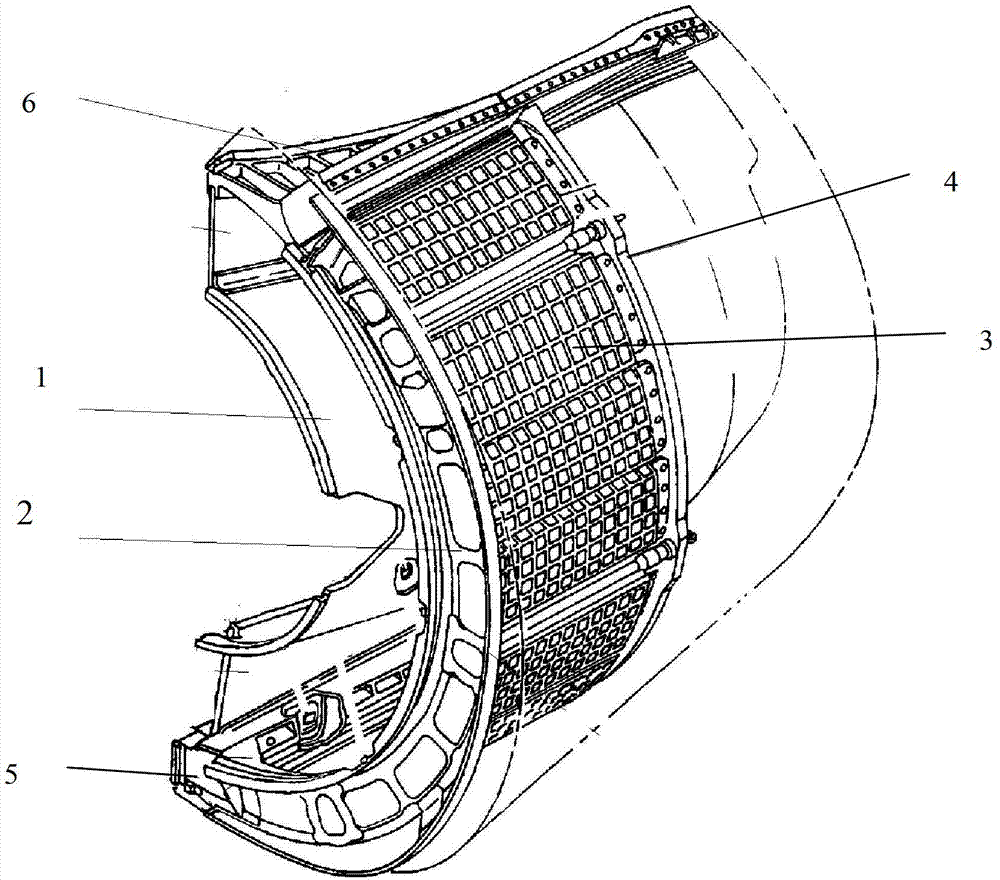

Maintaining clamp for jet braking C duct of civil aviation passenger plane

A technology for ducts and airliners, which is applied in the repair of reverse thrust C ducts and repair fixtures for reverse thrust C ducts of civil aviation airliners. It can solve problems such as deformation, and achieve the effects of avoiding deformation, simple composition and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

