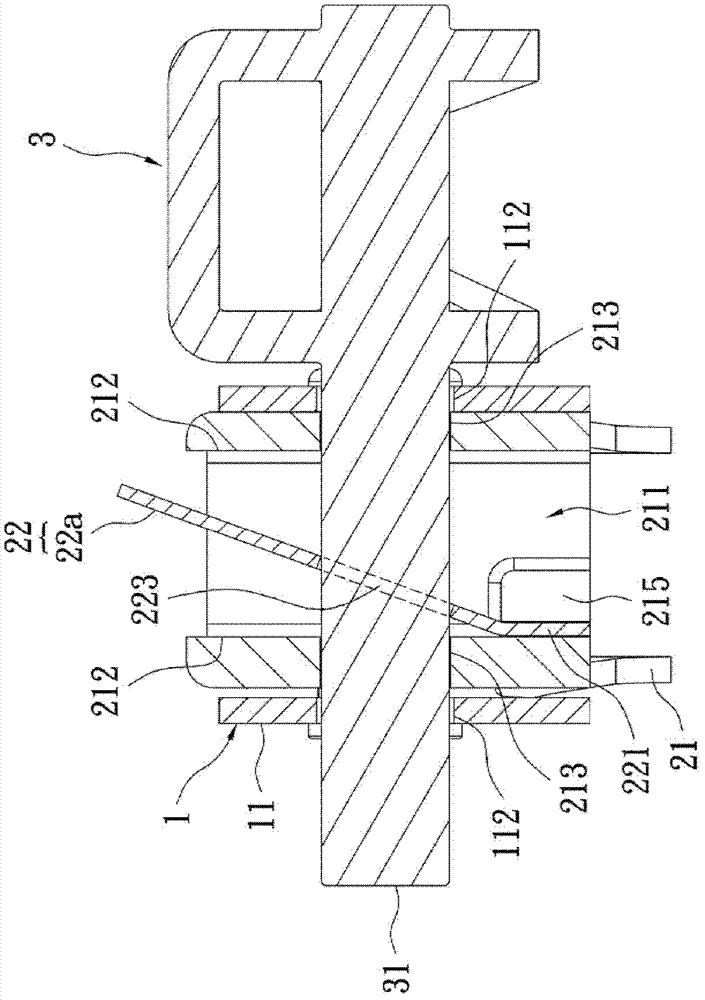

[0083] see Figure 1 to Figure 3 As shown, the wiper connector 2 of the present invention is disposed on a wiper bone 1 , and the wiper bone 1 has two wiper bone walls 11 , two mounting holes 112 and a receiving space 12 . Wherein, the two installation holes 112 are set on the two wiper bone walls 11 , and the accommodating space 12 is formed between the two wiper bone walls 11 . The wiper connector 2 is disposed in the accommodating space 12 of the wiper bone 1 , and the wiper connector 2 includes a connector body 21 and an elastic piece 22 .

[0084] see figure 1 , the connector body 21 has a recessed portion 211, an engaging portion 214 and a stop portion 215 (please also refer to image 3 ). The connector body 21 has two sidewalls 212 located on two sides of the concave portion 211 . The two side walls 212 respectively have a receiving portion 213 , and the two receiving portions 213 coaxially and oppositely penetrate through the two side walls 212 . The engaging port...

Embodiment 2

[0096] see Figure 5A and Figure 5B As shown, this embodiment provides another form of the elastic piece 22 that is different from that described in the first embodiment.

[0097] The elastic piece 22 is a spiral plate 22b, one end of the spiral plate 22b is a fixing portion 221, and a dialed portion 222 of the spiral plate 22b extends from the fixing portion 221. A notch 223 is formed in the dialed portion 222 . Wherein the fixing part 221 is embedded as image 3 In the connector body 21 , the screw plate 22 b is disposed in the recessed portion 211 .

[0098] see image 3 ,Will image 3 The flexible flat plate 22a is replaced by a spiral plate 22b. The notch 223 is surrounded by the spiral plate 22 b and corresponds to the two receiving portions 213 on the two side walls 212 . In other words, the notch 223 is disposed between the two receiving portions 213 . After the pin 31 of the plug-type wiper rod 3 passes through the three holes, the inner edge of the notch 223 ...

Embodiment 3

[0101] The difference between this embodiment and Embodiments 1 and 2 lies in the shape of the connector body and the shrapnel, which are described in detail as follows:

[0102] see Image 6 , Figure 7 and Figure 8 As shown, the wiper connector 2' of this embodiment has a connector body 21', the connector body 21' includes a receiving portion 213, and the receiving portion 213 is recessed downward from the top surface of the connector body 21' to form a groove shape. The elastic piece 22 is at least one "C"-shaped elastic piece 22c, one end of the "C"-shaped elastic piece 22c has a fixing portion 221, and an inner edge of the "C"-shaped elastic piece 22c forms a gap 223. The fixing part 221 of the "C" shaped elastic piece 22c is inserted into the connector body 21', and the notch 223 corresponds to the receiving part 213 of the connector body 21' and is slightly smaller than the receiving part 213.

[0103] When the pin 31 of the pin-type wiper lever 3 is combined with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com