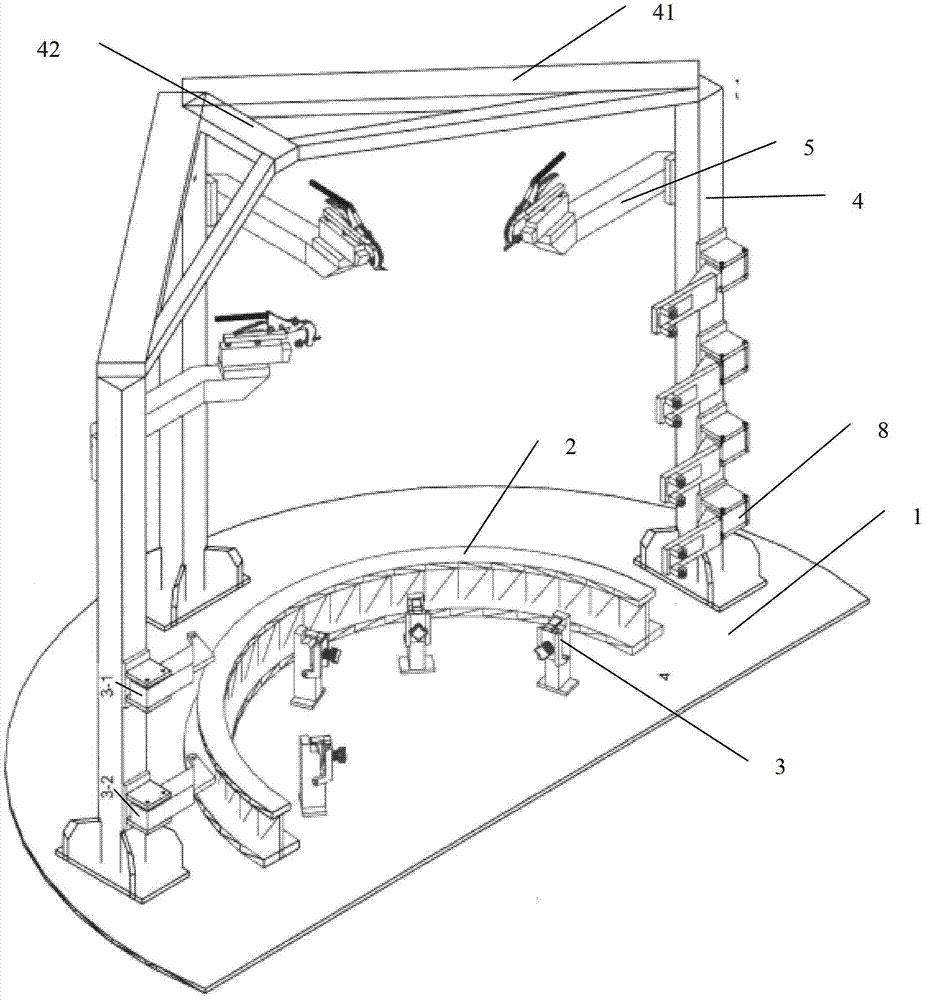

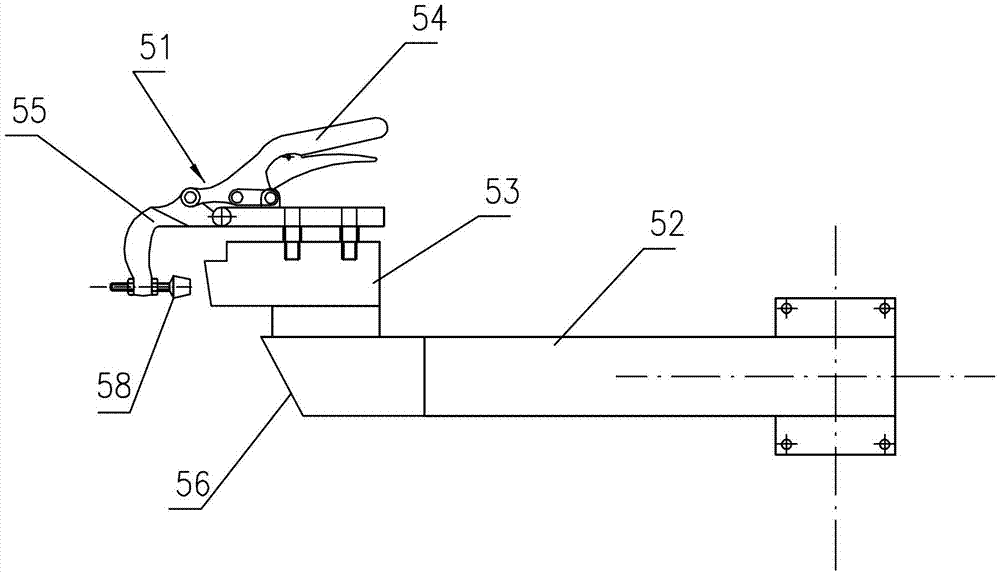

[0034] Such as Figure 2-12 As shown, it is a repair fixture for reverse thrust C duct of civil aviation airliner of the present invention, which is suitable for overhauling reverse thrust C duct of 737 type civil aviation airliner. It includes a horizontal tray 1, a support rail 2 arranged on the tray 1, four lower locking clips 3 arranged on the tray 1, three uprights 4 and corresponding upper locking clips 5 on each upright, supporting The track 2 is arc-shaped and adapts to the shape of the V-shaped groove of the torque box of the reverse thrust C duct to support the V-shaped groove of the torque box on the top surface of the supporting track 2. The column 4 is located on the periphery of the supporting track 2 and along its Circumferentially distributed and enclosed as a working space for vertically placing reverse thrust C ducts, horizontal connecting rods 41 are arranged between the tops of the columns 4, and the connecting rods 41 connect adjacent columns 4. The conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com